【Feeding size】:

【Feeding moisture】: 20%-40%(Internal+external)

【Capacity】: 0.5-70t/h

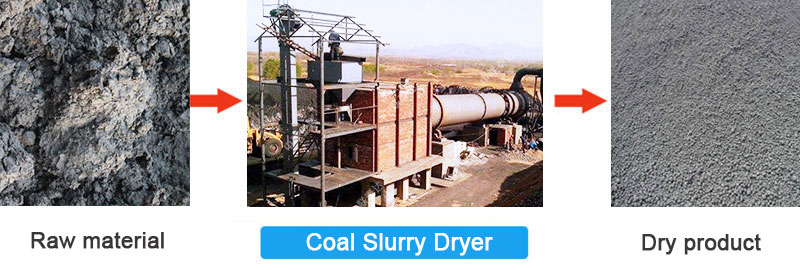

【Application】: Coal slime dryer Can be used to dry coal slurry, peat, clean coal, washed coal, mixed clean coal, lignite, raw coal, flotation clean coal, tailings and other similar viscous materials.

Coal slurry dryer is mainly designed for coal slurry according to special features of coal slurry. This Taida new type drying system can strictly control drying temperature and rotary speed. There are some good-quality lifting device, cleaning device and crushing device which can solve wall-sticking problem in coal slurry drying process.

