By adopting double-shaft mixing and screw propulsion, Our TDOCD-D rotary wing hot air mixing dryer is a kind of drying equipment which can finish ideal drying effect rapidly. It is especially suitable to dry viscous and high-moisture materials. It can dry materials with 65% moisture content to final 5% to 15% moisture one time. Its drying period is short, generally 2 to 50 minutes. Owing to fierce mixing of high-speed mixing blades, wet materials can contact fully with hot air under floating state. In the front part of dryer, evaporation speed of raw material is faster and the temperature of hot air in dryer drops down sharply. Therefore, even though using high-temperature hot air, temperature increase of raw materials is not very high.

Hot air mixing dryer is always used to dry typical high-moisture materials, such as: coal slime, coal slurry, various sludge, gypsum, ore slurry, bentonite, vinasse, pomace, medicine dregs, bean dregs, sugar residue, soya residue, peat and rare earth; organic materials, sludge compound materials and chemical raw materials, powder particle and flake high-moisture raw material.

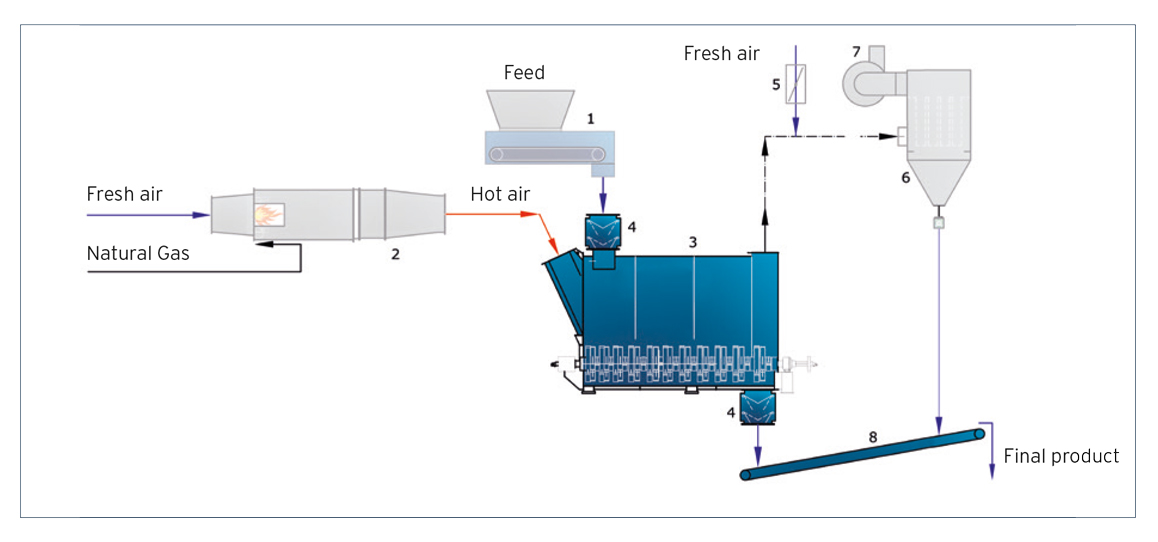

Working principle:

Double shaft hot air dryer adopts double-shaft mixing and screw propulsion to dry sticky and high-moisture materials. Hot air dryer can dry materials with 65% moisture to below 5% to 12% at one time. Drying period is very short, 2 to 20 minutes. Blades in hot air dryer can stir wet materials intensively, wet materials can contact fully with hot air. Moisture content of wet materials can be greatly evaporated faster in the former half part. Temperature of hot air in dryer drops sharply. Therefore, although hot air dryer applies hot air with high temperature, the temperature of raw materials will not increase greatly.

Owing to dispersion and agitation function,heat exchanging surface can be updated continuously. Therefore, heat transfer effect of the dryer is very strong.

There will be a concurrent flow between materials and airflow. Temperature of both materials and air can reach to a reasonable state. Drying time is very short, so pretty high drying temperature can be adopted.

Taida double-shaft hot air drying machine is characterized by Wide application, high output capacity, great moisture reduction, simple structure, small area occupation, less investment and maintenance cost.

Whole system is configured with advanced auxiliary machines and control system. With reasonble design, drying process can be finished stably and efficiently.

| Item | Unit | Model | ||||

| TDOSC-D1500 | TDOSC-D2500 | TDOSC-D3500 | TDOSC-D5500 | |||

| Moisture Reduced | kgH20/hr | 1500 | 2500 | 3500 | 5500 | |

| Maximum Flow of Wet Material | kg/h | 10000 | 15000 | 25000 | 40000 | |

| Maximum Moisture of Wet Material | % | 90 | 90 | 90 | 90 | |

| Output Moisture | % | 12-50 | 12-50 | 12-50 | 12-50 | |

| Installed power | Rotor Shaft Motor | kw | 22x2 | 22x2 | 30x2 | 45x2 |

| Scraper Shaft Motor | kw | 5.5 | 5.5 | 5.5 | 5.5 | |

| Back mixing motor | kw | 2.2 | 2.2 | 2.5 | 2.2 | |

| Temperature of Inlet Hot Air | ℃ | 350-800 | 350-800 | 350-800 | 350-800 | |

| Overall Dimension | mm | 4500x2100 | 5700x2100 | 6700x2100 | 7700x2100 | |

| x4000 | x4500 | x4500 | x4500 | |||

| Equipment Weight | kg | 10500 | 12000 | 18000 | 25000 | |