【Inupt moisture】:

【Output moisture】:

【Capacity】: 0.5-10t/h

【Application 】: Various sludge materials, like paper pulp sludge, textile sludge, municipal sludge, mineral slurry, coal sludge, ETP sludge WWTP sludge, gypsum, ore slurry, bentonite, spent grains, pomace, residue, pulp, filter cake.

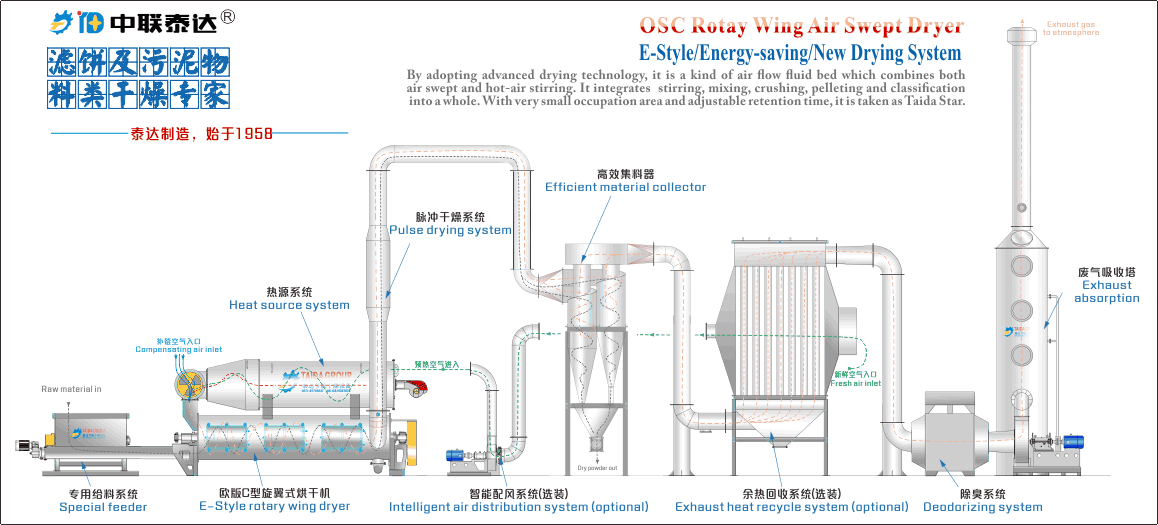

Taeda®E-style OSC air swept rotary wing dryer is also called E-style air swept dryer. It is fifth-generation new drying system developed by our company. OSC air swept dryer is designed mainly for drying high moisture viscous materials. It can be used to deal with materials with 95% moisture. In addition, OSC air swept dryer occupies very small area and holds wide application range. It integrates drying and grinding into one body. OSC air swept dryer can reach to appointed final moisture one time. Taeda company holds core independent intellectual property rights for whole set OSC air swept drying system.

Besides materials with 95% moisture content, OSC air swept dryer can also be used for drying pretty dry materials without relying on any feeding conditions. Air flow rate and material residence time can be controlled. Therefore, OSC air swept dryer support flash drying operation and batch calcining mode. Air swept dryer holds wide application range. It can be applied to dry pasty material, filter cake material, granule material and powder material. According exhaust temperature and product property, final moisture differ from 1% to 10%.

Taeda air swept dryer is fifth generation drying system developed by Taeda. With new design, length of first model is only 4m and capacity can reach 10m3/h. Evaporation ability can reach 300kg/h. It is featured in small footprint, large capacity, continuous operation and high mechanical level.

There is vortex generator, air damper, blocking ring, stirring blade and crushing hammer set on high speed rotary wing shaft. With scientific design, raw materials move smoothly in dryer. Wall sticking problem can be effectively avoided. Meanwhile, lumpy materials can be dispersed so that to improve drying efficiency.

Materials present boiling status inside air swept dryer under the function of vortex. Materials can fully contact with hot air and moisture can be evaporated fast. Both energy consumption and running cost are low. Customers can recover investment cost for drying equipment soon.

Whole drying system holds flexible configuration. We can configure hopper, feeder, heat source, conveying, dust collecting, product conveying and water scrubbing device. Professional team provides one-step service amd customizes suitable equipment ba

| Item | TDOSC310 | TDOSC510 | TDOSC1010 | TDOSC2010 | TDOSC3010 | TDOSC4010 | TDOSC5010 |

| Thermal value(10^4kCal/h) | 10 | 15 | 30 | 65 | 130 | 180 | 250 |

| Hot air(m3/h) | 2500 | 3720 | 7500 | 16000 | 32000 | 45000 | 70000 |

| Max evaporation(kg/h H2O) | 360 | 550 | 1100 | 2200 | 4500 | 5500 | 7800 |

| Power(kW) | 7.5 | 11 | 30 | 55 | 75 | 110 | 160 |

| L(mm) | 3800 | 4080 | 5200 | 5500 | 6500 | 10500 | 12000 |

| W(mm) | 1200 | 1500 | 2200 | 2900 | 3200 | 3800 | 4580 |

| H(mm) | 835 | 1000 | 1390 | 1800 | 2200 | 2680 | 3320 |