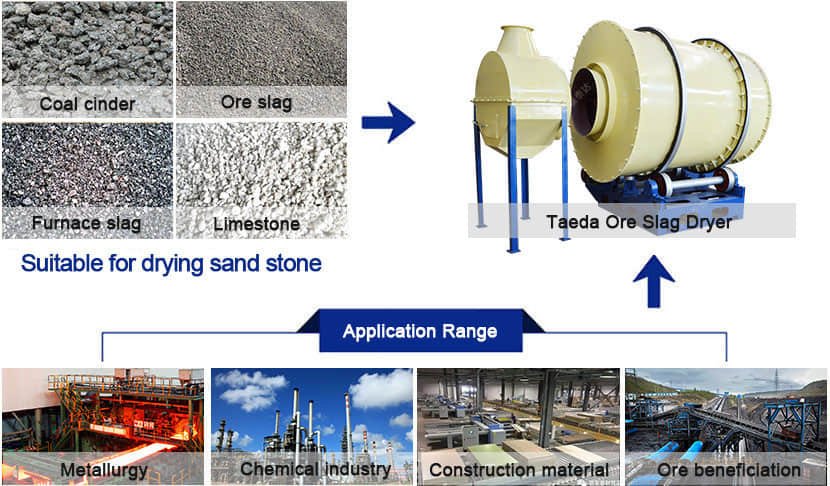

Taeda Slag Dryer is very suitable to dry wet slag represented by ore slag slag,like ore slag, coal slag/cinder, ore slag,iron slag, stone, clay, sand and other similar materials. Ore slag is residual slag produced during ore pressing project. It is a kind of recyclable resource. After proper processing, slag can be widely applied for chemical industry, metallurgy, construction material and hydraulic engineering. Slag is regarded as superior recycled materials. Because moisture content in ore slag is high, it is not easy to store and utilize. Proper drying system is necessary to reach drying aim for ore slag. Taeda slag dryer is developed based on advanced foreign technology. It holds very good drying effect for ore slag drying. Taeda ore slag dryer holds rational design, stable performance, high technology, large capacity, less energy consumption, high mechanical level and wide application range.

Working principle:

Taeda slag dryer consists of rotary drum, lifting plates, transmission part, support device and seal ring. Wet materials are sent to feeding hopper by conveying device. Through feeding hopper, raw materials will be sent to feeding end of mining dryer. Inclination angle of feeding end is larger than natural inclination angle of raw material so that raw material can flow to dryer smoothly. Mining dryer drum is a rotary drum which inclines slightly. Materials enter dryer from higher end. Hot air enters dryer from lower end. Materials contact with hot air countercurrently. There is also situation where materials and hot air enter dryer from samed end. Along with the rotation of drum, materials move to lower end under the force of gravity. During the moving process, wet materials are heated by hot air and moisture is evaporated. Dried products will be conveyed out through conveyor. There is lifting plates set inside drum wall and materials will be scattered. Thus, contact area between material and hot air is enlarged and drying speed is improved. Exhaust gas will pass by cyclone dust collector and pulse bag filter before discharging to air.

Slag rotary drum dryer holds strong overload resistance and large processing capacity. By adopting combined drying mode, Taeda slag dryer consumes less energy and cost less investment. High temperature exhaust gas can be recycled and thermal loss is less.

Running parameters of Taeda slag dryer can be adjusted ba

Taeda slag dryer is featured in simple operation, stable running performance, good seal effect and convenient seal performance. It is a ideal drying equipment. Whole system contains rotary drum, lifting plates, support device, seal device, heat source, dust collecting and electrical control. Rational structure and perfect workmanship makes Taeda slag dryer durable.

Whole drying system holds flexible configuration. We can configure feeder, heat source, conveying, dust collecting, product conveying and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Item |

Gradient (%) |

Rotational speedr/min) | Inlet air temperature(℃) | Capacity (t/h) | Power(kw) |

| MGT600 | 3-5 | 3-8 | ≤850 | Different Materials Different Capacity. | 3 |

| MGT800 | 3-5 | 3-8 | ≤850 | 4 | |

| MGT1000 | 3-5 | 3-8 | ≤850 | 5.5 | |

| MGT1200 | 3-5 | 3-8 | ≤850 | 11 | |

| MGT1500 | 3-5 | 3-8 | ≤850 | 15 | |

| MGT1800 | 3-5 | 3-8 | ≤850 | 18.5 | |

| MGT2000 | 3-5 | 3-8 | ≤850 | 22 | |

| MGT2200 | 3-5 | 3-8 | ≤850 | 30 | |

| MGT2400 | 3-5 | 3-8 | ≤850 | 37 | |

| MGT2600 | 3-5 | 3-8 | ≤850 | 40 | |

| MGT2800 | 3-5 | 3-8 | ≤850 | 55 | |

| MGT3000 | 3-5 | 3-8 | ≤850 | 75 | |

| MGT3200 | 3-5 | 3-8 | ≤850 | 90 | |

| MGT3400 | 3-5 | 3-8 | ≤850 | 110 | |

| MGT3600 | 3-5 | 3-8 | ≤850 | 150 | |

| MGT4000 | 3-5 | 3-8 | ≤850 | 190 | |

| MGT4200 | 3-5 | 3-8 | ≤850 | 200 | |

| MGT4500 | 3-5 | 3-8 | ≤850 | 260 |