Capacity: 0.2-25t/h

Motor power:3-22kw

Inlet& outlet temperature: 150-250℃→60℃

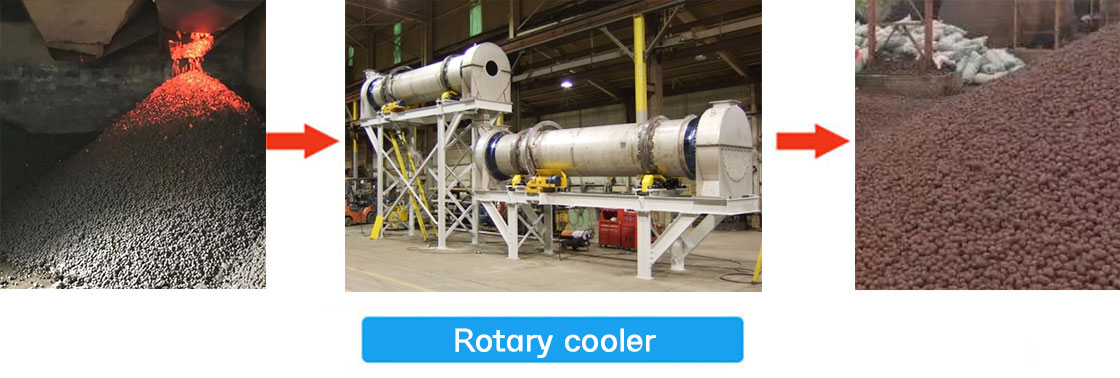

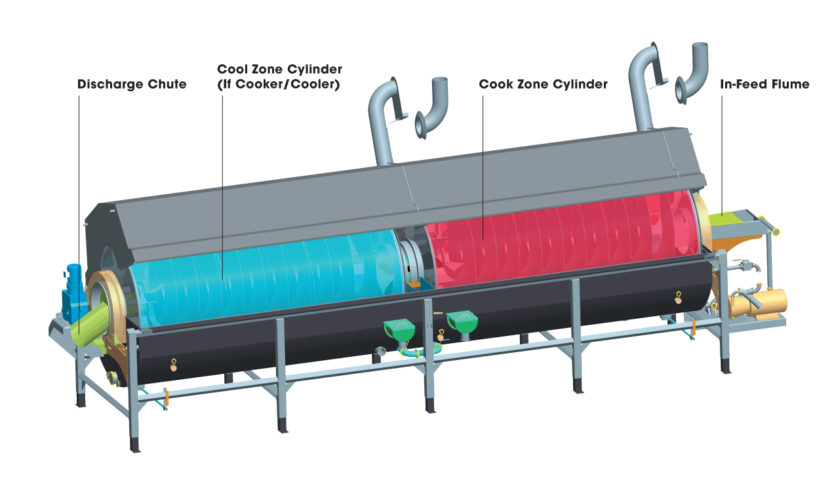

Material after drying or calcination have high temperature and shall be cooled to prevent caking. Rotary drum cooling machine is used to cool material with certain temperature and particle size in whole production line. The cooler is used combining with the rotary dryer/rotary kiln which can greatly increase the cooling rate, reduce labor intensity, increase capacity, and further remove the moisture and reduce the temperature of product. Besides, rotary drum cooler can also be used for cooling other powdery or granular material. Generally, the feed temperature is 150-250℃, and the discharge temperature is less than 40℃.

The working principle of rotary cooler machine is through the air flow and counter-flow reverse. By the suction of induced draft fan make internal air flow accelerated, the lifting board make the material go up and down. So the material fully contacts with the cold air and then achieve the goal of cooling.

Compact structure, easy maintenance, reliable performance, low energy consumption.

There are various inlet temperatures. This machine can make the materials at outlet presented <60℃ which provides convenience for next process.

There is a whole set of equipment which holds 10 to 200t/h output capacity. We can also customize cooling machine according to customer’s demands.

Reasonable design can avoid the leakage of materials.It adopts special seal structure made from tin steel piece between cover body and machine, which prevents leakage under micro negative pressure.

| Model |

Diameter (mm) |

Length (mm) |

Dip angle (°) |

Rotation speed (r/min) |

Capacity(ton/hr) |

Inlet temperature (℃) |

Outlet temperature (℃) |

Power (kw) |

| TDLQ0608 | 600 | 8000 | 3 | 5 | 0.2-0.6 | 150-250 | 60~80 | 3 |

| TDLQ0808 | 800 | 8000 | 3 | 5 | 1-1.5 | 150-250 | 60-80 | 4 |

| TDLQ1010 | 1000 | 10000 | 3 | 5 | 1.5-2.5 | 150-250 | 60-80 | 5.5 |

| TDLQ1212 | 1200 | 12000 | 3 | 5 | 2.5-5 | 150-250 | 60-80 | 7.5 |

| TDLQ1515 | 1500 | 15000 | 3 | 5 | 3-10 | 150-250 | 60-80 | 11 |

| TDLQ1616 | 1600 | 16000 | 3 | 5 | 6-18 | 150-250 | 60-80 | 18.5 |

| TDLQ1818 | 1800 | 18000 | 3 | 5 | 11-20 | 150-250 | 60-80 | 18.5 |

| TDLQ2020 | 2000 | 20000 | 3 | 4 | 15-25 | 150-250 | 60-80 | 22 |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.