Capacity: 5-500t/h

Working mode: 24h/day

Application range: Suitable for drying coal slime, lignite, Mongolian coal, peat, coke, semi-coke, clean coal, mixed clean coal, flotation clean coal, raw coal, tail coal and other similar viscous materials;

TDMT series coal drying upgrading system is a new type of drying equipment specially developed for coal by our company after years of practical experience. It is designed mainly fo upgrading coal with 15-50% moisture content, such as Mongolian coal, Indonesian coal, flotation clean coal, mixed coal, press filter tailings, medium coal, semi-coke, coal slime and lignite. Drying ability of TDMT system ranges from 40-80kg/m3.h and its thermal efficiency is more than 90%. In terms of working principle, TDMT system belongs to dehydration and quality improvement process. It makes use of rotary drum drying process to effectively reduce sulpur and ash content ofcoal after four-level low temperature drying process while ensuring quality of coal to be dried remains unchanged. Moisture content of coal material is reduced to less than 12% so that to reduce transportation cost and increase calorific value of lignite. Correspondingly, coal material processed after TDMT system can meet application requirements of power plants. At the same time, coal materials can be processed into coal briquettes product to solve spontaneous combustion problem of some coal types. Calorific value of disposed coal materials can be increased by more than 30%. Final products from TDMT system can be directly used as thermal coal to replace bituminous coal or anthracite in thermal power plants.

Special features of coal materials are fully taken into consideration during designing of DMT series efficient high- energy-saving coal drying upgrading system. Aimed at high moisture feature, we make special design for internal drum, which improves thermal efficiency and effectively avoids over drying phenomenon. According to different requirements from market demand, environment, coal feature, production capacity and environment protection, we provide optimal system configurations so that to meet different customers' requests. At present, our coal drying upgrading system has been developed to 6th generation. A large-scale and serialized energy-saving coal drying upgrading system has been formed. There are different internal structures for coal drying upgrading system in order to gurantee drying and upgrading effect.

From principle of coal upgrading, TDMT coal drying upgrading system is mainly classified into: ① drying and upgrading of coal slime; aimed at coal slime after pressing and filtering, use drying and dewateringprocess to achieve quality improvement function; ② drying and upgrading of inferior coal, such as lignite and Mongolian coal. In terms of equipment specifications, diameter of drying equipment ranges from 1.0 to 4.2 meters and length ranges from 15 meters to 38 meters. Daily processing capacity ranges from 100 to 3000 tons. After drying, the moisture can be reduced to 10±2%. For coal materials with high moisture, whole drying process can realize non-bonded, non-clogging, safe and reliable, unobstructed, good loosening effect, and strong evaporation capacity. At present, this set of equipment has been installed in many other coal enterprises from Yunnan, Guizhou, Ningxia, Inner Mongolia, Shandong , Shanxi, Henan, Hebei, Anhui, Heilongjiang, Jiangsu, Indonesia and put into use. TDMT coal drying upgrading system has created considerable economic and social benefits.

Taeda TDMT coal drying upgrading production line is specially designed for coal mateials. There are multiple combined structures installed in dryer. During designing process, Taeda technical team takes special features of coal materials like flammability, easy explosion, high moisture content, stickiness and wall sticking. TDMT coal drying upgrading system is set with dispersing cleaning device. We can also dispatch professional engineers on site for providing service on layout plan, process design and solution support.

Taeda TDMT coal drying upgrading system processing capacity can reach 200dun. Materials can be fed to dryer continuously and evenly. Whole system is done in an anaerobious and closed environment. Matched with clean coal firing combustion technology, TDMT system can realize low dust removal burden during continuous and large scale production process. There is almost no dust leak, which makes working environment better and emission up to standard.

