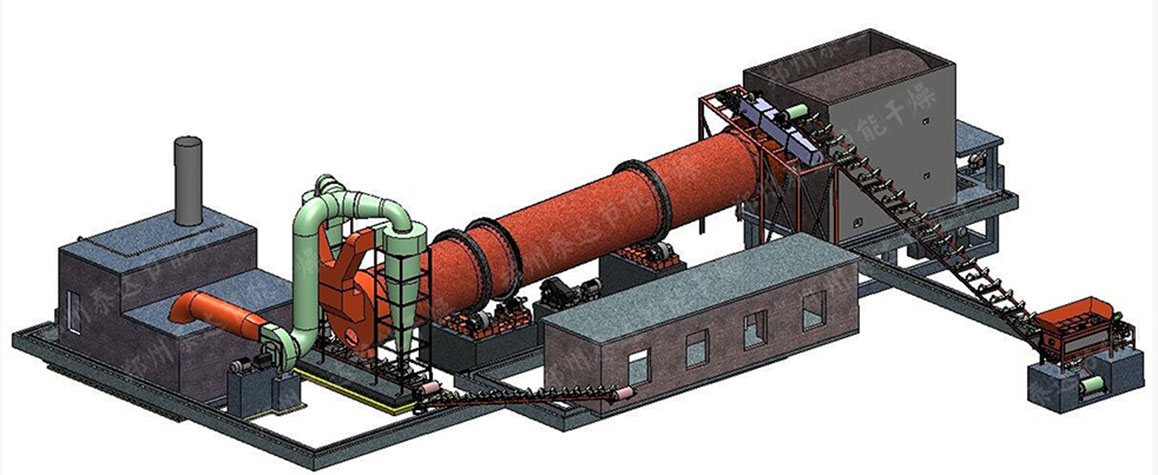

TDMT Series coal material drying upgrading system is a set of new equipment developed by our company especially for dealing with coal materials based on years’ application experience. It is mainly used to upgrade coal materials with 15% to 50% moisture content, like lignite, coal slurry, Mongolia coal, Indonesia coal, flotation fine coal, blending coal, filtered tail coal, middling coal and semi-coke. It holds high drying strength and thermal efficiency can reach to over 90%.

We fully take the properties of materials to be dried into consideration while designing TDMT system. Aimed the high moisture content feature, we do a special design for the internal structure which improves thermal efficiency and avoids over-dry phenomenon. TDMT drying system works under hypoxic condition. TDMT system is designed with explosion-proof modular, which guarantees safe and reliable performance. In order to meet demands of different customers, different markets, different environments, different materials property and different environmental protection standards, we do the most optimized configuration for TDMT system. At present, coal drying upgrading system has been developed to the sixth generation. Zhengzhou Taida holds more than 20 patents now. Diameter of drying equipment ranges from 1 m to 4.2m and length ranges from 15m to 38m. Daily input capacity of Taida dryer can reach to 100 to 3000 tons. Final moisture after drying can be reduced to about 10%, even lower. For raw materials with high moisture, TDMT system can avoid problems faced by traditional drying systems, like wall sticking and blocking. TDMT system is characterized by smooth running, reliable operation, good product quality and strong evaporation capacity, which completely solve a series technical difficulties during material drying process. Taida TDMT system has been put into operation in many coal enterprises at Yunan, Ningxia, Inner Mongolia, Shandong, Shanxi, Henan, Hebei, Anhui, Helongjiang, Jiangsu, Indonesia and has created considerable economic and social benefits.

As professional coal dryer manufacturer, Zonelion Taeda fully takes transportation convenience and installation time into consideration during fabrication. Installation speed of Taeda coal dryer increase by 30% than same capacity dryer from other suppliers. At present, it has been put into use in many enterpriese in Yunnan, Guizhou, Ningxia, Mongolia, Shandong, Shanxi, Henan, Hebei, Anhui, Heilongjiang, Jiangxu and Indonesia. Taeda coal dryer has created considerable social and economic profits.

New feeding and discharging device can prevent clogging, uneven and discontinuous feeding and material backing phenomenon. Dust removal burden is reduced. Dryer adopts center-aligning riding wheel makes sure linear contact between riding wheel and roller ring so that reduce equipment abrasion and power consumption.

Taeda coal dryer is featured in high thermal efficiency, low energy consumption, high over load resistance, large capacity, less fuel consumption and low drying cost. It adopts fair current drying mode. Flue gas and wet materials enter dryer from same end. Strong evaporation capacity is achieved by high temperature flue gas. Meanwhile, outlet temperature of dryer is low and thermal efficiency is high.

In Taeda coal dryer, materials can form stable and whole-section material curtain, which makes sufficient mass and heat exchanging. New internal structure strengthens cleaning and heat conduction function to scattered materials. Negative pressure hypoxic environment in the dryer. Taeda coal dryer holds better adaptability to material moisture and stickiness.

| Model | Size | Input capacity (t/h) | Evaporation capacity (t/h) | Motor power (Kw) | Occupation area |

| TDMT1616 | 1.6×16m | 10-15 | 1.5-2 | 68 | 30×6 |

| TDMT2018 | 2.0×18m | 25-30 | 3-5 | 126 | 35×7 |

| TDMT2418 | 2.4×18m | 40-60 | 7-8 | 245 | 50×12 |

| TDMT3020 | 3.0×20m | 70-90 | 11-13 | 358 | 50×15 |

| TDMT3425 | 3.4×25m | 100-150 | 16-20 | 520 | 60×15 |

| TDMT4036 | 4.0×36m | 130-200 | 28-40 | 635 | 70×15 |

| TDMT4238 | 4.2×38m | 350-450 | 45-50 | 712 | 74×16 |