【Feeding size】:

【Feeding moisture】: 35-70%

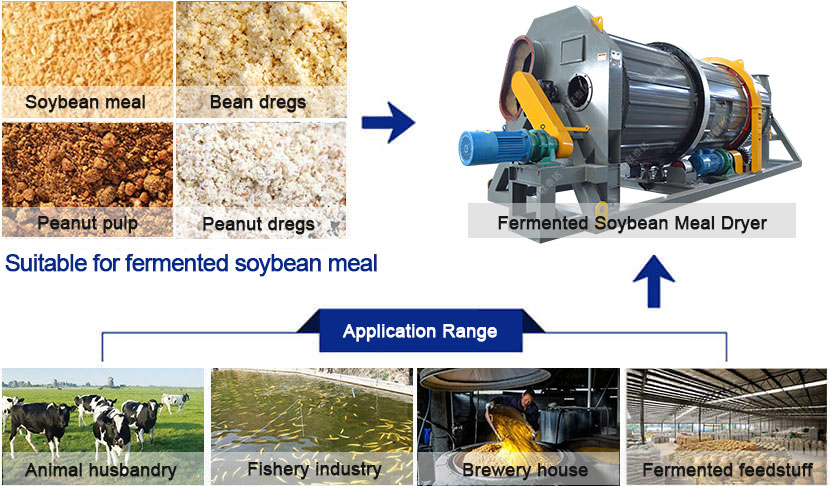

【Application range】: Applied for feedstuff, agriculture, oil pressing, aquatic product, animal husbandry, environment protection and other relevant industries.

【Applicable material】: Suitable for drying fermented soybean meal, bean pulp, bean dregs, yellow soybean meal, peanut pulp, peanut dregs, soybean oil residues and other similar materials.

Taeda® fermented soybean meal dryer can be applied to dry bean pulp, fermented bean pulp, bean cake, peanut pulp, peanut residue and bean dregs materials. Fermented soybean beam dryer is dryer designed for fermented bean pulp materials in particular. It is featured in large capacity, small footprint, low energy consumption and stable running performance.

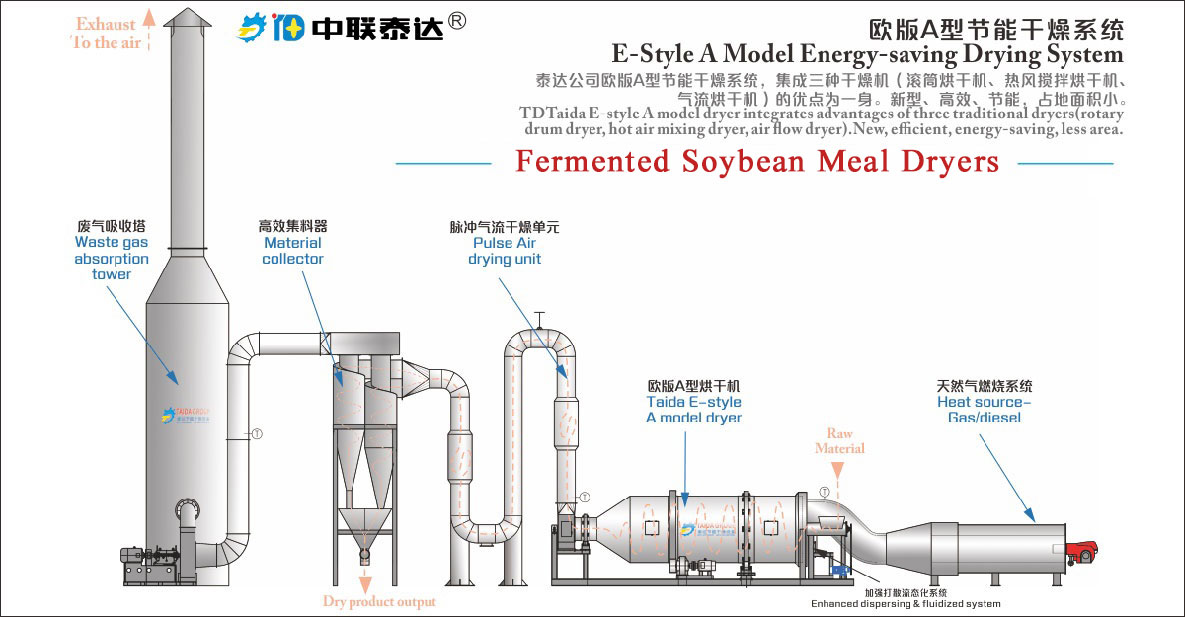

In terms of design, fermented soybean meal dryer adopts advantages of European drying systems like high efficiency, low energy consumption and low exhaust emission. Aimed at features of bean pulps, Taeda develops the whole set of fermented soybean meal dryer which can reduce moisture to lower than 12% one time. It can fully make use of thermal energy and make sure soybean meal heated evenly. Final products from fermented soybean meal dryer holds golden color and high nutrition content. Whole drying process consumes much less energy than common drying systems. Taeda fermented soybean meal dryer can make comprehensive feedstuff utilization of fermented soybean meal come true. Dried feedstuff soybean meal and peptide product is featured in high energy, easy absorption, tasty smell and high added value.

Fermented soybean meal product from Taeda newly designed soybean meal dryer holds about 15-20% Acid soluble protein and 48%-50% crude protein. Beneficial bacterium and other nutrition ingredients are well maintained.

At present, Taeda fermented soybean meal dryer has been widely applied at home and abroad for fermented feedstuff plants and bio-tech companies.

Zonelion Taeda fermented soybean meal dryer is an efficient and reliable drying system specially designed for drying bean pulp, fermented bean pulp, bean cake, peanut pulp, peanut dregs and bean residues.

High speed dispersing system is installed at cross section of dryer. Match with proper air accelerator and vortex generation device, there will be boiling material curtain formed. Efficient heat exchanging helps evaporation and temperature decrease. It is suitable for drying work of sticky fermented bean pulp.

Relying on scientific design, for same capacity, total length of OSA soybean meal dryer is only half of triple pass dryer and one third of common drum dryer. Therefore, OSA dryer holds small footprint and its heat radiating area is smaller than common dryer. With high energy utilization and low thermal loss, OSA dryer is more energy saving.

Whole drying system holds flexible configuration. We can configure dewatering equipment, feeder, crusher, heat source, conveying, dust collecting, elevation, cooler and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Item | Dryer | Power of ID Fan | Overall Dimensions (L*W*H) | Mixing & Dispersing Device | Pulse Drying Device | |

| Power | Feeder | |||||

| TDOSA-Ⅰ | 4-4.5 KW | 1.1KW | 5.5 KW | 1.5*5.5*2 | We can match | optional |

| TDOSA-Ⅱ | 5.5 KW | 1.5KW | 5.5 KW | 1.8*5.5*2 | ||

| TDOSA-Ⅲ | 7.5 KW | 1.5KW | 11 KW | 2.5*9.5*2.2 | Fixed Z-shaft lifting system | optional |

| TDOSA-Ⅳ | 11 KW | 2.2KW | 15 KW | 2.8*9.5*2.5 | ||

| TDOSA-Ⅴ | 15 KW | 3KW | 18.5 KW | 3.0*10*2.8 | or mixing or dispersing device | optional |

| TDOSA-Ⅵ | 18.5 KW | 3KW | 22 KW | 3.0*11*3.0 | ||