【Feeding size】:

【Feeding moisture】: 30-85%

【Capacity】: 0.5-10tph

Taeda leaf stem grass straw dryer is specially designed for drying staw, elephant grass, seaweed, water grass, alfalfa grass, reed grass, setaria and oats. Because majority of fodder materials are steam and straw, these kind of materials are also called leaf stem grass materials. Taeda fodder dryer is a kind of new drying system featured in continuous production, energy conservation, large capacity and good drying effect. After side cutting or crushing, long stem materials will enter dryer. Leaf materials can enter dryer directly or enter dryer after being cut into small silk shape. Drying process holds no effect to color and dried products are with good taste. For drying high added value leaf chip materials, Taeda fodder dryer holds high efficiency, low labor force and good drying effecT. At present, Taeda fodder dryer has been widely applied for multiple ginko leaf factories.

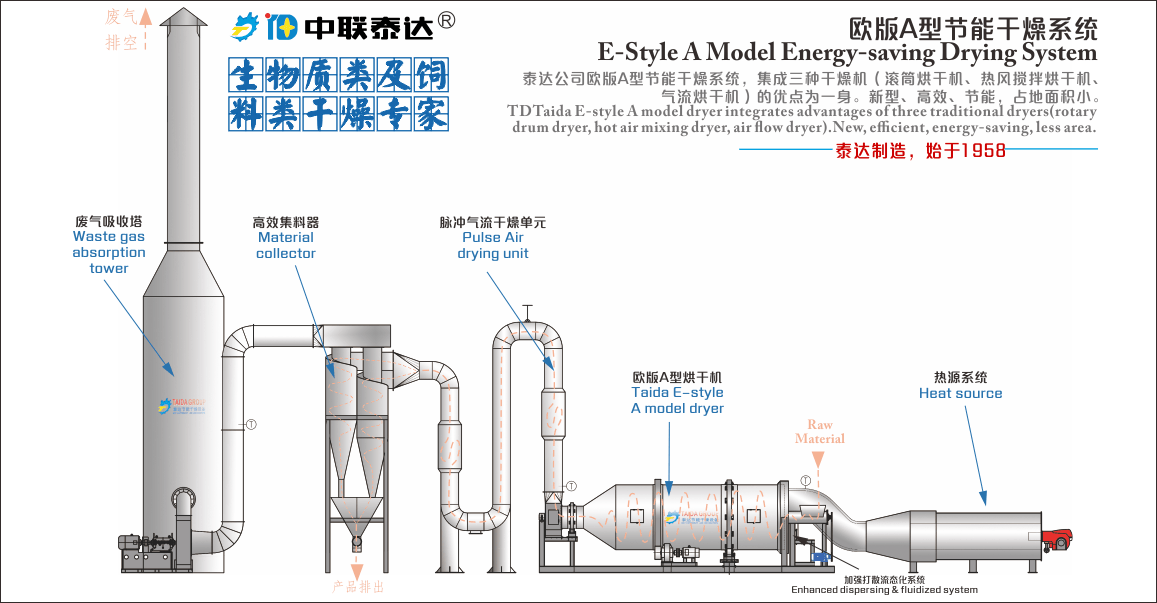

Taeda new fodder dryer is developed and optimized based on fodder materials. It combines working principles of rotary drum dryer, hot air stirring dryer and airflow dryer. Under the function of pushing force of rotary drum dryer, wet materials form fluidization layer and hot air continuously contact with wet materials. According to moisture difference, heat exchanging process is carried out gradually based on time period so that to increase material's heating area, improve drying efficiency and reduce drying cost.

Taeda Stem/leaf dryer fully takes features of biomass stem leaf fodder materials into consideration like easily color changing, with thermal value, small bulk density and high moisture content. It can reduce moisture of cocopeat to 10% one time. It is characterized by high efficiency, large capacity, stable operation, low energy consumption and low running cost.

Taeda new stem fodder material dryer adopts new drying concept which can meet continuous drying task and well maintain nutrition and color. There is a set of high speed dispersing shaft installed on dryer so that to guarantee efficient drying and evaporation and get good quality final products.

Relying on scientific design, for same capacity, total length of OSA stem/leaf dryer is only half of triple pass dryer and one third of common drum dryer. Therefore, OSA dryer holds small footprint and its heat radiating area is smaller than common dryer. With high energy utilization and low thermal loss, OSA dryer is more energy saving.

Whole drying system holds flexible configuration. We can configure dewatering equipment, feeder, crusher, heat source, conveying, dust collecting, elevation, cooler and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Specification | TDOSA-Ⅰ | TDOSA-Ⅱ | TDOSA-Ⅲ | TDOSA-Ⅳ | TDOSA-Ⅴ | TDOSA-Ⅵ | |

| OSA Dryer | Power | 4-4.5 KW | 5.5 KW | 7.5 KW | 11 KW | 15 KW | 18.5 KW |

| Dispersing power | 3kw | 3kw | 5.5kw | 7.5kw | 11kw | 11kw | |

| Capacity | 0.5t/h | 1.5t/h | 2.5t/h | 3t/h | 3.5t/h | 5t/h | |

| Overall dimension(L*W*H) | 1.5*5.5*2 | 1.8*5.5*2 | 2.5*9.5*2.2 | 2.8*9.5*2.5 | 3.0*10*2.8 | 3.0*11*3.0 | |

| Applicable material | Alfafa, forage grass, mulberry protein, leaf, elephant grass, fodder, straw, seaweed, water plant, ginko leaf and tea. | ||||||

| Drying effect | Moisture can be reduced to 8-30% from 85%. | ||||||