Capacity: 0.3-80t/h

Working mode: 24hours per day

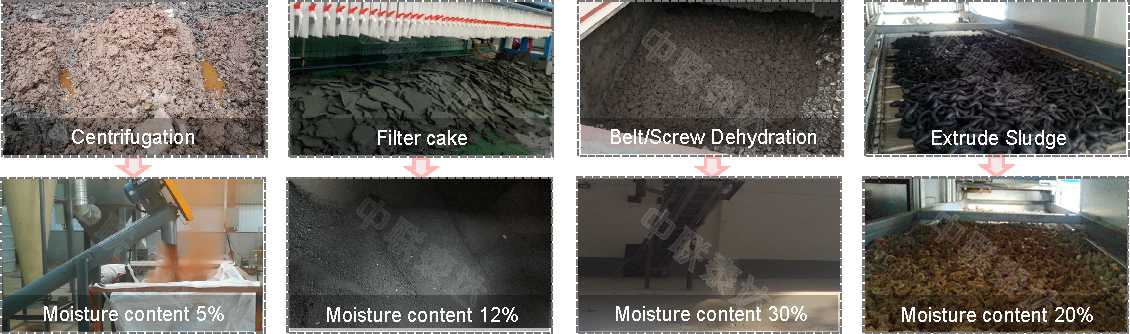

Applicable material: Various sludge

Sludge is a kind of by products produced during waste water treatment process. Generally, there are many harmful matters and heavy metals contained in sludge. Without complete disposal, sludge will cause secondary pollution. Rational deep drying disposal process can not only avoid pollution, but also can make wastes into useful resources. Biomass wastes can be transferred into high-quality fertilizer, even some can be made into good animal feedstuff. Mineral wastes can be recycled and reutilized. Wastes with certain heat value can be made into fuel for combustion. Through suitable treatment, harmful wastes can be used to make bricks. About wastes without any recycling value, our drying system can realize harmlessness and quantity reduction maximally.

With the development of economy and national environment protection awareness, waste disposal industry get developed rapidly. While industrialization procedure is getting faster and faster, sludge quantity grows also very fast. It becomes an urgent task to effectively solve sludge problem. Therefore, people pay more and more attention to treatment and utilization of sludge.

Taeda can provides various sludge drying machines which can used to deal with various sludge, like textile sludge, municipal sludge, paper making sludge, electroplating sludge, oil sludge, sewage sludge and etc.

No matter which kind of sludge you want to deal with, Taeda can always find you a suitable dryer to meet your demands in highest efficiency and least energy consumption.

Every kind of sludge drying machine produced by Zonelion Taeda are very easy to maintain and repair. All machines holds low malfunction rate. Customer can enjoy great pleasure for continuous production.

Taeda sludge drying systems are configured with complete exhaust gas disposal system like cyclone collector, scrubbing tower, pulse bag filter and etc, which makes whole system bring less emission to enviroment.

Our company can provide variuos drying equipment suitable for sludge drying, liike rotary dryer, rotary wing dryer and some customized drying systems.

|

WWTP sludge |

ETP sludge |

Sewage |

Drainage sludge |

Human feces |

Municipal sludge |

Paper making sludge |

|

Paper pulp sludge |

Coal sludge |

Coal slurry |

Textile sludge |

Animal manure |

Ore slurry |

Electroplating sludge |

|

Leather sludge |

Slaughter sludge |

Dehydration sludge |

Sludge cake |

Desulpurized gypsum |

Painting sludge |

Bio-sludge |

|

Deying sludge |

Pharmacy sludge |

Heavy me |

Oil sludge |

Clay |

Toxic sludge |

Pond sludge |

|

Organic sludge |

Inorganic sludge |

Chemical sludge |

Dewatered sludge |

Precipitation sludge |

Power plant sludge |

Alumina hydroxide filter cake |

|

Barium sulfate filter cake |

Blood serum |

Household wastes |

Spent grain |

Biogas residue |

Brewery grain |

Bean residues |

| Dryer Type | Heat source | Input moisture (%) | Final moisture (%) | Capacity |

| TDQ dryer | coal, diesel, natural gas, LPG, biomass pellets, hot air | 65%-85% | ≤15% | 0.6-15t/h |

| TDMED dryer | ≤15% | 0.5-20t/h | ||

| TDOSC | ≤10% | 0.5-7t/h | ||

| TDOSC-D dryer | 5%-15% | 1-40t/h | ||

| TDGD dryer | steam, hot oil | ≤15% | 50-900t/day | |

| KGX dryer | 5%-45% | 0.06-0.9t/h | ||

| CAO dryer | + alkaline | ≤30% | 50-150t/day | |

| WRC dryer | exhaust heat | ≈15% | 10-500t/day | |

| DW dryer | hot air, steam, electricity | 5%-45% | 0.6-1.5t/h |

General heat source

suitable for a variety of heat sources, not restricted by heat source

Low operating costs

Low energy consumption and low operating costs

Environmental protection

use various of dust collectors to meet local environmental standards

Quality control

High-precision process equipment, strict quality control

Support customization

customized equipment according to customer needs

Technical guidance

professional and technical personn-el on-site guidance operation

Automatic operation

automatic operation, simple operati-on and saving manpower