【Raw materials】: new carbon, coal-ba

【Particle size】: columnar, particle

【Working principle】: continuous, steam activation

【Working temperature】: 950-1000℃

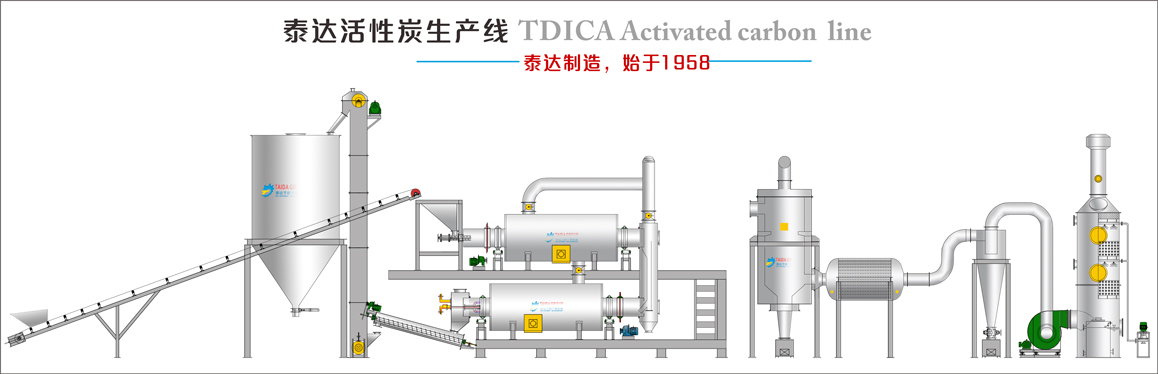

Taida TDICA series external heating activation furnace is developed based on advanced technology. It can be used to activate charcoal produced from biomass and coal. According to different application condition, it can be used for both carbonization and activation aim. TDICA series activation furnace consists of air-lock feeding device, rotary furnace, external heating room, heating unit, cooling discharger and tail gas disposal unit.

After pretreatment, raw materials will be sent into activation furnace where steam and protection gas will be sent into at the same time. Raw materials will be fully mixed by the special device installed in the furnace. Working temperature can be flexibly adjusted. Combustible gas produced during activation process will be discharged from furnace tail. For this series external heating activation furnace, whole process from feeding to discharging step can be controlled by automatic control system, which can reduce labor force intensity and maintain stable quality of final products.

Raw material's residence time can be adjusted in a wide range like 15 minutes to 9 hours to reach different final effects. Working temperature can be regulated ba

According to customers' needs, Taida External Heating Activation Furnace can be matched with steam activation pipe so that to improve activation effect. Compared with internal heating furnace, External Heating type holds lighter weight and is more suitable to be placed on high platform.

Scientific structural design makes longer service life. We can configure customers with feeding equipment, cooling equipment, exhaust heat utilization equipment, dust collecting equipment and purification equipment. Whole system holds reasonable design.

According to different utilization condition, customer can choose electricity, gas as heat source fuel for the activation furnace. We can also provide you suggestions for choosing most sutiable heat source equipment.

| Model |

Input Capacity (kg/h) |

Power | Driving motor | Overal Dimensions (L×W×H) |

| TDICA0.6 | 300-500 | 5.5 | Frequency control | 10*1.1*1.2 |

| TDICA0.8 | 400-600 | 7.5 | 12*1.3*1.5 | |

| TDICA1.0 | 500-800 | 11 | 12*1.5*1.7 | |

| TDICA1.2 | 700-1200 | 15 | 14*1.7*1.8 | |

| TDICA1.5 | 1000-1500 | 18.5 | 14*2*2.2 | |

| TDICA1.6 | 1500-1800 | 22 | 17*2.1*2.2 | |

| TDICA1.8 | 1800-2500 | 30 | 20*2.3*2.5 | |

| TDICA2.0 | 2700-3200 | 37 | 20*2.5*2.7 | |

| TDICA2.2 | 3200-4000 | 45 | 20*2.7*2.8 | |

| TDICA2.5 | 4000-5000 | 55 | 20*3*3.1 | |

| TDICA3.0 | 5000-6000 | 75 | 20*3.5*3.8 |