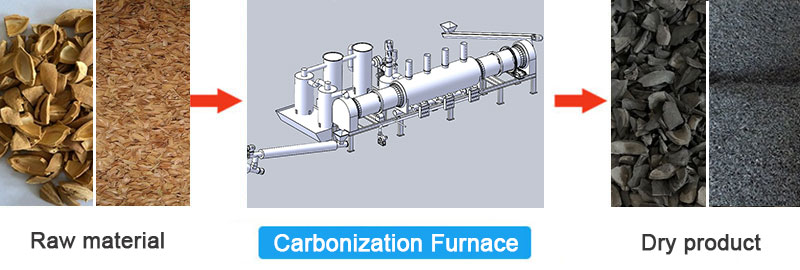

【Raw materials】: wood shavings, peanut shell, straw, nut shell, tree bark, coconut shell and palm shell and other various biomass wastes

【Work mode】: Continuous

【Capacity】: 0.5-2.5t/h

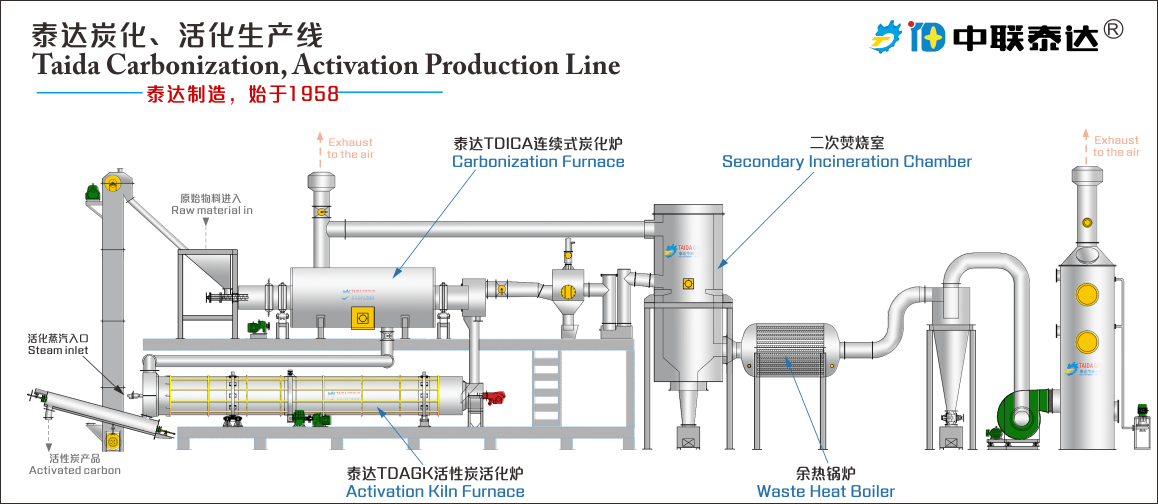

Continuous carbonization furnace is a kind of continuous carbonization machine which integrates rotary drum carbonization furnace and combustible gas recycling unit into one body. This series carbonization furnace can be used to carbonize wood shavings, peanut shell, straw, tree bark, coconut shell, palm shell and other various biomass wastes. Moisture of materials to be carbonized shall be lower than 15%. Final discharged product holds good quality and carbon content is higher than 80%. Continuous Carbonization Furnace produced by Taeda can meet different customers' demands and have enjoyed wide recognition among customers.

Continuous Carbonization Furnace produced by Taeda Company can be easily operated. It adopts horizontal continuous rotar drum which can do constant production and save labor force.

Continuous Carbonization Furnace can work constantly to reach to high yeild. Meanwhile,quality of final products can be guaranteed. Flue gas produced can be recycled. It consums less energy and causes less emission.

Taeda continuous carbonization furnace adopts high stantard SS310 texture. As professional manufacturer, we can give guarantee to carbonization equipment we provide.

Scientific structural design makes longer service life. Combustible gas can be recycled and reutlized as heat source for whole system.

| Model |

Output Capacity (kg/h) |

Power | Driving motor | Overal Dimensions (L×W×H) |

| TDICA0.6 | 300-500 | 5.5 | Frequency control | 10*1.1*1.2 |

| TDICA0.8 | 400-600 | 7.5 | 12*1.3*1.5 | |

| TDICA1.0 | 500-800 | 11 | 12*1.5*1.7 | |

| TDICA1.2 | 700-1200 | 15 | 14*1.7*1.8 | |

| TDICA1.5 | 1000-1500 | 18.5 | 14*2*2.2 | |

| TDICA1.6 | 1500-1800 | 22 | 17*2.1*2.2 | |

| TDICA1.8 | 1800-2500 | 30 | 20*2.3*2.5 | |

| TDICA2.0 | 2700-3200 | 37 | 20*2.5*2.7 | |

| TDICA2.2 | 3200-4000 | 45 | 20*2.7*2.8 | |

| TDICA2.5 | 4000-5000 | 55 | 20*3*3.1 | |

| TDICA3.0 | 5000-6000 | 75 | 20*3.5*3.8 |