【Inupt moisture】:

【Output moisture】:

【Capacity】: 0.3-15t/h

【Applicable material】: Suitable for drying blood plasma protein, sludge, gypsum, ore slurry, bentonite, spent grains, pomace, herb residue, bean pulp, soybean meal, sugar residue, soya residue, coal peat, rare earth and other high moisture materials, plastic, organic materials, Aluminium hydroxide, Calcium hydroxid, inorganic compounds, slurry/powder/granule/flake high moisture materials.

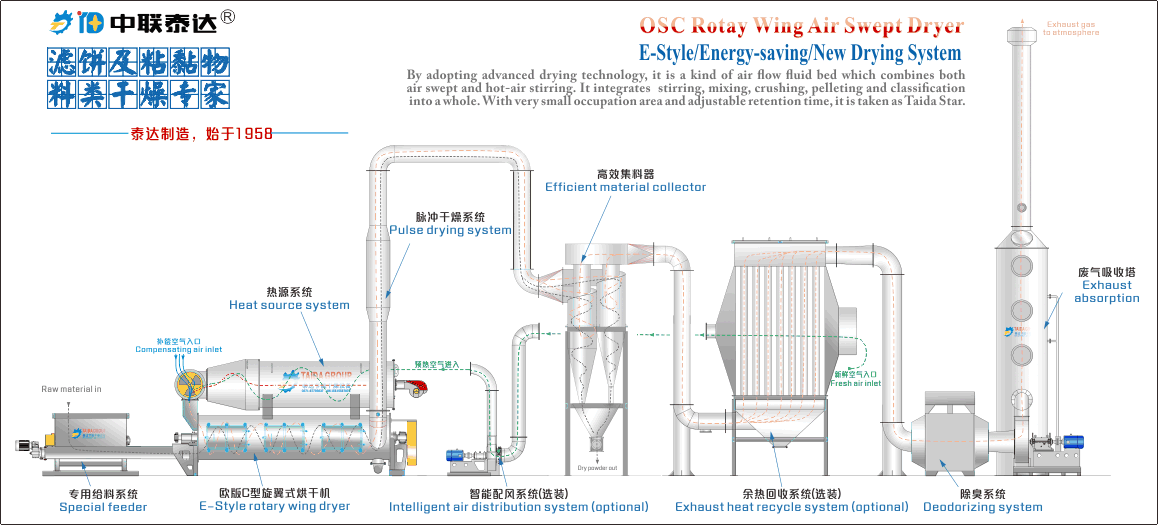

OSC air swept rotary wing dryer is fifth generation drying machine developed by our company. It is especially designed for high-moisture viscous paste materials. It can be used to deal with materials with 95% moisture. With less area occupation, it holds wide application range. As a drying machine which integrates drying and crushing into a whole, it can reduce materials’ moisture to standard level.

Typical materials suitable for Air Swept Rotary Wing Dryer:

This series drying equipment can be used to dry various raw materials like aluminum hydroxide, bentonite, bone meal, spent grain, calcium carbonate, cellulose, ceramic fiber, grain, animal manure, pomace, animal protein, municipal wastes, sludge and other materials with certain moisture and particle size from beneficiation, Aluminium hydroxide, Calcium hydroxid, construction material, chemical industry and feedstuff industries.

OSC Series Rotary Wing Dryer adopts the most advanced drying technology. It can almost deal with any kinds of materials, from low-solid contents to low-moisture powder. Materials’ routine in dryer can be easily controlled. Therefore, this drying system can be used to produce dry fine powder and moist granular materials. There are three separate zones set in the drying system. Central retention zone decides the residual moisture and physical size of final products. Although this drying system adopts high temperature difference, but same with majority instant dryers, products’ temperature is lower than wet ball humidity. Heat source of this dryer can adopt oil-fired or gas-fired hot air fan. Generally speaking, heat source device is always integrated with drying cylinder. Products can enter terminal region directly from drying tubes. Final products can be collected by separator and bag filter. This series of dryer contains 9 sizes. Evaporation speed can reach as high as 8ton per hour.

More information you may be interested in:

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Item | TDOSC310 | TDOSC510 | TDOSC1010 | TDOSC2010 | TDOSC3010 | TDOSC4010 | TDOSC5010 |

| Thermal value(10^4kCal/h) | 10 | 15 | 30 | 65 | 130 | 180 | 250 |

| Hot air(m3/h) | 2500 | 3720 | 7500 | 16000 | 32000 | 45000 | 70000 |

| Max evaporation(kg/h H2O) | 360 | 550 | 1100 | 2200 | 4500 | 5500 | 7800 |

| Power(kW) | 7.5 | 11 | 30 | 55 | 75 | 110 | 160 |

| L(mm) | 3800 | 4080 | 5200 | 5500 | 6500 | 10500 | 12000 |

| W(mm) | 1200 | 1500 | 2200 | 2900 | 3200 | 3800 | 4580 |

| H(mm) | 835 | 1000 | 1390 | 1800 | 2200 | 2680 | 3320 |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.