Capacity: 20-300t/h

Motor power:7.5-37×2kw

Inlet size(mm): 10-75mm

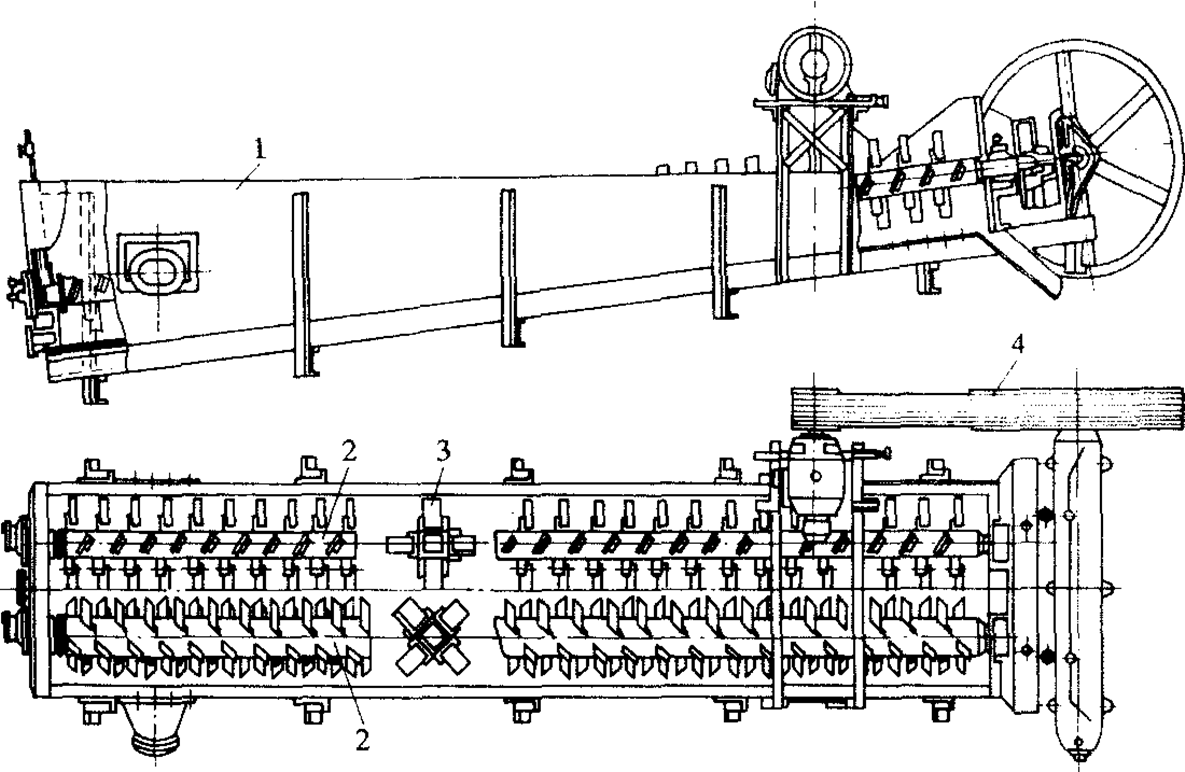

Stone washer is also called ore washer. Sedimentation speed of particles with different gravity differ. By taking advantage of that principle, stone washer realizes the mechanical classification aim. Dust and impurities will be separated owing to buoyant effect.

Taida XL series stone washer is characterized by long screw body, good seal performance, simple structure, high output capacity, easy maintenance and low output sand/water moisture content. At present, Taida screw washing equipment has been widely applied to wash dressing, classification and debris cleaning work in highway, railway, metallurgy, construction materials and hydropower industry. Medium and light models in this series is suitable for washing classifying work of fine particle materials. Heavy model is suitable for washing classifying work of coarse particle materials.

The operation parameters is under automatic control to ensure the best running condition;

With reasonble structure, Taida washer consumes less elecricity and holds high output capacity.

Taida stone washing equipment can be applied to mining, me

By adopting superior abrasion-resistant texture, Taida washing equipment holds longer operation than common washing machines.

| Type | No. | Specifications |

Screw diameter (mm) |

Inlet size(mm) |

Water consumption (m3/h) |

Capacity (t/h) |

Power (kw) |

Overall dimensions(mm) |

Weight (kg) |

| Light single screw | 1 | XL-508 | 508 | <10 | 6~60 | 20 | 7.5 | 8000×2343×1530 | 2670 |

| 2 | XL-610 | 610 | <10 | 6~63 | 50 | 7.5 | 8000×2490×1530 | 3800 | |

| 3 | XL-762 | 762 | <10 | 9~63 | 75 | 11~15 | 9070×2650×1530 | 5225 | |

| 4 | XL-914 | 914 | <10 | 10~80 | 100 | 11~15 | 9070×2650×1638 | 6370 | |

| 5 | XL-1118 | 1118 | <10 | 13~168 | 175 | 30 | 9070×2830×1900 | 9800 | |

| Light double screw | 1 | 2XL-762 | 762 | <10 | 20~150 | 140 | 2×11 | 11580×3965×2370 | 7440 |

| 2 | 2XL-914 | 914 | <10 | 50~300 | 200 | 2×15 | 9070×3500×1638 | 9531 | |

| 3 | 2XL-1118 | 1118 | <10 | 60~600 | 350 | 2×22 | 9070×3890×1900 | 16700 | |

| Heavy single screw | 1 | XLZ-762 | 762 | <60 | 160~220 | 80~125 | 22 | 11580×5226×2370 | 9800 |

| 2 | XLZ-914 | 914 | <60 | 200~300 | 125~175 | 30 | 6980×1200×1340 | 11800 | |

| 3 | XLZ-1118 | 1118 | <75 | 250~350 | 180~250 | 37 | 7400×1380×1950 | 13955 | |

| Heavy double screw | 1 | 2XLZ-762 | 762 | <60 | 300~400 | 100~150 | 2×22 | 6980×2091×1340 | 16800 |

| 2 | 2XLZ-914 | 914 | <60 | 350~450 | 150~200 | 2×30 | 7120×2146×1590 | 20800 | |

| 3 | 2XLZ-1118 | 1118 | <75 | 450~550 | 200~300 | 2×37 | 8500×2861×2150 | 23870 |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.