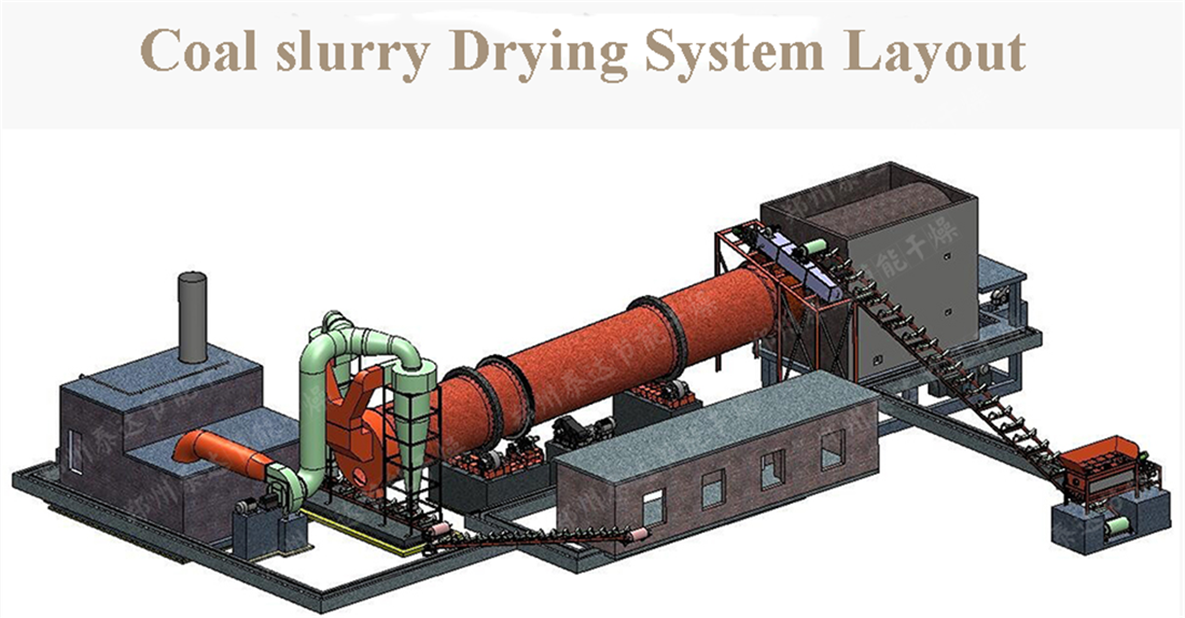

Raw materials will be sent to dispersing feeder. Then, raw materials will be sent to belt conveyor by screw. Then, raw materials will be led to incline lifting zone. With the rotation and inclination of drum, materials will be lifted to top and drop down, which will form a material curtain. Hot temperature flue gas will pass by wet materials and form heat conduction and heat exchange. Wet materials will be preheated and partial steam will be evaporated. Meanwhile, the temperature of hot flue gas will drop sharply. After being preheated, wet materials will enter middle temperature drying zone. Majority of moisture will be evaporated here. There will be a mixing process between materials and flue gas until materials’ moisture enter a standard value. Then, materials will be discharged out. After heat exchanging, exhaust gas which contains a great amount of steam and dust will be dedusted coarsely by first-class cyclone dust collector. Then, secondary-class bag filter or wet dust collector will carry out elaborate dust removal. After being purified, dust content of exhaust gas will be controlled at below 50mg/m³, which can definitely meet emission standard. Here, the whole drying process is finished.

As professional coal slurry dryer manufacturer, Zonelion Taeda takes transportation convenience into consideration during manufacturing process. Compared with other similar system, Taeda coal slurry dryer can save 30% installation speed. At present, Taeda coal slurry dryer has been widely applied in many coal enterprised different regions like Yunnan, Guizhou, Ningxia, Inner Mongolia, Shandong, Shanxi, Henan, Hebei, Anhui, Jiaolong River, Jiangsu and Indonesia. It has brought great benefits for both society and economy.

Taeda coal slurry dryer is installed with new feeding and discharging device, which avoids clogging, discontinuous, uneven and material returning phenomena. Correspondingly, dust collecting load is reduced. Taeda coal slurry dryer adopts self-aligning tug device, which makes the match of supporting wheel and rolling ring in linear contact. Thus, both abrasion and power loss can be decreased.

Taeda coal slurry dryer is featured in high thermal efficiency, low energy consumption, high overload resistance, large capacity, less fuel consumption and low drying cost. It adopts fair current drying mode where flue gas and wet materials flow to dryer from same end. High temperature flue gas helps realize high evaporation capacity. Meanwhile, temperature at dryer outlet is low and thermal effciency is high.

During drying process, Stable and thorough section material curtain can be formed. Mass and heat exchange is done fully. New internal structure enhances cleaning and heat conduction function to dispersed materials. Wall sticking in drum is eliminated. New design holds better adapability to different moisture and stickness.

| Model | Drum diameter(M) | Drum length(M) | Drum slope(%) | Motor power(kw) |

Drum rpm (r/min) |

Occupation area(m²) |

| TDGT-12100 | 1.2 | 10 | 3-5% | 7.5 | 3-8 | 100 |

| TDGT-15120 | 1.5 | 12 | 3-5% | 10 | 3-8 | 150 |

| TDGT-15150 | 1.5 | 15 | 3-5% | 18.5 | 3-8 | 200 |

| TDGT-18120 | 1.8 | 12 | 3-5% | 11 | 3-8 | 260 |

| TDGT-22120 | 2.2 | 12 | 3-5% | 18.5 | 3-8 | 260 |

| TDGT-22140 | 2.2 | 14 | 3-5% | 18.5 | 3-5 | 300 |

| TDGT-22160 | 2.2 | 16 | 3-5% | 30 | 3-5 | 300 |

| TDGT-24140 | 2.4 | 14 | 3-5% | 30 | 3-5 | 350 |

| TDGT-24180 | 2.4 | 18 | 3-5% | 37 | 3-5 | 400 |

| TDGT-24220 | 2.4 | 20 | 3-5% | 37 | 3-5 | 450 |

| TDGT-30200 | 3.0 | 20 | 3-5% | 55 | 3-5 | 500 |

| TDGT-30220 | 3.0 | 22 | 3-5% | 75 | 3-5 | 500 |

| TDGT-40250 | 4.0 | 25 | 3-5% | 210 | 3-5 | 800 |