【Capacity】:

【Initial moisture】: 55-68%

【Applicable materials】: Taeda spent coffee grounds dryer is a breakthrough drying equipment which makes use of direct heating method to realize coffee grounds drying. It is featured in high drying efficiency and product moisture can be adjusted from 8% to 20%. Compared with steam dryer, coffee grounds dryer can produce better quality final product and consumes low running cost. Taeda spent coffee grounds dryer is regarded as a cost effective drying equipment. After drying, dry coffee grounds can be widely applied for feedstuff additive, fertilizer, bio char and soil conditioner.

Taeda coffee grounds dryer enjoys great popularity in Japan, Korea and Vietnam. Based on breakthrough of steam coffee grounds drying line, this new special drying machine is developed for high-moisture coffee grounds and similar materials drying particularly. It adopts common fuel as heat source and moisture of spent coffee grounds can be reduced to 8% from 55%-68% one time. In addition, according to application field, output moisture content of Taeda spent coffee grounds dryer can be flexibly adjusted. It perfectly solve disadvantages of steam dryer for drying coffee grounds like low capacity, high energy consumption and high investment cost resulted from multi-stage sets steam dryer configuration. Therefore, Taeda SCG dryer can transfer Spent Coffee Grounds into resources, produces good social benefit, ecological benefit and economic benefit.

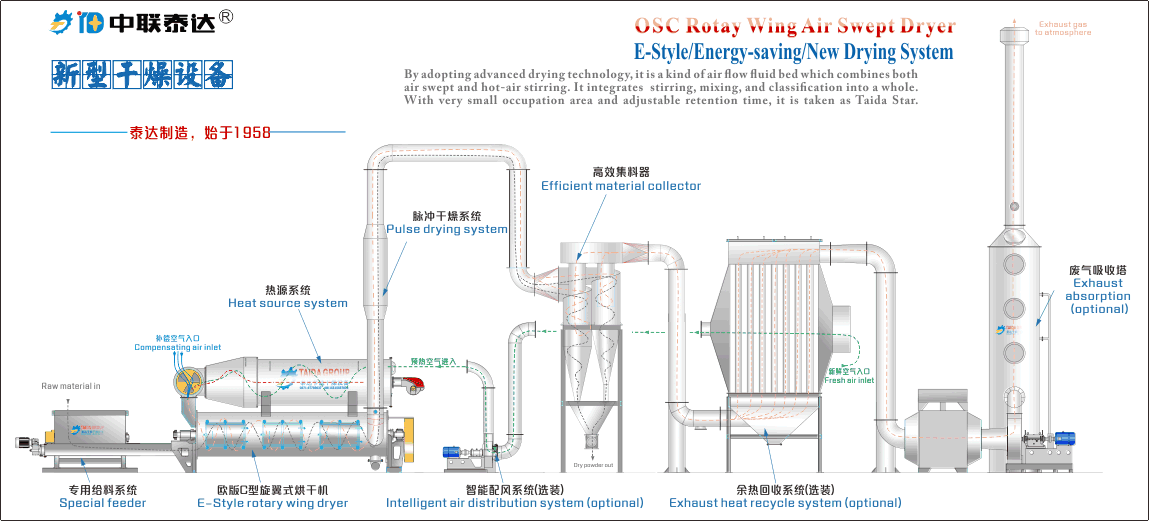

SCG dryer mainly consists of heat source, feeder, dryer, discharging device, ID fan, exhaust gas purification device and electrical cabinet. When entering dryer, wet coffee grounds form fluid bed quickly under function of special designed rotary wing combination structure inside dryer drum. What’s more, whole drying chamber is fully occupied by coffee grounds particles. Materials will evenly scatter and fully contact with hot air, which speeds up heat and mass transfer process. Upon drying process completion, dried SCG will flow out from discharging valve as final dry products.

Taeda SCG dryer fully takes features of SCG into consideration during designing process like flying dust, easy burning, and high moisture. Inner structure of dryer is re arranged so that to solve difficulties for drying SCG. Whole SCG drying system is featured in simple operation, smooth production, large capacity and low energy consumption.

Taeda SCG dryer adopts new drying concept which can meet continuous drying requirements of wet SCG and make final products more suitable for feedstuff additive, fertilizer, bio char and soil conditioner. Whole drying and dehydration process is gentle and final product holds better quality.

Taeda SCG dryer adopts rotary wing structure and scientific design. For same capacity, its total length is only a quarter of the steam dryer. Therefore, Taeda corncob dryer holds small footprint and its heat radiating area is smaller than common dryer. With high energy utilization and low thermal loss, it is more energy saving.

The layout of the new SCG material specific dryer is flexible and versatile, and it is not limited by any site, and only requires a horizontal hardened ground. Professional team provides one-step service and customizes suitable equipment based on present condition.

| Model | OSC | ||||||

| I | II | III | IV | V | VI | ||

| Capacity | (t/h) | 0.2 | 0.5-1 | 1-2 | 3-5 | 6-7 | 8-9 |

| (t/d) | 5 | 20 | 50 | 120 | 160 | 200 | |

| product volume | (t/d) | 2 | 10 | 20 | 50 | 70 | 100 |

| Feed moisture content | 60%(Wet coffee grounds) | ||||||

| Product moisture | <15%(Adjustable) | ||||||

| Installed power | (kw) | 20 | 30 | 55 | 120 | 160 | 230 |