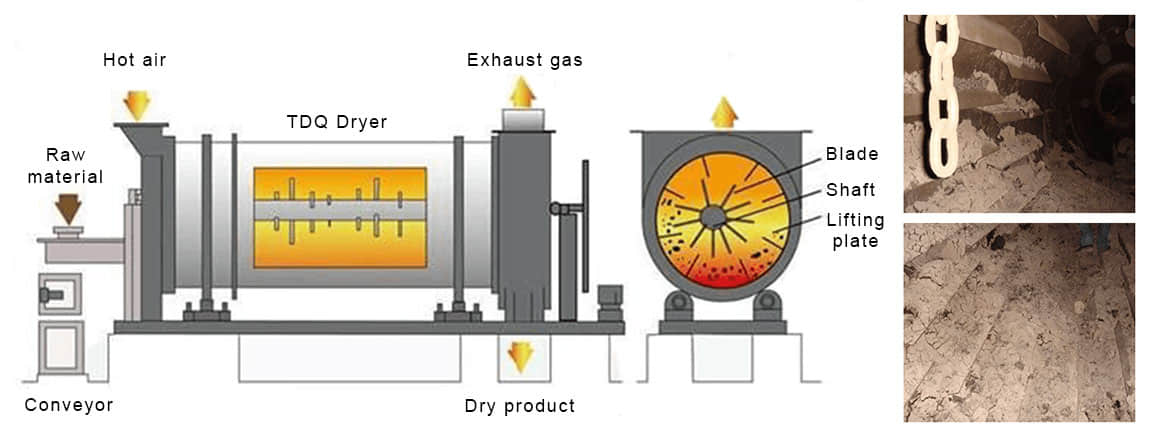

Taeda TDQ dispersing/Smashing drum dryer is a kind of new and efficient drying machine developed based on absorbing foreign drying technologies. It also combines features and performances of rotary kiln dryer. TDQ dryer occupies less footprint. There is dispersing/shattering shaft installed in drum and it is also called dispersing/shattering type rotary drum dryer. All these features make TDQ dryer suitable for drying pomace, biomass residue, manure and sludge materials.

TDQ dispersing/smashing dryer is a kind of dryer with high mechanical level. Both flow resistance to dryer and energy consumption are less. Aimed at features of pomace and manure sludge materials, dispersing crushing blades in drum can effectively avoid lumping. Thus, drying process can be done smoothly. After drying, dried pomace products can be used for feedstuff, combustion and fertilizer industries. Dried manure sludge materials can be used as fuel and provide heat for other industries. TDQ dryer makes it possible to make wastes into useful resources.

In addition, TDQ dryer can also match with low temperature exhaust gas and make use of 150℃ flue gas to quickly dry large amount of sludge and pomace materials. During designing, Taeda company fully takes features of pomace and manure sludge material into consideration and provides reasonable configuration so that each TDQ drying system can reach to best drying effect.

More information you may be interested in:

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Specifications | TDQ-Ⅰ | TDQ-Ⅱ | TDQ-Ⅲ | TDQ-Ⅳ | TDQ-Ⅴ |

| Capacity (T/D) | 5-8 | 18-30 | 35-55 | 75-90 | 95-115 |

| Input capacity (T/H) | 0.6-1 | 3.4-3.5 | 5.5-7.5 | 9.5-12.5 | 12.5-15 |

| Installed power (Kw) | 9.5 | 13 | 18.5 | 33.5 | 37 |

| Occupation area (m2) | 25 | 35 | 45 | 80 | 100 |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.