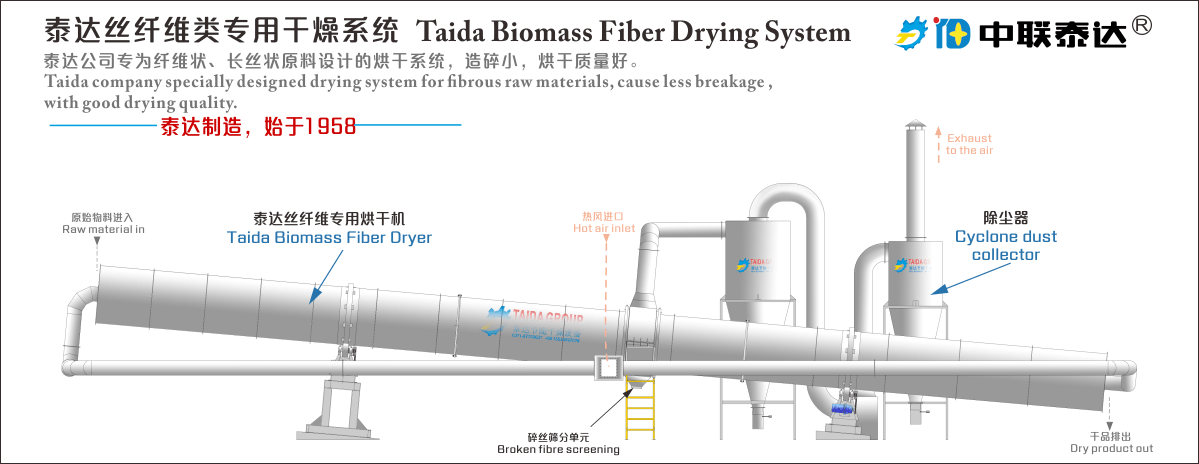

Taeda® biomass fiber material drying system is suitable for drying coconut shred, palm silk, coconut fiber, palm fiber and other similar light biomass fiber materials. Advantages of new biomass fiber material dryer mainly centers on its working principle. It combines working principle of rotary drum dryer, screen machine and combing equipment. After shredding, long silk enters inlet of long rotary drum. During slow moving process, fiber materials are dried. In front half section, hot air contacts with raw material fair currently and moisture is evaporated fast. In rear half section, hot air contacts with material counter-currently. Meanwhile, internal structure of biomass fiber dryer is specially designedf or long silk materials. Different from common lifting plate, its inner structure causes less damage to material shape and holds better combing effect. At present, Taeda fiber biomass material dryer enjoys great popularity at home and abroad.

TDMFB biological fiber drying system adopts new drying technology. Specially designed for long fiber biomass materials, it can meet customers’ drying and reutilization demands for coconut shred, palm fiber and other materials which cannot be dealt with by common drying equipment. TDMFB system is characterized by safety, intelligence, energy conservation, pollution free, high efficiency and high yield. Besides this kind of drying technology, Taida can also provide whole set of solution including opening, crushing, carbonizing, activating, pelleting and baling to meet different customers’ demands. TDMFB drying system can reduce coconut fiber’s moisture from 30%-45% to below 18% rapidly. Besides coal, diesel, gas, electricity and other common fuel, TDMFB system can also use wood, straw and fruit shell and other waste materials as heat source, which realizes reutilization of wastes and reduces running cost. Final dried products hold bright color, high strength and good flexibility.

Design of Taeda biomass fiber dryer fully takes features of coconut fiber and palm fiber into consideration such as long fiber, easily breaking and combustible. Taeda adopts special technology so that to guarantee simple operation, high capacity, low energy consumption and low production cost.

Considering customers for biomass fiber drying always come from coastal areas, we provide flexible cost effective options for customers for heat source section. Customers can use coal, natural gas, diesel, wood, palm shell and biomass pellets as fuel.

Relying on long drum design, hot air utilization efficiency is high and thermal loss is less. While manufacturing, we fully takes delivery and intallation convenience into consideration. Whole system adopts section-division and stack mounting design.

Whole drying system holds flexible configuration. We can configure dewatering equipment, feeder, crusher, heat source, conveying, dust collecting, elevation, cooler and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Specifications | Dimension | Capacity(T/H) | Moisture(%) | Power(Kw) | Occupation area |

| TDMFB1416 | 1.4×16m | 0.3-0.5 | 45%-15% | 20-35 | 8×24 |

| TDMFB1620 | 1.6×20m | 0.4-1.0 | 25-40 | 8×30 | |

| TDMFB1824 | 1.8×24m | 1.0-1.5 | 30-45 | 8×38 | |

| TDMFB2230 | 2.2×30m | 1.4-2.1 | 35-50 | 10×46 | |

| TDMFB2336 | 2.3×36m | 2.2-2.5 | 40-55 | 10×50 | |

| TDMFB2836 | 2.8×36m | 3-5 | 50-75 | 12×50 |