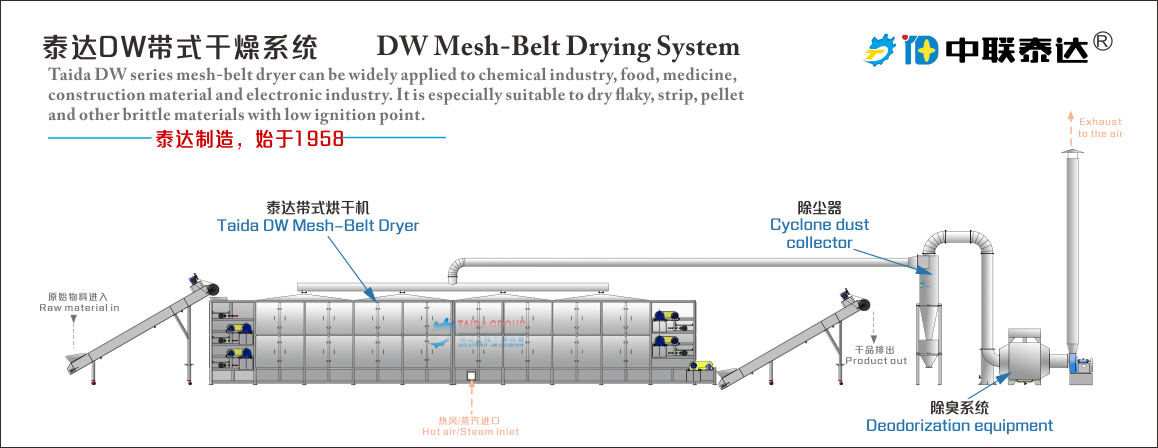

Taida DW series mesh-belt dryer can be widely applied to chemical industry, food, medicine, contruction material and electro industry. It is especilly suitable to dry slice, strip and pellet materials with good air permeability and breakable materials with low flash point. Aimed at different customers' demands, we can match corresponding crushing device, material distributing device and correcting device.

As for heat source system, there are various type availale, such as hot air, steam, electricity and etc.We can customize teflon mesh belt,wire mesh, stainless steel chain mesh and special steel belt in meet requirements of multiple raw materials. It is the professional deisgn team and rich technical experience that makes superior quality of DW series drying equipment. DW Series cannot only save energy, but also can maintain perfect inner and outer quality while achieving good drying effect.

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

|

Model |

DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-10 | DW-2-20 | |

| Unit no. | 4 | 5 | 4 | 5 | 4 | 5 | 10 | |

| Belt width (m) | 1.2 | 1.6 | 2 | |||||

| Drying stage length (m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 | |

| Material thickiness (mm) | 10-80 | |||||||

| Temperature (℃) | 50-140 | |||||||

| Steam pressure (Mpa) | 0.2-0.8 | |||||||

| Steam consumption (Kg/h) | 120-130 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | 450-1200 | |

| Drying period (h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.2-1.5 | 0.5-3 | |

| Drying capacity (Kg water/h) | 60-160 | 80-220 | 75-220 | 95-250 | 100-260 | 120-300 | 240-600 | |

| Installed power (kw) | 11.4 | 13.6 | 11.4 | 13.6 | 14.7 | 15.8 | 36.8 | |

|

Overall dimensions |

L m | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| W m | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 | |

| H m | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 | |

| Total weight (Kg) | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 | |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.