Generally speaking, majority of antibiotic dregs are biomass fermentation dregs whose main ingredients are corn flour, dextrin and so on. Biomass components are source of nutrients in the growth process of antibiotic bacteria. When available bacteria grow to a certain stage, they are extracted with extractants and fermented slag is inactivated before landfill and composting disposal. However, with the continuous development of pharmaceutical companies, output amount of fermented dregs is also increasing. Cost of landfill and composting is also getting higher and higher. Deterioration of landfill sites and composting environment has become more and more difficult to meet the increasingly stringent environmental protection requirements, so there is an urgent need for a new more environmentally friendly treatment method. At the same time, feed industry generally calls for non-antibiotics feed. Therefore, technical routes of drying, pelleting, and incineration are more feasible and effective.

Today, I will recommend a treatment method that can harmlessly dispose, reduce amount and recycle useful things, which has good social, environmental and economic benefits.

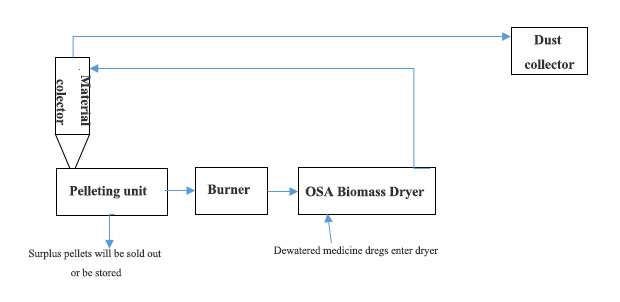

Please refer to below process chart:

Now, I will explain from material flow:

First, the produced biomass fermentation dregs need to be dehydrated. Due to the low calorific value and high moisture content of the biomass fermentation dregs, a plate and frame filter press or a belt dehydrator can be selected for dehydration. The dehydrated medicine slag is dried in the European dryer. After drying, the dried slag is directly dried by airflow and then falls into the silo of the granulator for granulation. According to the experience of ZONELION TAEDA® and customer feedback, the dried low calorific value of the latter slag is greater than 800kcal/kg. After being compressed into φ8mm particles by the granulator, it is more compact and the calorific value is further improved, which can meet the combustion requirements of the pellet burner. The hot air generated by the burner is used by the European dryer, and the surplus biomass particles can be exported or stored for use. After being extruded, the medicine slag is burned in the combustor, so that the decaying organic matter is burned at high temperature (the temperature of the second combustion chamber is greater than 1100 ℃) and becomes inorganic. The pathogenic organisms are destroyed by the high temperature incineration, resulting in incombustible components. And the slag after burning to achieve a large degree of reduction.

Now, I will introduce air flow:

The combustion air supply system of the heat source part is sent to the burner by the blower according to the combustion-supporting air required in the combustion stage of the slag, and is used as exhaust gas after passing through the burner, hot blast stove, European slag dryer, collector, and dust collector. Enter the exhaust gas treatment unit.

After the actual production operation, the process system adopts the process idea of antibiotic fermentation drug residue dryer + granulation + combustion, which can realize drug residue reduction, harmlessness, and resource treatment. The technology is advanced, and the exhaust gas can meet the emission standards. Achieving good social, environmental and economic benefits is of great significance to the sustainable development of enterprises.

Our customers who adopt this kind of process are fully satisfied with OSA production equipment and drying process.

Relative news