【Heat source】: Flue gas, electric heating, natural gas, diesel oil, heavy oil, coal, bio-pellet fuel

【Raw materials】: Sand stone, ore powder, mineral slag, sludge, animal manure, worese slag, wood, plastics and metal, etc

【Diameter】: φ0.3-φ6.0m

【Capacity】: 1-150t/h

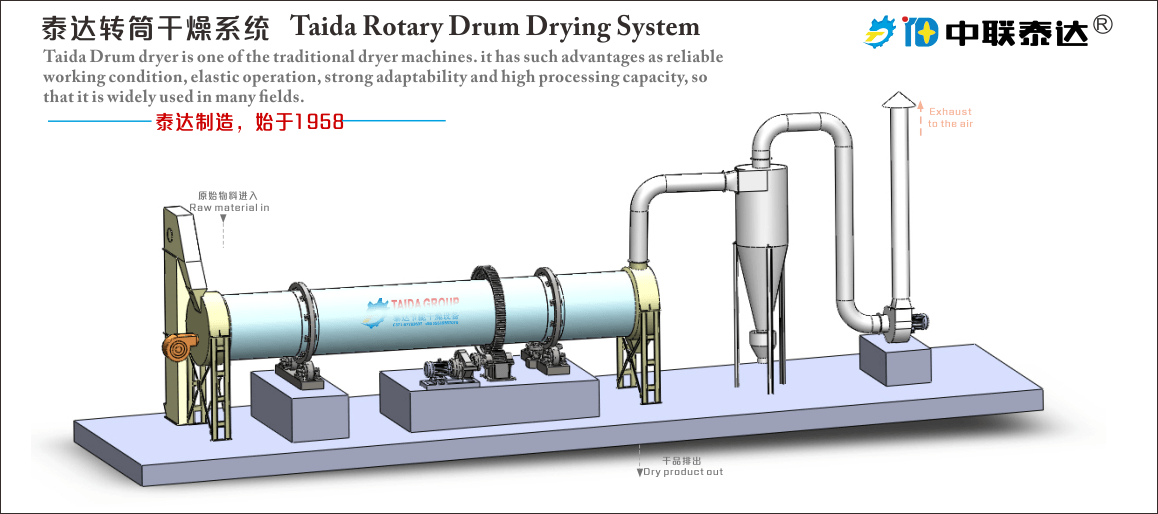

Rotary drum dryer is also called rotary kiln dryer or rotar dryer. It makes use of hot air to realize drying aim. In terms of material flowing mode, rotary dryer belongs to mobile bed dryer. Materials directly contact with hot air in rotary drum. Under function of elevation and lifting plates combination structure, there will be reasonable material curtain formed. During heat exchanging process, moisture in material can be evaporated. During installation process, rotary dryer drum will be placed obliquely. Under the function of drum rotation and slope, materials slowly move to discharging end from feeding part. After temperature increasing, drying, cooling and discharging procedures, qualifed dry products will flow out from discharging port. In order to control the drying temperature, thermocouple is disposed on feeding and discharging device . It can display the temperature on feeding /end site by thermometer ,providing basis for controlling cylinder temperature (350-380 degrees).

Through years upgrading and improvement, Taeda has developed series rotary drum dryer like MGT rotary dryer and MED rotary dryer. Reasonable feeding/discharging structure and material lifting structure can make material in dryer scattered uniformly and thin material curtain will be formed. Materials can fully contact with hot air flow to achieve full utilization of the heat energy. Reasonable selection parameters of drying machine makes that coal consumption and electricity consumption is less 10-15% than common drier at least and yield is increased by 10-15%. Taeda rotary drum dryer has been widely used in cement and mineral processing enterprises.

Our rotary dryer is one of the traditional drying equipments and suitable for drying mineral materials, metal materials, chemical materials, wood, and various weak-viscous carbon based/silicon based materials, etc

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Type (mm) | Indiclination (%) | rotation speed (r/min) | input tempreture (℃) | motor power (kw) | Output (t/h) |

| Φ600×6000 | 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 |

| Φ800×8000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.0 |

| Φ800×10000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 |

| Φ1000×10000 | 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 |

| Φ1200×10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 |

| Φ1200×12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 |

| Φ1500×12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 |

| Φ1800×12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 |

| Φ1800×18000 | 3-5 | 2-6 | ≤800 | 18.5 | 6-13 |

| Φ2200×12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 8-15 |

| Φ2200×18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 |

| Φ2200×20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 |

| Φ2400×20000 | 3-5 | 1.5-5 | ≤800 | 37 | 18-30 |

| Φ3000×20000 | 3-5 | 1.5-5 | ≤800 | 55 | 25-35 |

| Φ3000×25000 | 3-5 | 1.5-5 | ≤800 | 75 | 32-40 |

| Note | Our limit is 6.0m in diameter, but easily transportable models are usually < 3.2m. If you need a large rotary dryer, please contact us | ||||

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.