【Feeding size】:

【Feeding moisture】: 55%-85%

【Capacity】: 0.5-15t/h

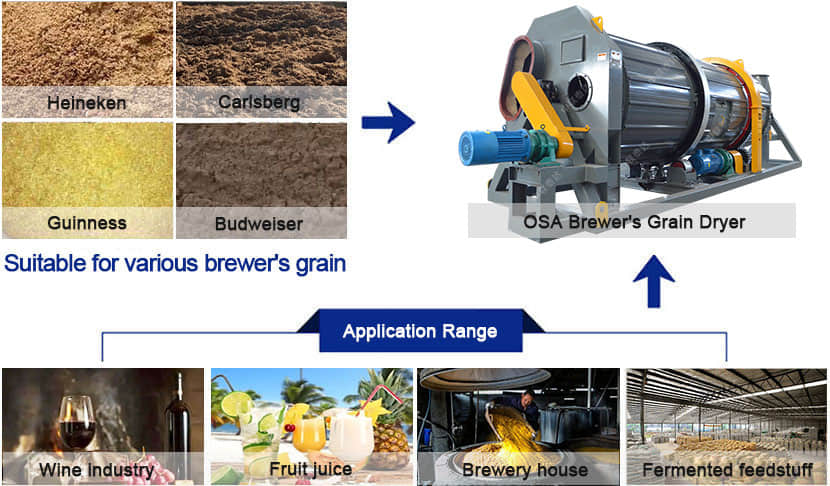

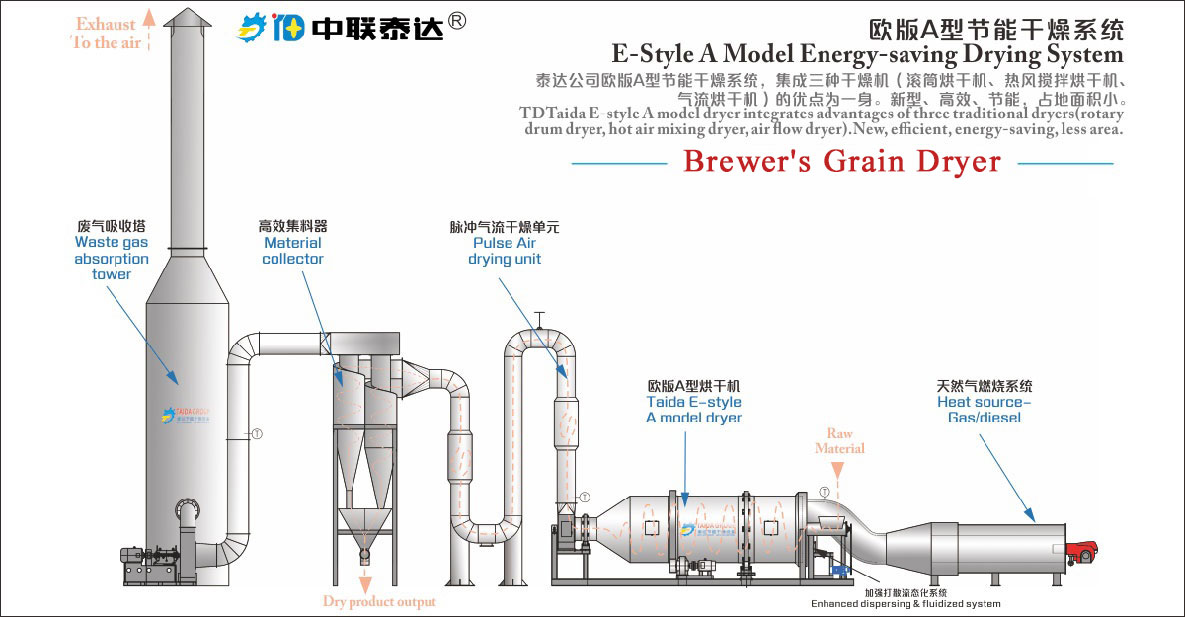

Taeda® brewery grain dryer can be used to dry various brewery grain , beer yeast powder and malt residues. It is suitable for high capacity continuous brewery grain drying work. It is featured in large capacity, small footprint, low energy consumption, stable running performance and special design. Generally speaking, there are great amount of brewery grain produced every day in brewering house. In terms of features of brewery grain like easily going bad, high initial moisture and viscosity, we design special modular and structure aimed at these features. There is high speed dispersing shaft installed inside drum so that quality of final product can reach optimal status during drying process. Moisture of dried brewery grain is about 10% and can be used as high-protein feedstuff, which realizes mechanical, industrial and automatic aim for brewery grain processing. Taeda® brewery grain dryer holds many advantages like high mechanical, large capacity, continuous production, convenient operation, low malfuction rate, less maintenance cost and low investment cost.

Taeda third generation Brewer grain dryer is especially designed for drying brewery grain materials. Features of brewery grain materials are fully taken into consideration during design process. It can reduce materials' moisture to 10% one step. Meanwhile, it can also work with dewatering machine so that to reach higher capacity and lower cost.

Taeda OSA brewery grain dryer adopts new drying concept which can meet continuous large scale drying work of Brewer grain. Meanwhile, final product holds good nutrition content and color. With a set of high speed dispersing shaft in drying, raw material can efficiently exchange heat with vortex hot air so that moisture can be evaporated soon and final product holds good quality.

Relying on scientific design, for same capacity, total length of OSA Brewer grain dryer is only half of triple pass dryer and one third of common drum dryer. Therefore, OSA dryer holds small footprint and its heat radiating area is smaller than common dryer. With high energy utilization and low thermal loss, OSA dryer is more energy saving.

Whole drying system holds flexible configuration. We can configure dewatering equipment, feeder, crusher, heat source, conveying, dust collecting, elevation, cooler and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Model | Transmission motor power | Fan power | Dispersing power | Weight | Overall dimension(W*L*H) |

| TDJZⅠ | 4-4.5 KW | 7.5 KW | 3KW | 6.5t | 1.5×4.5×1.7m |

| TDJZⅡ | 5.5 KW | 11 KW | 4KW | 9.5t | 1.6×5.5×2.0m |

| TDJZⅢ | 7.5 KW | 15 KW | 5.5KW | 12.5t | 1.8×6.5×2.0m |

| TDJZⅣ | 11 KW | 18.5 KW | 5.5KW | 18.5t | 2.4×8.5×2.5m |

| TDJZⅤ | 15 KW | 22 KW | 5.5KW | 24t | 2.6×8.5×2.5m |

| TDJZⅤI | 18.5 KW | 45 KW | 7.5KW | 32.2t | 3.0×10.5×3.0m |

| TDJZⅤII | 22 KW | 75 KW | 11KW | 40t | 3.0×11×3.0m |

| Brewery grain moisture | Before drying: 55-85%, after drying:≤13, dewatering process is recommened to be done first. | ||||

| Output capacity | 0.5-16t/h, depends on raw material and moisture content. | ||||