【Capacity】:

【Power】: 32-165Kw

【Initial moisture】: 70-80%

【Applicable material】: Various animal blood like pig blood, chicken blood, Duck blood, recycled animal blood from slaughtering house, cooked blood curd and un-bolier animal blood curd.

As a major ingredient of plasma, blood plasma protein accounts for 60% to 80% of plasma. There are various kinds of plasma protein and their functions are not same. Animal protein industry is developing very fast at home. Animal plasma protein is applied for animal feed as feed additive. But, the application of plasma protein for food is not so wide. Pig blood contains rich protein and it is always called liquid meat. Pig and animal blood deep processing holds great development prospect. Plasma protein is frequently used in feedstuff industry. In recently years, blood plasma protein is gradually growing well in food aspect.

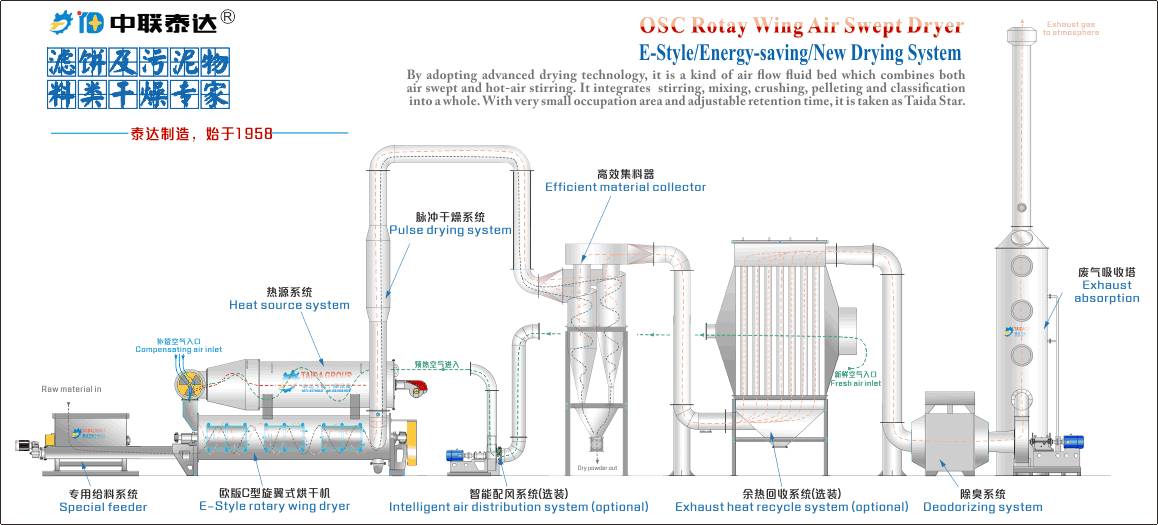

Taeda air swept rotary wing drum dryer is specially designed for high moisture and sticky materials. It is characterized by small occupation area, large capacity, good drying effect and high drying efficiency. After drying by air swept drum dryer, final moisture of animal blood can be as low as 10% one time.

More information you may be interested in:

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Item | TDOSC310 | TDOSC510 | TDOSC1010 | TDOSC2010 | TDOSC3010 | TDOSC4010 | TDOSC5010 |

| Thermal value(10^4kCal/h) | 10 | 15 | 30 | 65 | 130 | 180 | 250 |

| Hot air(m3/h) | 2500 | 3720 | 7500 | 16000 | 32000 | 45000 | 70000 |

| Max evaporation(kg/h H2O) | 360 | 550 | 1100 | 2200 | 4500 | 5500 | 7800 |

| Power(kW) | 7.5 | 11 | 30 | 55 | 75 | 110 | 160 |

| L(mm) | 3800 | 4080 | 5200 | 5500 | 6500 | 10500 | 12000 |

| W(mm) | 1200 | 1500 | 2200 | 2900 | 3200 | 3800 | 4580 |

| H(mm) | 835 | 1000 | 1390 | 1800 | 2200 | 2680 | 3320 |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.