Aluminum hydroxide is most widely used inorganic flame retardant additive. As a flame retardant, aluminum hydroxide can not only retard flame , but also can prevent production of smoke, drips, and toxic gases. Therefore, aluminum hydroxide has been widely applied and its usage is increasing year by year. Aluminum hydroxide is widely applied in industries like thermosetting plastics, thermoplastics, synthetic rubber, coatings and building materials.

For aluminum hydroxide, Taeda aluminum hydroxide dryer is a kind of popular drying equipment in relevant industry. Taeda aluminum hydroxide dryer is developed based on traditional rotary drum dryer. Aimed at features of aluminum hydroxide material and combining with our own experience, we developes the new generation aluminum hydroxide dryer. At present, Taeda aluminum hydroxide dryer has been widely put into market and enjoys great popularity among customers.

New Design Guarantees Small Footprint And Good Drying Effect

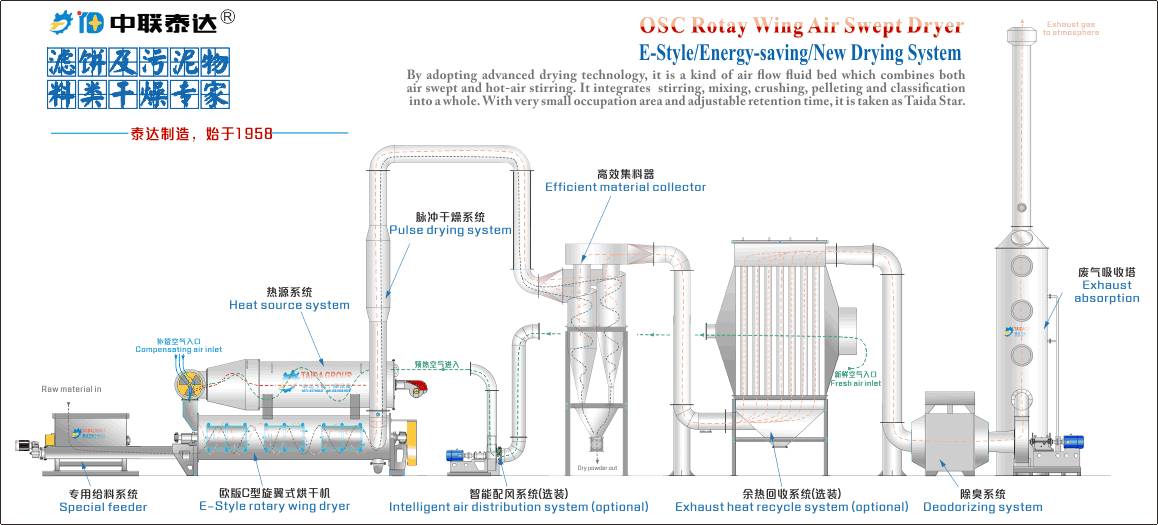

Aluminum hydroxide filter cake air swept dryer is Taeda fifth generation drying system which holds good drying effect for aluminum hydroxide filter cake,powder material. Its occupation area is only one third of common dryer. As a kind of continuous drying system, it holds great drying effect.

Scientific Structure And Easy Operation

There is vortex generator, air damper, blocking ring, stirring blade and crushing hammer set on high speed rotary wing shaft. With scientific design, raw materials move smoothly in dryer. Wall sticking problem can be effectively avoided. Meanwhile, wet micro powder and filter cake can be evenly dried into dry powder so that to improve drying efficiency.

Low Energy Consumption and Cheap Running Cost

Materials present boiling status inside air swept dryer under the function of vortex. Materials can fully contact with hot air and moisture can be evaporated fast. Both energy consumption and running cost are low. Customers can recover investment cost for drying equipment soon.

More Flexible Configuration and Low Exhaust Emission

Whole drying system holds flexible configuration. We can configure hopper, feeder, heat source, conveying, dust collecting, product conveying and water scrubbing device. Professional team provides one-step service amd customizes suitable equipment ba

| Item | TDOSC310 | TDOSC510 | TDOSC1010 | TDOSC2010 | TDOSC3010 | TDOSC4010 | TDOSC5010 |

| Thermal value(10^4kCal/h) | 10 | 15 | 30 | 65 | 130 | 180 | 250 |

| Hot air(m3/h) | 2500 | 3720 | 7500 | 16000 | 32000 | 45000 | 70000 |

| Max evaporation(kg/h H2O) | 360 | 550 | 1100 | 2200 | 4500 | 5500 | 7800 |

| Power(kW) | 7.5 | 11 | 30 | 55 | 75 | 110 | 160 |

| L(mm) | 3800 | 4080 | 5200 | 5500 | 6500 | 10500 | 12000 |

| W(mm) | 1200 | 1500 | 2200 | 2900 | 3200 | 3800 | 4580 |

| H(mm) | 835 | 1000 | 1390 | 1800 | 2200 | 2680 | 3320 |