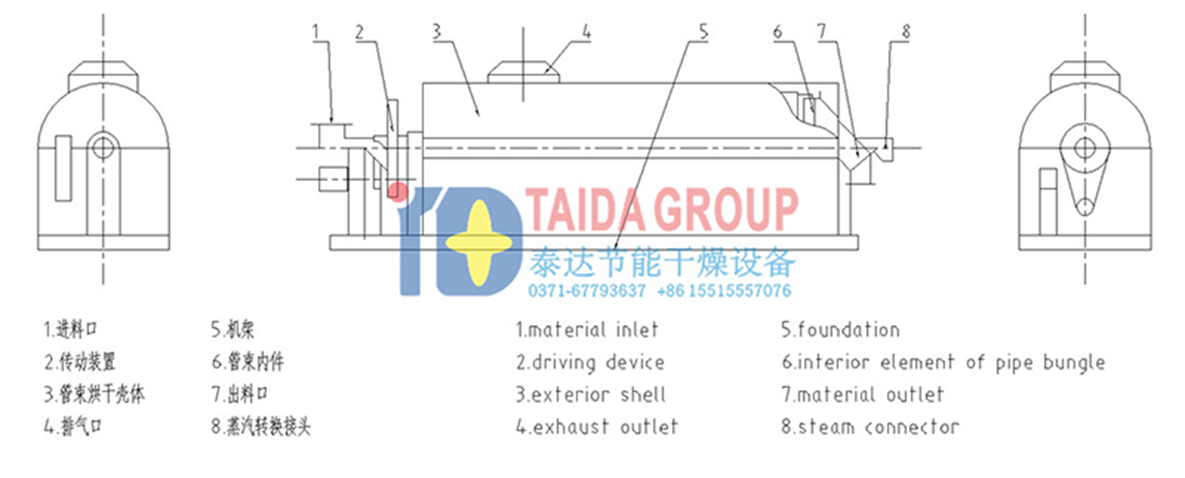

Taeda GZG tube bundle dryer is a kind of drying device which makes use of inner hot tube bundle heat exchanger rotating slowly to fulfill moisture evaporation aim. GZG is a type of indirect contact drying machine. There are rotatable heating tube bundles with inclined blades installed on the fixed dryer shell. Steam will enter tubes through rotary joints. After heat transfer, steam will become condensate water and be discharged out. Moisture contained in raw materials will become vapor after being heated out of tubes and these vapor will be discharged by dehumidifying fan. Raw materials will be lifted by blades on tube bundles and evenly drop on outer surface of heating tubes. Meanwhile, raw materials will be driven to discharge outlet and further dried.

GZG steam tube bundle dryer is featured in low heat consumption, wide drying application and large capacity. GZG dryer holds higher evaporation capacity and can be used to dry high moisture raw materials. With flexible drying ability, residence time of raw materlal in GZG steam tube bundle dryer can be adjusted according to different material property and moisture requirements. GZG stean tube bundle dryer can be used for both batch and continuous drying work (suitable for special drying work), Materials are dried in a negative and closed drying chamber. Whole drying process is characterized by clean working condition, low noise and small footprint.

Taeda GZG steam tube bundle dryer combines advantages of steam scrapper dryer and steam rotary drum dryer. Propeller steam tube bundles are steam heat exchanger. Materials are lifted repeatedly, pass through tube wall repeatedly and exchange heat with hot air in drum. Exchanging area is larger.

GZG steam dryer is driven by hollow shaft at collection end and dryer shell is fixed. Besides steam rotary joint and gearbox, there is almost no other quick wear parts. Both malfunction rate and running cost are low.

GZG steam dryer adopts steam as heat source. Vapor evaporated from drying chamber is less and moisture-carrier gas amount needed is small. Production environment is good and dust removal work is easy. For institutions with enough steam source, GZG steam dryer adds no extra running cost. It is a cost effective and environment friendly drying system.

For GZG steam dryer, materials will not directly contact with steam and drying temperature can be adjusted. Therefore, besides materials suitable for being dried by common dryer, TDGD dryer is especially suitable for drying heat-resistant material and materials which must be dried by steam. We can also provide pilot runing service to eliminate customers' concern.

| Model | Capacity(t/h) | Power(kw) | Weight(kg) | Heat transfer area(M2) | Overall dimension(mm) |

| GZG90 | 0.28-0.36 | 7.5 | 12 | 90 | 7647×1802×2628 |

| GZG150 | 0.45-0.6 | 15 | 15 | 150 | 9078×1862×2680 |

| GZG300 | 0.96-1.2 | 22 | 23 | 300 | 10520×2410×3150 |

| GZG400 | 1.3-1.6 | 30 | 30 | 400 | 10805×2660×3665 |

| GZG500 | 1.6-2 | 37 | 37 | 500 | 11380×2922×3994 |

| GZG600 | 1.9-2.4 | 55 | 55 | 600 | 12450×2986×4006 |

| GZG700 | 2.2-2.8 | 75 | 75 | 700 | 12306×3162×4584 |

| GZG800 | 2.6-3.2 | 90 | 90 | 800 | 12860×3382×4430 |

| GZG900 | 2.8-3.6 | 90 | 92 | 900 | 13810×3382×4430 |

| GZG1000 | 3.2-4 | 110 | 110 | 1000 | 14310×3500×4206 |

| GZG1200 | 3.8-4.8 | 132 | 132 | 1200 | 15480×3746×4900 |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.