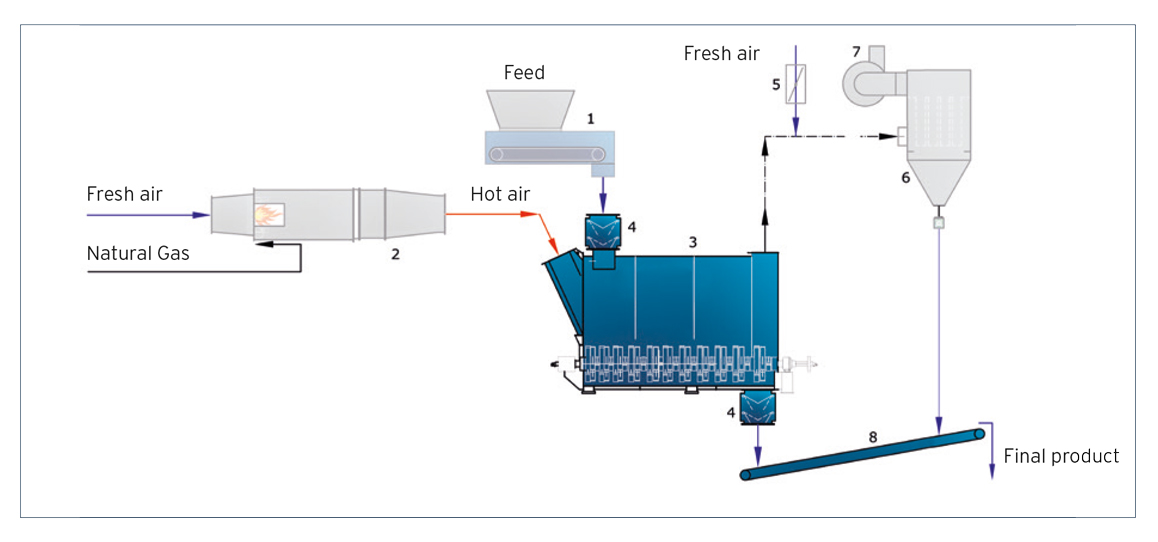

TDOSC-D model rotary wing dryer is also called WJG hot air stirring dryer which is a kind of drying equipment can finish ideal drying effect rapidly. By adopting double-shaft mixing and screw propulsion, Our TDOSC-D rotary wing hot air mixing dryer is a kind of It is especially suitable to dry viscous and high-moisture materials. It can dry materials with 65% moisture content to final 5% to 15% moisture one time. Its drying period is short, generally 2 to 50 minutes. Owing to fierce mixing of high-speed mixing blades, wet materials can contact fully with hot air under floating state. In the front part of dryer, evaporation speed of raw material is faster and the temperature of hot air in dryer drops down sharply. Therefore, even though using high-temperature hot air, temperature increase of raw materials is not very high.

Hot air stirring dryer is always used to dry typical high-moisture materials, such as: coal slime, coal slurry, various sludge, gypsum, ore slurry, bentonite, vinasse, pomace, medicine dregs, bean dregs, sugar residue, soya residue, peat and rare earth; organic materials, sludge compound materials and chemical raw materials, powder particle and flake high-moisture raw material.

Double shaft hot air dryer adopts double-shaft mixing and screw propulsion to dry sticky and high-moisture materials. Hot air dryer can dry materials with 65% moisture to below 5% to 12% at one time. Drying period is very short, 2 to 20 minutes. Blades in hot air dryer can stir wet materials intensively, wet materials can contact fully with hot air. Moisture content of wet materials can be greatly evaporated faster in the former half part. Temperature of hot air in dryer drops sharply. Therefore, although hot air dryer applies hot air with high temperature, the temperature of raw materials will not increase greatly.

More information you may be interested in:

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Item | Unit | Model | ||||

| TDOSC-D1500 | TDOSC-D2500 | TDOSC-D3500 | TDOSC-D5500 | |||

| Moisture Reduced | kgH20/hr | 1500 | 2500 | 3500 | 5500 | |

| Maximum Flow of Wet Material | kg/h | 10000 | 15000 | 25000 | 40000 | |

| Maximum Moisture of Wet Material | % | 90 | 90 | 90 | 90 | |

| Output Moisture | % | 12-50 | 12-50 | 12-50 | 12-50 | |

| Installed Capacity | Rotor Shaft Motor | kw | 22x2 | 22x2 | 30x2 | 45x2 |

| Scraper Shaft Motor | kw | 5.5 | 5.5 | 5.5 | 5.5 | |

| Back mixing motor | kw | 2.2 | 2.2 | 2.5 | 2.2 | |

| Temperature of Inlet Hot Air | ℃ | 350-800 | 350-800 | 350-800 | 350-800 | |

| Overall Dimension | mm |

4500x2100 x4000 |

5700x2100 x4500 |

6700x2100 x4500 |

7700x2100 x4500 |

|

| Equipment Weight | kg | 10500 | 12000 | 18000 | 25000 | |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.