【Feeding size】:

【Feeding moisture】: 25% to 80%

【Capacity】: 0.1-10t/h

【Applicable material】: Cocopeat, palm silk bit, coconut slag, coffee ground, sugarcane bagasse and cassava dregs.

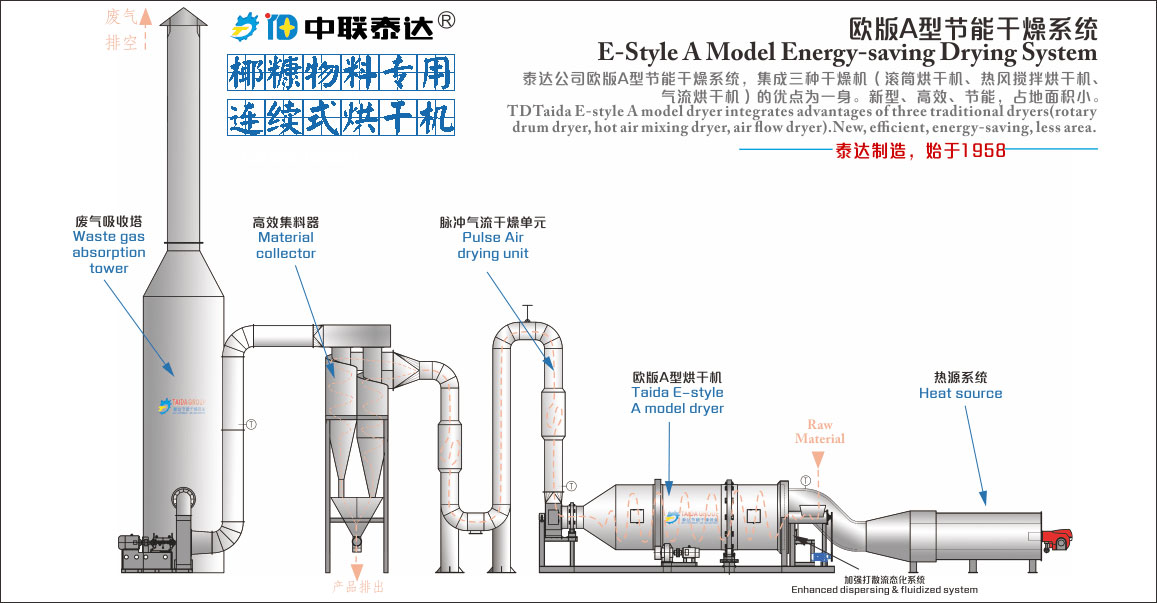

Taeda® cocopeat/cococoir dryer can be used for drying cocopeat, palm shredded pit, coffe ground, coconut slag, sugarcane bagasse, cassava dregs and similar materials. Its capacity ranges from 200kg to 10tph. Taeda cocopeat dryer is a kind of efficient drying system suitable for large capacity continuous drying work. It is featured in large capacity, small footprint, low energy consumption, stable running cost and high pertinence. Taeda takes features of cocopeat into consideration. Aimed at these features, we formulate special structure and modular. Multiple lifting plates installed on internal dispersing shaft can make sure that hybrid eddy current formed in inner drum and cocopeat present boiling status, which guarantees low temperature and strong drying capacity. After drying, dried cocopeat is about 10%. Final products can be used to make cat litter, biomass pellet and nutrient soil.

Compared with common dryer, Taeda new type cocopeat dryer holds many advantages like scientific optimization, shorter length, smaller heat dissipation area, cheap running cost and lower thermal loss. Its running cost is 15% lower than common dryer. In addition, heat source part of new cocopeat dryer takes production cost and drying effect into consideration. We can configure gas burner, biomass pellet burner, coal furnace and wood furnace based on customer's real situations so that lower running cost.

Taeda cocopeat dryer fully takes features of cocopeat coir into consideration like low added valve, with thermal value, small bulk density and high moisture content. It can reduce moisture of cocopeat to 10% one time. It is characterized by high efficiency, large capacity, stable operation, low energy consumption and low running cost.

Taeda cocopeat dryer adopts new drying concept, holds high mechanical level and uses centralized control, which makes sure good drying effect for cocopeat, longer service life and less quick wear parts.

Relying on scientific design, for same capacity, total length of OSA cocopeat dryer is only half of triple pass dryer and one third of common drum dryer. Therefore, OSA dryer holds small footprint and its heat radiating area is smaller than common dryer. With high energy utilization and low thermal loss, OSA dryer is more energy saving.

Whole drying system holds flexible configuration. We can configure dewatering equipment, feeder, crusher, heat source, conveying, dust collecting, elevation, cooler and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Model | Transmission motor power | Fan power | Dispersing power | Weight | Overall dimension(W*L*H) |

| TDJZⅠ | 4-4.5 KW | 7.5 KW | 3KW | 6.5t | 1.5×4.5×1.7m |

| TDJZ Ⅱ | 5.5 KW | 11 KW | 4KW | 9.5t | 1.6×5.5×2.0m |

| TDJZ Ⅲ | 7.5 KW | 15 KW | 5.5KW | 12.5t | 1.8×6.5×2.0m |

| TDJZ Ⅳ | 11 KW | 18.5 KW | 5.5KW | 18.5t | 2.4×8.5×2.5m |

| TDJZ Ⅴ | 15 KW | 22 KW | 5.5KW | 24t | 2.6×8.5×2.5m |

| TDJZ VI | 18.5 KW | 45 KW | 7.5KW | 32.2t | 3.0×10.5×3.0m |

| TDJZ VII | 22 KW | 75 KW | 11KW | 40t | 3.0×11×3.0m |

| Cocopeat moisture | Before drying: 40-85%, after drying:≤13 or at the customer's discretion | ||||

| Drying effect | Moisture can be reduced to 8-30% from 85%. | ||||