【Capacity】: 0.2-9t/h

【Product moisture】: ≤10%

【Applicable materials】: As a ground-breaking drying machine, Taeda blood protein dryer can replace spraying drying technology to dry both whole blood and plasma protein. It is featured in high drying efficiency, less running cost, low investment cost, high safety performance and good sterilization effect. Taeda blood meal dryer can avoid protein denaturalization caused by over heat. Dry products can be used as high-end feedstuff additives to replace fish/meat meal and skim milk powder.

Since history, spray-dried plasma protein powder and blood cell protein powder are two high-quality animal protein sourcing from animal blood. Owing to policy regulating, this kind of protein powder is prohibited to feed cud chewer. Except for that, effect and nutritional ingredients in blood protein meal are far more superior to fish meal. What’s more, in USA, Canada and other developed countries, it can replace skim milk powder to breed Suckling pigs and weaned piglets.

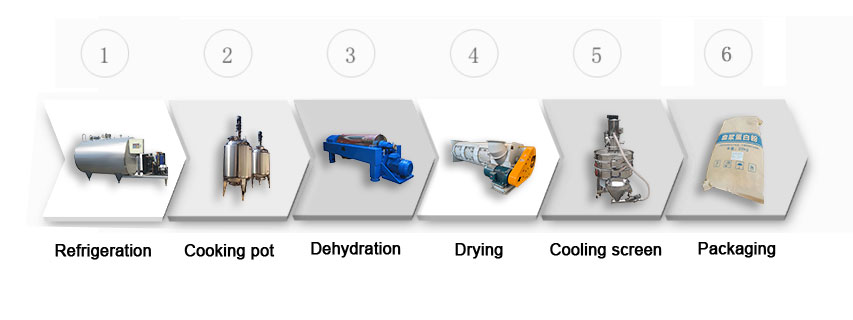

Taeda blood meal dryer is specially designed for drying blood which is byproduct form slaughter house. Because the production process starts from cooking corrugating, the dryer is also called corrugated blood dryer. Compared with traditional spray drying technology, its superiority mainly lies in low running cost and low investment cost. Taeda blood meal dryer can use either common fuel like natural gas or other renewable energies like wood and wood pellet after heat exchanging as fuel.

This new type blood meal dryer enjoys great popularity among Chinese customers. Besides low running cost, high performance cost ratio and good sterilization effect, it can also prevent product over heat and denaturalization of protein. Dried products can be used as high-end feedstuff additives. Application of dried blood meal can bring sound economic benefit to farm. Taeda blood meal dryer worth popularization and application.

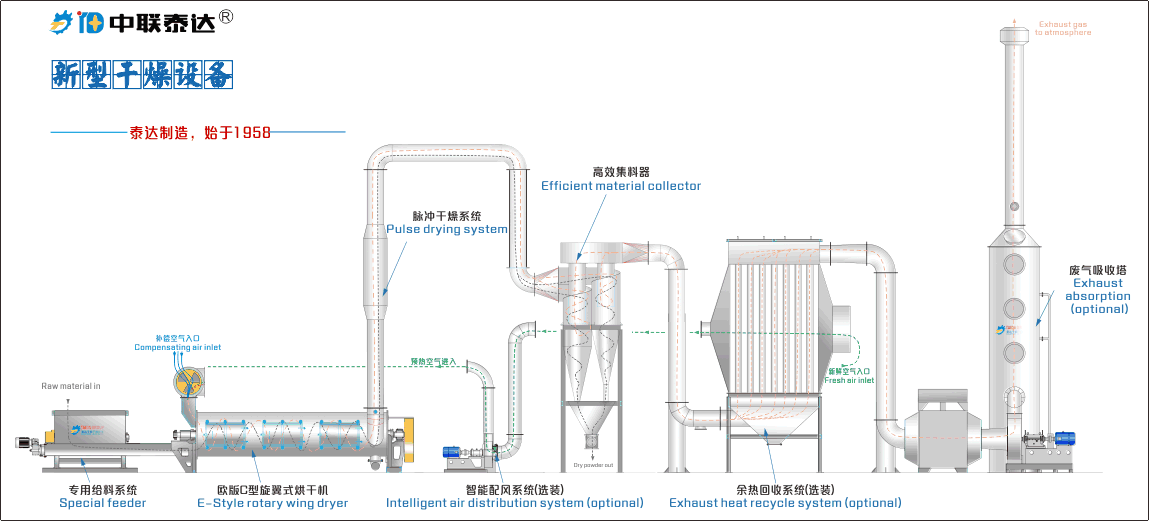

Taeda BM(Blood Meal) dryer fully takes features of BM into consideration during designing process. Whole drying system is characterized by mild uniform drying process and good sterilization effect. Overheat and protein denaturalization are well avoided. Inner structure of dryer is re arranged so that to solve difficulties for drying BM. Whole BM drying system is featured in simple operation, smooth production, and low energy consumption.

Taeda BM dryer adopts new drying concept which can meet continuous drying requirements of blood from slaughter house and make final products more suitable for feedstuff additives. Whole drying and dehydration process is gentle. With better quality, final product can be widely used in aquaculture, pig, broiler and other breeding industries.

Taeda BM dryer adopts rotary wing structure and scientific design. Blood meal are dried mildly in dryer. Meanwhile, residence time can be flexibly adjusted so that to guarantee good product quality. For same capacity, air volume need for blood meal dryer is much less than spraying drying tower. Therefore, Taeda BM dryer holds high energy utilization and low thermal loss, it is more energy saving.

The layout of the new BM specific dryer is flexible and versatile, and it is not limited by any site, and only requires a horizontal hardened ground. Professional team provides one-step service and customizes suitable equipment based on present condition.

| Model | BM-OSC | ||||||

| I | II | III | IV | V | VI | ||

| Capacity | (t/h) | 0.2 | 0.5-1 | 1-2 | 3-5 | 6-7 | 8-9 |

| (t/d) | 5 | 20 | 50 | 120 | 160 | 200 | |

| product volume | (t/d) | 2 | 10 | 20 | 50 | 70 | 100 |

| Heat source | Direct heating(gas) | Indirect heating exchanging (pellet, wood, coal and etc.) | |||||

| Product moisture | <10%(Adjustable) | ||||||

| Installed power | (kw) | 20 | 30 | 55 | 120 | 160 | 230 |