Capacity: 1-6t/h

Working mode: 24h/day

Application range: Suitable for drying various fermented materials, like bean pulp, bean dreg, brewery grain, spent grain, malt slag, DDGS, BGS, spray corn husk, cocopeat, furfural residue, sugar residue, soybean sauce residue, cassava residue, medicine residue, pomace and etc.

Fermented feed is a kind of feed which uses microorganisms and compound enzymes as biological feed starter strains to convert feed materials into fermented feed that integrates microbial cell proteins, biologically active small peptide amino acids, microbial active probiotics, and compound enzyme reparations into a whole. Fermented feed can not only make up for the amino acids that are easily lacking in conventional feed, but also can quickly transform the nutrient components of other rough feed ingredients so that to enhance digestion, absorption and utilization effect. Compared with other feeds, fermented feeds with 40% moisture content have significant advantages. It can increase height of small intestinal villi of weaned piglets, lower pH value in stomach and protect intestinal mucosa.

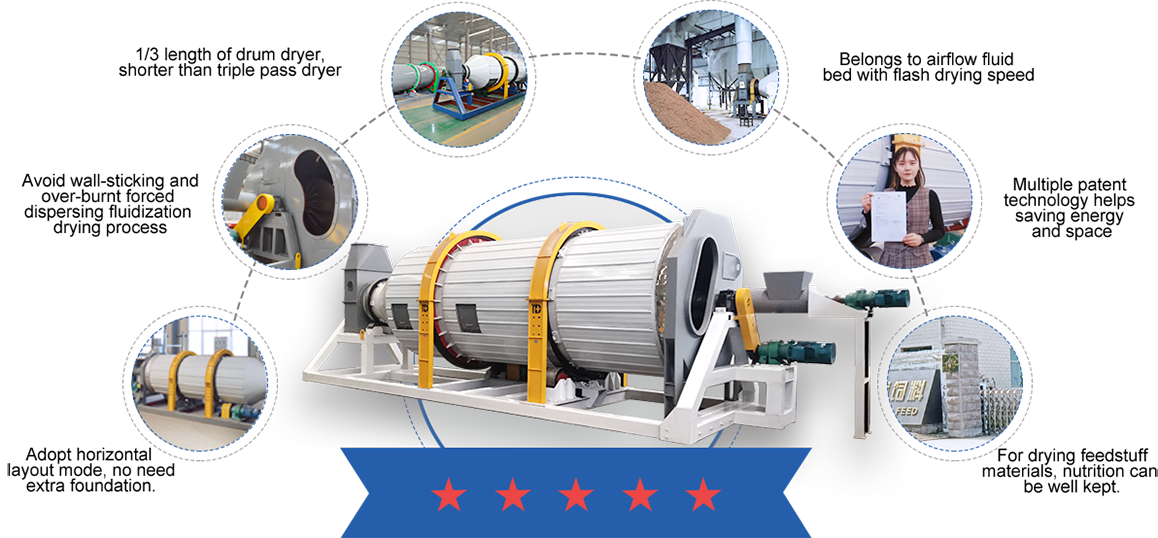

But fermented feed holds high moisture content. Once opened, it must be immediately used up or sealed. Otherwise, if there is no strict seal measurement and miscellaneous bacteria enters into feed , remaining feed will easily go bad. Spoiled feed is prone to cause diarrhea and low immunity problem for animals. Direct throw away or compositing will increase the cost of farming. At this moment, importance of drying process is obvious. But how to ensure quality of dry products has become a big problem for fermented feed processing. In order to solve this problem, Taeda® specially developed a new type of special E-style biomass dryer. Temperature rise of material during whole drying process will not exceed 30℃. No wall sticking no over burning. Final discharged dry products holds superior quality and nutrition loss is less. Dried fermented feed is lighter and easier to store.

Taeda E-style fermented feedstuff drying production line is especially suitable for drying, grinding and packing for fermented materials (like fermented spent grain, fermented bean pulp, fermented medicine dreg, solid fermented materials and mixed fermented materials) and high moisture feed materials (moisture ranges from 30% to 80%, like corn fiber, brewery grain, spent grain, furfural residue, soybean cake, peanut cake, soysauce residue, wheat bran, forage, insect shell and shrimp). Final product holds high nutrition content and good activity. On one hand, it can dry high moisture raw material into standard final product one step. On the other hand, materials can be dewatered first before entering dryer. We can also design multi level drying process for high end demands.

OSA fermented feedstuff drying line is suitable for drying various biomass fermented materials like brewery grain, spent grain, fermented bean pulp, spray corn husk, furfural residue, soybean sauce residue, pomace, cotton seed meal, soybean meal, cassava dregs and etc.

During whole drying process, temperature increase of raw material doesn't exceed 40℃. Both nutrition and beneficial bacterium in final products are kept well.

Bullet shape dryer body is set with three drying chambers, two groups of quick-open doors and one observation window. Whole dryer is featured in reasonable design, low malfunction rate, simple maintenance and easy operation. Professional steam can provide one step service including installation, guidance, running and trusteeship.

ba

Taeda E-style OSA dryer is mainly designed for high moisture biomass material drying. It is suitable for drying various fermented materials like spent grain, bean pulp, malt slag, furfural residue, soysauce residue, solid fermented material and spray corn husk. Whole drying process is characterized by low temperature increase, no nutrition loss and good final product quality.

| Model | Capacity(t/h) | Heat source | ||

| OSA-I | 0.8 | Biomass pellet, coal, coal gas, natural gas, diesel, wood and etc. | ||

| OSA-II | 1.2 | |||

| OSA-III | 2 | |||

| OSA-IV | 2.5 | |||

| OSA-V | 3.5 | |||

| OSA-VI | 4 | |||

| OSA-VII | 6 | |||

| Applicable materials | ||||

| Bran | Barley sugar residue | Barley fiber residue | Barley malt | Spray barley husk |

| Rice bran meal | Sorghum bran | Black wheat bran | Sorghum starch | Rice protein powder |

| Yellow vinasse | Spent grain | Brewery grain | DDS | DDGS |

| DWS | Buckwheat bran | Rice husk | BSG | Spray wheat bran |

| Wheat germ meal | Wheat sugar residue |

Wheat protein hydrolysate

|

Wheat fiber residue | Oat bran |

| Corn gluten meal | Corn germ | Corn sugar residue | Rapeseed dregs | Bean pulp |

| Bean curd | Tomato seed meal | Olive pulp | Olive pomace | Peanut pulp |

| Coconut dreg | Cassava dregs | Carrot residue | Potato dreg | Sucrose |

| Pomace | Straw | Forage grass | Herb residue | Ginger dregs |

| Meat meal | Bone meal | Protein meal | Blood meal | Fish meal |

General heat source

suitable for a variety of heat sources, not restricted by heat source

Low operating costs

Low energy consumption and low operating costs

Environmental protection

use various of dust collectors to meet local environmental standards

Quality control

High-precision process equipment, strict quality control

Support customization

customized equipment according to customer needs

Technical guidance

professional and technical personn-el on-site guidance operation

Automatic operation

automatic operation, simple operati-on and saving manpower