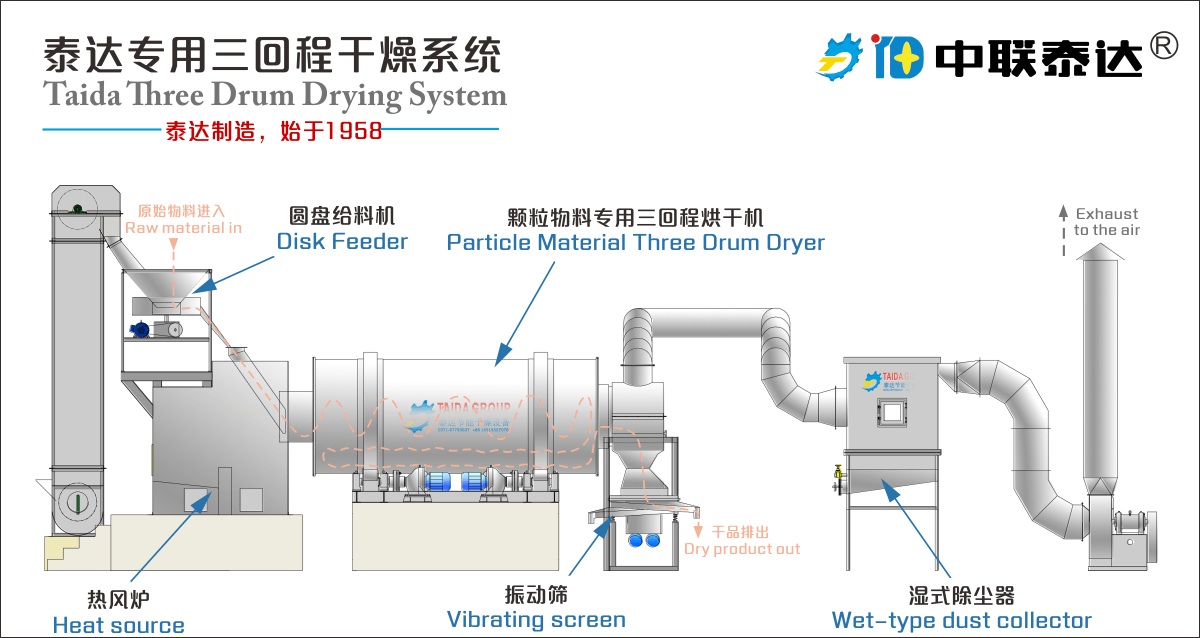

Sand stone dryer is also called stone/particles dryer. It is a kind of combined drying machine which always applied for construction material, metallurgy, beneficiation, chemical and cement industry. Taeda sand stone dryer is mainly suitable for drying ore slag, limestone, clay, river sand other other materials with high moisture and large bulk density. Taeda sand stone dryer mainly contains hot air furnace, rotary drum dryer, lifting plates, dispersing device, self cleaning device, transmission device, conveying equipment, support roller, seal device, cyclone collector, induced draft system and electrical control part. Taeda sand stone dryer is featured in rational design, perfect workmanship.

Taeda sand stone dryer adopts new advanced technology. There is a self insulation structure formed for inner, middle and outer drum. Special thermal design helps saving energy consumption. Heat exchanging effect and unit evaporation ability of Taeda sand stone dryer is better than common drum dryer. As an environmental friendly and energy saving drying equipment, Taeda sand stone dryer is a good replacement for tradtional rotary drum dryer in regard for drying river sand, artificial sand, silica sand, ore powder, coal slag, dry mix, yellow sand, clay, coal gauge, mixed material, coal ash, fly ash, gypsum, iron powder and limestone in construction, chemical and casting industries.

Taeda sand stone dryer holds strong overload resistance and large processing capacity. By adopting combined drying mode, Taeda sand stone dryer consumes less energy and cost less investment. High temperature exhaust gas can be recycled and thermal loss is less.

Running parameters of Taeda sand stone dryer can be adjusted ba

Taeda sand stone dryer is featured in simple operation, stable running performance, good seal effect and convenient seal performance. It is a ideal drying equipment. Whole system contains rotary drum, lifting plates, support device, seal device, heat source, dust collecting and electrical control. Rational structure and perfect workmanship makes Taeda sand stone dryer durable.

Whole drying system holds flexible configuration. We can configure feeder, heat source, conveying, dust collecting, product conveying and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

|

Item |

Capacity (t/h) Capacity will be different for different materials. | Power (Kw) | |||

| Fly ash | Clay | Slag | Sand | ||

| TDLT320.1 | 5~10 | 4 | 4~6 | 10~15 | 11 |

| TDLT320.2 | 10~15 | 6 | 6~8 | 15~20 | 11 |

| TDLT325.1 | 20~25 | 8 | 8~12 | 20~25 | 15 |

| TDLT325.2 | 25~30 | 10 | 12~15 | 25~30 | 15 |

| TDLT328 | 30~35 | 15 | 15~20 | 35~40 | 22 |

| TDLT330.1 | 35~40 | 20 | 20~25 | 40~45 | 30 |

| TDLT330.2 | 40~45 | 25 | 25~30 | 45~50 | 30 |

| TDLT332.1 | 45~50 | 30 | 30~35 | 50~60 | 44 |

| TDLT332.2 | 50~60 | 35~40 | 35~40 | 60~70 | 44 |

| TDLT336 | 60~70 | 40~45 | 40~45 | 70~80 | 60 |

| TDLT338 | 70~80 | 45~50 | 45~50 | 80~90 | 60 |

| TDLT340 | 80~90 | 50~60 | 50~60 | 90~100 | 74 |