Established in 1958, TAIDA Drying Equipment Co., Ltd is a professional manufacturer of spray granulation dryer in China. Besides spray granulation dryer, we also provide customers worldwide with rotary dryer, rotary cooler, cement production line, cement grinding plant, industrial kiln and furnace, grinding equipment, crushing equipment, environmental protection equipment, cooling equipment, drying equipment, compound fertilizer equipment, packing machine, chemical equipment and electrical control system. With the certification of ISO9000 and CE, our products have been well received by customers from as many as 60 countries and districts such as Germany, Russia, Brazil, Egypt, Iran, Japan, South Korea, Bengal, Pakistan, Turkey, Burma, Vietnam, South Africa, Columbia, Bolivia, etc. If you're interested in our spray granulation dryer, please contact us freely.

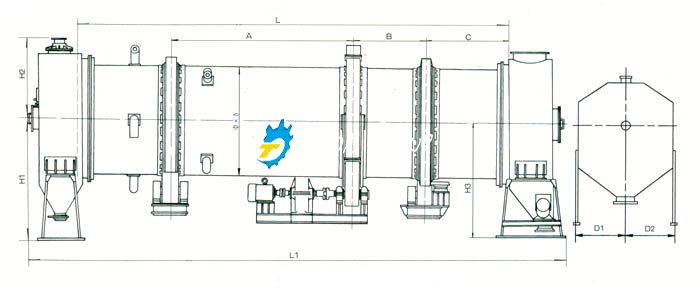

This PZ type spray granulation dryer has integrated the spraying, granulating, and drying into one body. A series of new technologies have been used in the process of its manufacture, such as strengthened bricks, heat transfer, internal classification, internal material returning, internal crushing, and so on. It has features of high productivity, easy operation, energy saving, simple process flow, etc.

When the temperature is too high, there will no oxide skin. This machine is characterized by good abrasive resistance. Therefore, it has a long service span.

There are various inlet temperatures. This machine can make the materials at outlet presented as small particles or powder which provides convenience for next process.

There is a whole set of equipment which holds 10 to 200t/h output capacity. We can also customize drying machine according to customer’s demands.

Reasonable design can avoid the leakage of materials.It adopts special seal structure made from tin steel piece between cover body and machine, which prevents leakage under micro negative pressure.

| Specification | Output (t/h) | Rotating speed of cylinder(r/min) | Cylinder slope (%) | Inlet temperature | Slurry temperature | Moisture of slurry | Motor power (kw) | Weight (t) |

| Φ3.0×12 | 100-150 | 5.0 | 1.76 | 350℃ | 110℃ | 25-30% | 55 | 71.0 |

| Φ3.0×13 | 100-150 | 5.0 | 1.76 | 350℃ | 110℃ | 25-30% | 55 | 75.3 |

| Φ4.0×12 | 150-200 | 4.1 | 1.5 | 350℃ | 110℃ | 25-30% | 110 | 105 |

| Φ4.0×14 | 150-200 | 4.1 | 1.5 | 350℃ | 110℃ | 25-30% | 130 | 109.8 |

| Φ3.0×12 | 200-300 | 4.1 | 1.5 | 450℃ | 110℃ | 25-30% | 160 | 151 |

| Φ3.0×12 | 200-300 | 4.1 | 1.5 | 450℃ | 110℃ | 25-30% | 185 | 160 |

| Φ3.0×12 | 400-500 | 4.1 | 1.5 | 450℃ | 110℃ | 25-30% | 220 | 184 |

| Φ3.0×12 | 400-500 | 4.1 | 1.5 | 450℃ | 110℃ | 25-30% | 250 | 196 |

| Φ3.0×12 | 500-600 | 4.1 | 1.5 | 650℃ | 115℃ | 25-30% | 280 | 255 |

| Φ3.0×12 | 500-600 | 4.1 | 1.5 | 650℃ | 115℃ | 25-30% | 315 | 265 |