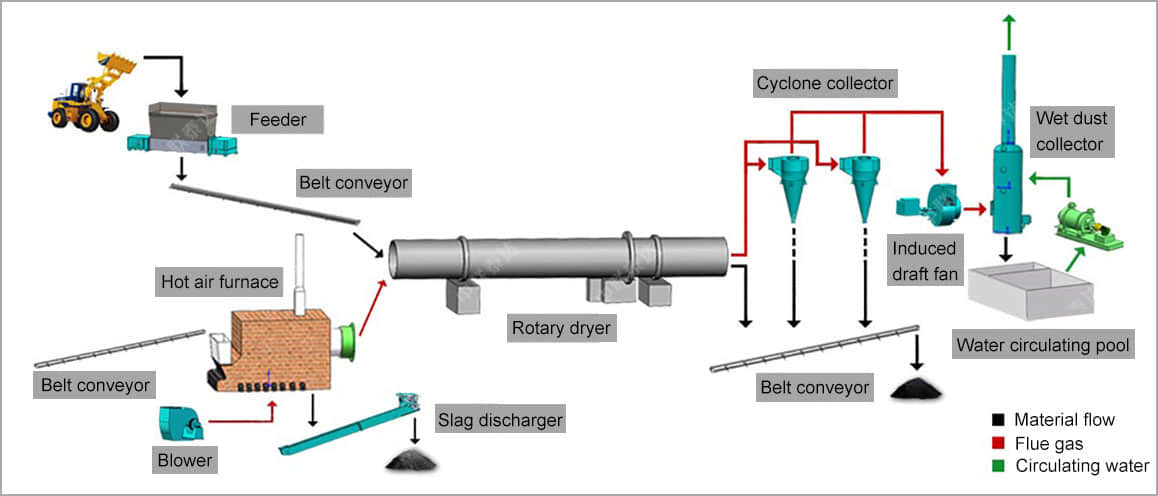

Taeda TDMT coal drying upgrading system is featured in high centralization level and complete configuration. Whole system contains feeder, heat source, dryer, dust collector, discharger and electrical control. Parameters like temperature and pressure can be tested and adjusted flexibly. Whole system consumes less labor force and total running is low.

Taeda TDMT coal drying upgrading system can match with various heat source like coal (chain furnace, hot air furnace, boiling furnace and coal gasifier), coal gas (from coal gasifier, coke oven gas and oven gas), biomass pellet, diesel, gas, steam and exhaust heat. It adopts good thermal insulation design, which makes higher thermal efficiency. Compared with traditional dryer, its running cost is 20% lower at least.

TDMT coal drying upgrading system designed by Taeda company is featured in complete configuration, flexible heat source option, large capacity and high thermal efficiency. It is widely applied for drying and upgrading of various coal slime, lignite,coal peat, clean coal, semi-coke, Mongolian coal, coke, mixed clean coal, floated clean coal, raw coal, tailings and lignite.

| Item | Model | Capacity t/h)) | Optional fuel | Standard configuration |

| TDMT Coal Drying Upgrading Production Line | φ1.6 | 10-450 | Coal, coke, gas, coal gas, oil, biomass and etc. | Stiring&dispersing silo, feeding conveyor, dryer, hot air furnace, material collector and scrubbing tower. |

| φ2 | ||||

| φ2.4 | ||||

| φ3 | ||||

| φ3.4 | ||||

| φ4 | ||||

| φ4.2 | ||||

| Typical Materials | ||||

| Coal slurry | Coal slime | Semi coke | Lignite | |

| Clean coal | Mogolian coal | Raw coal | Tailings | |

| Mixed clean coal | Coal ash | Filtered tailings | Floated clean coal | |

General heat source

suitable for a variety of heat sources, not restricted by heat source

Low operating costs

Low energy consumption and low operating costs

Environmental protection

use various of dust collectors to meet local environmental standards

Quality control

High-precision process equipment, strict quality control

Support customization

customized equipment according to customer needs

Technical guidance

professional and technical personn-el on-site guidance operation

Automatic operation

automatic operation, simple operati-on and saving manpower