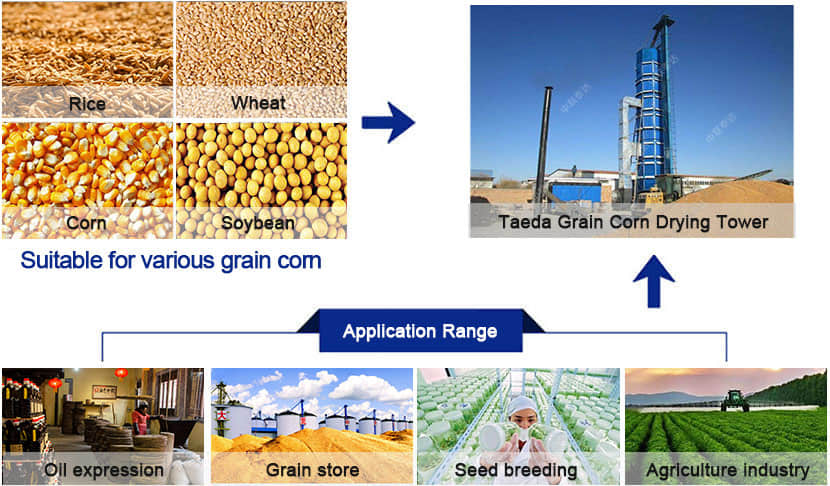

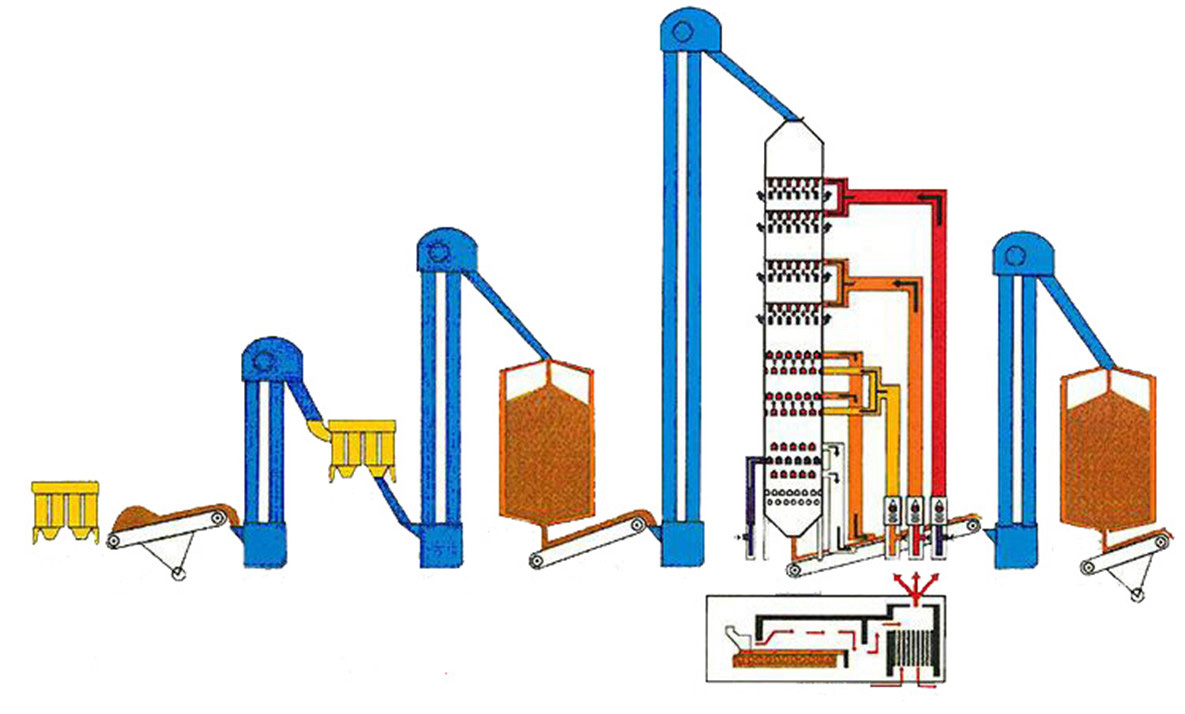

Full continuous drying theory is applied for continuous grain dryer. Grains flow into the grain drying tower through the feeder on the top of the drying machine, and then flow into grain column slowly by gravity. Grains are dried first by hot-air blower, then cooled by cold-air blower below the machine, and at last discharged through the bottom of the dryer. It is widely used for drying paddy, corn, rapeseed, soybean, wheat, sorghum, peanuts, betel nuts and other granular grains. The moisture can be 2-30% lower after drying by this drying system.

According to different types of grains, customers can adjust drying temperature. Low temperature technology protects grains from being damaged.

There are various inlet temperatures. This machine can make the materials at outlet presented as small particles or powder which provides convenience for next process.

Continuous grain dryer is designed for outdoor style without the need of building workshop. Galvanized steel plate is applied for air net and main parts. The whole machine has good appearance and sealing as well as long working life, and can be operated all day outdoors at any condition.

Equipped with reasonable air duct, hot air can enter drying tower evenly and moisture can be fully discharged out. Grain corn materials will roll and stir repeatedly in drying channel, which make sure good drying effect and high energy utilization rate.

| Model | Capacity(t/d) | Moisture released(%) | Energy consumption | Hot air temperature(℃) | |||

| corn | rice | corn | rice | (MJ/kgH2O) | corn | rice | |

| TDT-100 | 100 | 130-200 | 13-15 | 4-5 | <6.5 | 100-135 | <66 |

| TDT-120 | 120 | 160-250 | 13-15 | 4-5 | <6.5 | 100-135 | <66 |

| TDT-150 | 150 | 200-300 | 13-15 | 4-5 | <6.5 | 100-135 | <66 |

| TDT-200 | 200 | 300-400 | 13-15 | 4-5 | <6.5 | 100-135 | <66 |

| Note | Capacity of other materials may differ | ||||||