【Lowest moisture】:

【Capacity】: 0.2-12tph

【Application range】: Wdely applied in pasture, farm, feedstuff factory and grass powder pellet industry.

Taeda forage grass mesh belt dryer is a kind of multiple layer belt dryer specially designed for forage grass materials ( foxtail grass, buckwheat, rye grass, elephant grass, mulberry protein and other pastures, leaf and stalk pastures, silage (corn, sweet potato, forage grass, vegetables, leaves, sunflower stalks, Jerusalem artichoke stalks and other silages). Thickness of material layer is 1-8cm and drying work is efficient. As a kind of continuous running dryer, it is regarded as high-end forage grass drying equpment. In terms of structure, it can be regarded as a dryer which makes use of steel mesh or teflon mesh as conveying belt to continuously transfer materials. Therefore, Taeda forage grass dryer is suitable for assembly line work. Because conveying belt is a kind of mesh structure, it is also a kind of ideal drying equipment for drying food and vegetables. This mesh belt dryer can match with other devices or work separately. Customers can make rational option based on real situation.

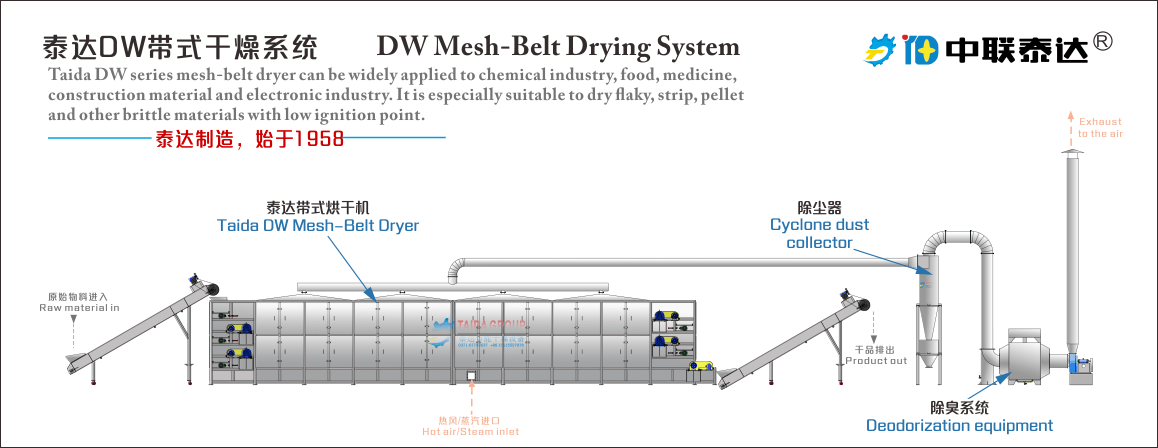

Working principle of forage grass mesh belt dryer:As a kind of continuous production drying equipment, Taeda forage grass dryer. Fresh forage grass is evenly scattered on mesh belt and move back and forward under the driving of drying belt. Hot air will pass through middle of raw materials. Vapor will be discharged out from dehumidification hole. Hot air will circulate in drying chamber and moisture will be discharged to air through fan. Then, drying work is finished.

Design of Taeda forage grass mesh belt dryer fully takes features of forage grass materials into consideration such as irregular dimension, high moisture content, light bulk density, with stem stalk and easy color changing. Taeda mesh belt dryer guarantees good final quality and color.

Because Taeda forage grass mesh belt dryer is designed for forage grass material drying. Materials layer on mesh belt is thicker than common belt dryer. Hot air utilization is efficiency in unit are and drying ability is strong. Aimed at light forage grass material, speed and structure of mesh belt adopt special design, which make Taeda mesh belt dryer durable, stable and mechanical.

Besides common various heat source like coal furnace, gas or oil firing hot air furnace, Taeda forage grass mesh belt dryer can also dock with heat pump and steam heating modular. Air duct and heat radiator of Taeda mesh belt dryer are arranged in reasonble mode. Correspondingly, its energy utilization rate is higher and loss rate is low. Energy conservation performance is more obvious than common dryer.

Whole mesh belt dryer is divided into multiple chambers. It can be put into use after easy combination and assembly once arrival at working place. It can be used as a individual production line. In order to enlarge capacity and improve working efficiency, mesh belt dryer can also be installed in serial or in parallel modes. Taeda professional team provides you complete tailor made services on plan solution, installation and training.

| Model | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-10 | DW-2-20 | |

| Unit no. | 4 | 5 | 4 | 5 | 4 | 5 | 10 | |

| Belt width (m) | 1.2 | 1.6 | 2 | |||||

| Drying stage length (m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 | |

| Material thickiness (mm) | 10-80 | |||||||

| Temperature (℃) | 50-140 | |||||||

| Steam pressure (Mpa) | 0.2-0.8 | |||||||

| Steam consumption (Kg/h) | 120-130 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | 450-1200 | |

| Drying period (h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.2-1.5 | 0.5-3 | |

| Drying capacity (Kg water/h) | 60-160 | 80-220 | 75-220 | 95-250 | 100-260 | 120-300 | 240-600 | |

| Installed power (kw) | 11.4 | 13.6 | 11.4 | 13.6 | 14.7 | 15.8 | 36.8 | |

|

Overall dimensions |

L m | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| W m | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 | |

| H m | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 | |

| Total weight (Kg) | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 | |