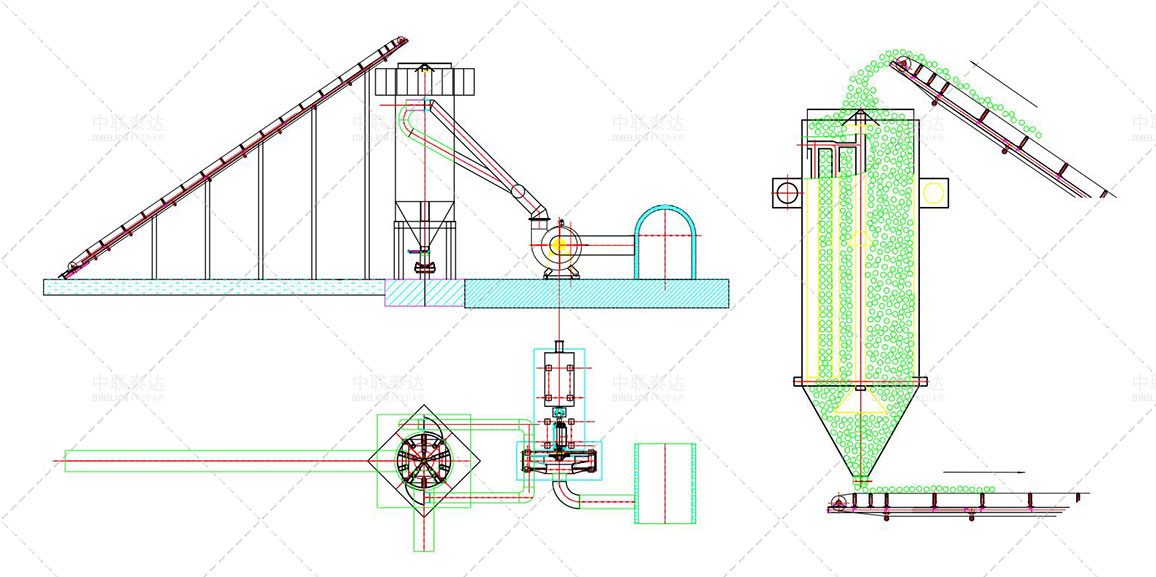

Vertical drying equipment is also called vertical dryer designed for coal and powdered ore cool suppression ball group's dehydration. Taeda vertical dryer is featured in reasonable design, high thermal utilization rate and good drying effect.

In terms of drying principle, vertical dryer belongs to a kind of corner-box structure moving bed dryer similar to grain drying tower. At begining of 21st century, Taeda combines cylinder structure and corn-box principle together first, which breaks through limit of square tower structure and helps finalization of vertical dryer series. During real working situation, Taeda vertical dryer holds higher capacity and causes less material crushing rate. Materials can turn and roate evenly in vertical dryer. Followinglyl, vertical dryer appears as common drying system gradually in market. Thanks to less investment cost, short fabrication period and low running cost, Taeda vertical dryer is widely applied for drying various ball briquettes and pellets. Moisture reduction of Taeda vertical dryer ranges from 5% to 15%. Taking coal briquettes produced by briquetting machine, moisture of ball briquettes produced from better briquetting machine and better formula always ranges from 8% to 12%. After being dried by vertical dryer, final moisture can be reduced to 1% to 4%.

Taeda vertical dryer is fully embodied with Taeda designing concept like easy operation, innovation, high efficiency, low energy consumption, low cost, good quality, safe production and less pollution. During years continuous upgrading, feeding and discharging device are improved. Dust collecting system is also designed with new configuration so that to guarantee green production.

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Name Model | 2200 | 2600 | 2800 | ||

| WLLG vertical drying equipment | Dry quantity(t/h) | 3-5 | 6-8 | 8-10 | 10-14 |

| Dry time(h) | 2-2.5 | 2-2.5 | 2-2.5 | 2-2.5 | |

| Moisture content of feeding material (%) | 8-12 | 8-12 | 8-12 | 8-12 | |

| Moisture content of discharging material (%) | 1.5-3 | 1.5-3 | 1.5-3 | 1.5-3 | |

| Need power(KW) | 18.5 | 22 | 37 | 45 | |

| Coal consumption of hot blast stove(kg/h) | ≥100 | ≥150 | ≥180 | ≥230 | |

| Temperature range(°C) | 200-260 | 200-260 | 200-260 | 200-260 | |

| Operator | 2 people/turn | 2 people/turn | 2 people/turn | 2 people/turn | |

| Remarks | Coal caloric value is more than 5000 calories | ||||

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.