TDKDR dryer suitable for drying various mineral materials (like ore slag, sand stone, clay, dolomite, kaolin, coal gangue, slag-powder mixing material, coal ash and gypsum), light unbonding light biomass materials (like corncob, carbon black, ceramsites, sawdust, bamboo shaving, wood chip and recycled plastics) and waste metal scrap (like iron powder, aluminum scrap, drillings and bottle chip).

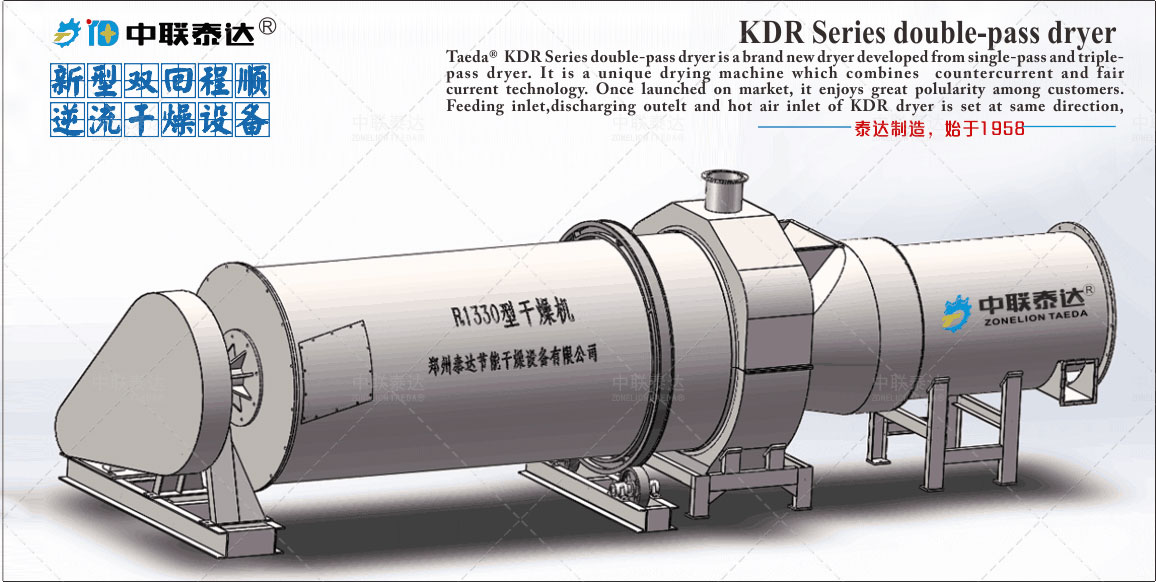

TDKDR drying system is a brand new dryer developed from previous single-pass and first generation triple-pass dryer. It is a unique drying machine which combines countercurrent and fair-current technology on the market. Once launched to market, it enjoys great popularity among customers. Feeding inlet, discharging outlet and hot air inlet of TDKDS dryer is set at the same direction, which greatly provide convenience for operation. Double-pass installed with inspection door, which is more beneficial for later maintenance and trouble shooting.

Taeda double pass dryer is suitable for drying various mineral materials (like ore slag, sand stone, clay, dolomite, kaolin, coal gangue, slag-powder mixing material, coal ash and gypsum), light unbonding light biomass materials (like corncob, carbon black, ceramsites, sawdust, bamboo shaving, wood chip and recycled plastics) and waste metal scrap (like iron powder, aluminum scrap, drillings and bottle chip ).

Taeda TDKDR double pass dryer adopts two drum structure. Materials will enter dryer from inner drum and exchange heat with high temperature hot air. Then, materials will contact with hot air countercurrently while being dischareged out of external drum. Countercurrent and faircurrent drying process are finished in one dryer. TDKDR dryer can reach to low final moisture and occupies less area.

Taeda TDKDR dryer adopts pulley driving for small model. There is maintenance board at end for disassembly and maintenance convenience. It is featured in high mechanical level, stable running and smooth drying performance. Large model adopts two-roller driving. Whole dryer is placed horizontally and cause less abrasion. Therefore, TDKDR dryer consumes less quick wear parts.

Owing to small body and simple driving structure, TDKDR dryer costs less investment than dryer with same capacity. It is suitable for projects which are sensitive to investments cost. Even though its price is not high, TDKDR dryer adopts scientific structure and superior texture, which makes it service life longer and save customer' concerns.

Whole drying system can be configured flexibly. We can provide feeding, heat source, conveying, dust collecting, discharging and packing units ba

| Model | Capacity | Feeding moisture | Final moisture | Brand | Power | Transmission mod | Support roller No. |

| (t/h) | % | % | ZONELION TAEDA | (Kw) | Group | ||

| TDKDR1025 | 5-10 | 5-25 | 0.5-4 | 5.5 | Pulley | 1 | |

| TDKDR1330 | 10-15 | 5-25 | 0.5-4 | 7.5 | 1 | ||

| TDKDR1535 | 15-25 | 5-25 | 0.5-4 | 11-15 | 1 | ||

| TDKDR1840 | 25-30 | 5-25 | 0.5-4 | 15 | Roller | 2 | |

| TDKDR2046 | 30-40 | 5-35 | 0.5-4 | 22 | 2 | ||

| TDKDR2555 | 35-45 | 5-35 | 0.5-4 | 30 | 2 | ||

| TDKDR2865 | 40-50 | 5-35 | 0.5-4 | 30 | 2 | ||

| TDKDR3070 | 35-60 | 5-35 | 0.5-4 | 45 | 2 | ||

| TDKDR4090 | 35-70 | 5-40 | 0.5-4 | 55 | 2 |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.