CAO Series drying system is set of stable sludge drying system specially designed for large-medium sized and small sized waste water treatment plants to deal with sludge. It reaches moisture reduction aim by adding calcium or cement to sludge. According to real situation, there are two drying technologies for customers' choice, sludge alkaline stabilization disposal technology and deep drying technology.

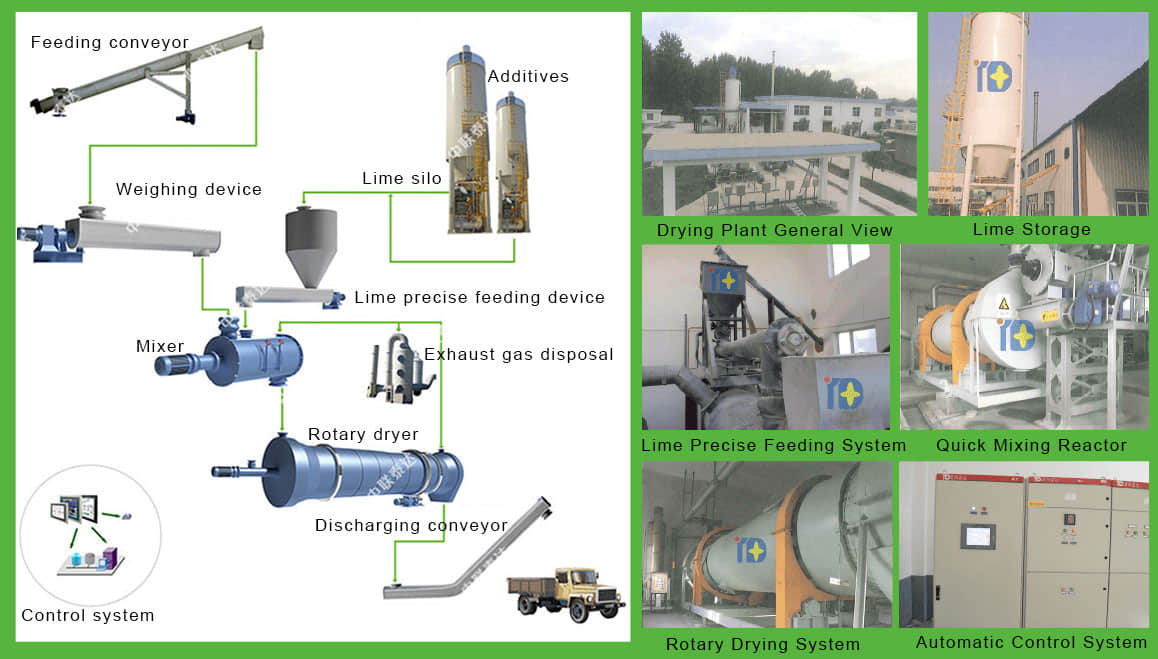

CAO Sludge+Calcium Akaline Stablization Drying System is a kind of drying, stabilization and recycling method developed by Taeda based on contemporary new technologies at home and abroad for sludge from municipal waste water treatment plants by using of additives. During disposal process, quick lime is used as additives, stabilizer and heat generating agent. After drying, dewatering and modification, sludge can be reused as stable inorganic matters. Besides replacing auxiliary materials in construction industry, dried products can also be used for brick making, which helps recycling of sludge. This technology is featured in no secondary pollution, high safety level, low investment and waste reutilization. Calcium hydroxide will become calcium oxide after dewatering. Based on this principle, additives can be recycled and reutilized after materials are calcined under high temperature, which realizes circular use of raw materials.

CAO drying system is very suitable for small and medium sized waste water treatment plants which regard landfill and construction utilization as final aims; especially suitable for waste water plants, industrial parks, waste water disposal stations which have online upgrading reconstruction and deodorization aims or used to deal with toxic and harmful sludge, like organic matter, dyestuff, inorganic matter and food.

More information you may be interested in:

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Input capacity | Power/kw | System area occupation/m2 | Notes | ||

| Running power | Installed power | Core equipment area | System area | ||

| 1t/h | 17.5 | 30 | 20 | 90-125 | provide complete, systematic technology and product service. |

| 2t/h | 22.5 | 40 | 24 | 125-175 | |

| 3t/h | 30 | 50 | 32 | 175-300 | |

| 4-5t/h | 45 | 70 | 48 | 300-400 | |

| 7.5t/h | 55 | 90 | 60 | 350-450 | |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.