【Feeding size】:

【Feeding moisture】: 35-85%

【Application range】: Applied for feedstuff, agriculture, herbal medicine, medicine, forage and environmental protection industry.

Taeda® cassava dregs dryer can be used to dry various cassava dregs, sweet potato residues, purple potato residue, potato residues and other similar starch residues materials. It is a drying machine designed based on OSA E-style biomass dryer for cassava materials. We adopt European good experience and technology during designing process. Taeda cassava dregs dryer is a kind of new drying equipment featured in high efficinecy, energy conservation and low emission. Customers can make use of Taeda cassava dregs dryer to realize feedstuff application and comprehensive utilization for cassava dregs. According to material type and process, dried products can be used as organic fertilizer and feedstuff.

Cassava dregs is by product after starch extraction. The reason why final products from Taeda cassava dregs dryer hold superior effect is that Taeda redesign drying system based on features of cassava dregs, sweet potato residues, purple potato residue, potato residues and starch residues materials. Taeda puts customers's needs at first place and takes both material feature and regional dfference into consideration. Common cassava in China ARE sweet potato and potato. In southeast China and Africa, commonly seen is cassava. There is crude fiber, moisture, starch and protein in cassava dregs. We mainly aimes at provides comprehensive cassava dregs utilization methods which takes dryer as core process (make use cassava dregs to produce fertilizer and feedstuff). Fertilizer made from cassava dregs is always used as soil matrix and organic fertilizer. For feedstuff production, there are two technical routes. One is to directly dry and make feedstuff and the other one is to make feedstuff after fermentation and degradation. Cassava dregs dryer is classified into 7 models.

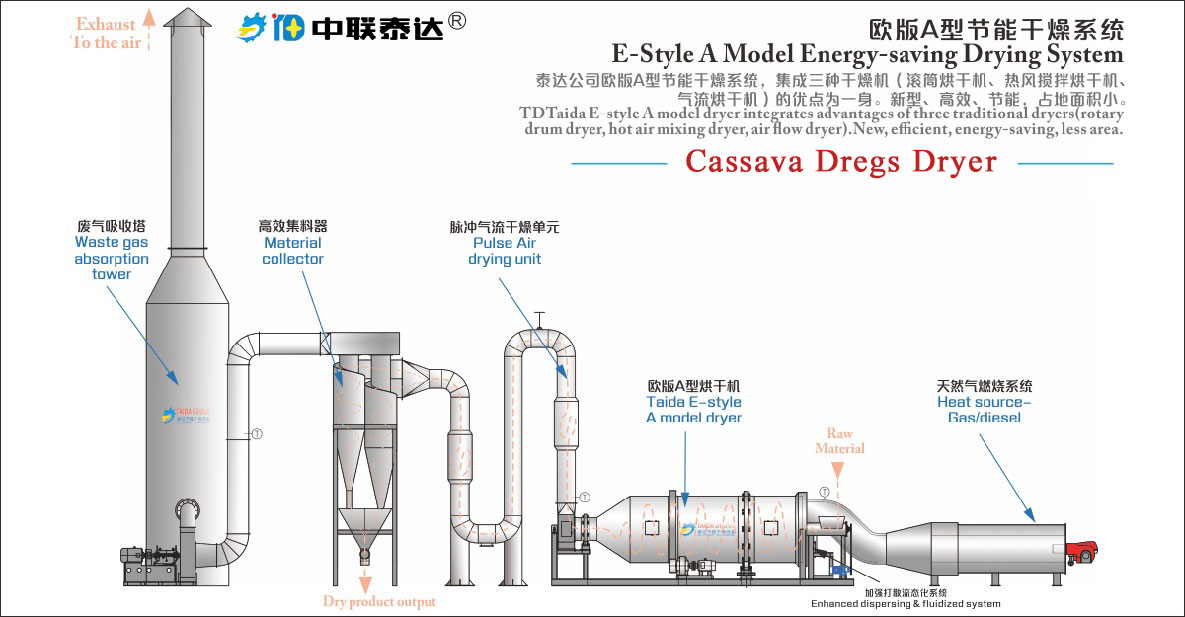

Taeda cassava dregs dryer mainly contains heat source, feeder, dryer, discharger, ID fan and electrical control cabinet. Dewatered cassava dregs enter dryer and fully contact with hot air, which speeds up heat and mass transfer. Process parameter of production line, technical parameter and structure are chosen and designed based on careful research on cassava materials and real pilot run. During solution design, cassava dregs' features like high moisture content, high protein content and viscosity are fully taken into consideration. Aimed at these features, Taeda carries out a series technical and process to solve so that to guarantee good drying effect.

Taeda cassava dregs dryer solve series difficulties in face of cassava material drying like wall sticking, lump forming and blocking and eliminate customers' concern. Taeda cassava dregs dryer can reduce moisture of cassava materials to below than 12% one time. Configured with special temperature regulating, lifting plate, leading plate and dispersing device, Taeda cassava dregs dryer can effectively avoid wall sticking and blocking situation. Final products from Taeda cassava dregs dryer is characterized by gold color and good quality. Owing to energy conservation and environment protection performance, Taeda cassava dregs dryer enjoys great popularity at home and abroad.

Zonelion Taeda cassava dregs dryer is a kind of efficient drying system specially designed for drying various cassava dregs, sweet potato residues, purple potato residue, potato residues and other similar materials.

High speed dispersing system is installed at cross section of dryer. Match with proper air accelerator and vortex generation device, there will be boiling material curtain formed. Efficient heat exchanging helps evaporation and temperature decrease so that avoid wall sticking and over burning phenomenon.

Relying on scientific design, for same capacity, total length of OSA tuber crop dregs dryer is only half of triple pass dryer and one third of common drum dryer. Therefore, OSA dryer holds small footprint and its heat radiating area is smaller than common dryer. With high energy utilization and low thermal loss, OSA dryer is more energy saving.

Whole drying system holds flexible configuration. We can configure dewatering equipment, feeder, crusher, heat source, conveying, dust collecting, elevation, cooler and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Model | Transmission motor power | Fan power | Dispersing power | Weight | Overall dimension(W*L*H) |

| TDJZⅠ | 4-4.5 KW | 7.5 KW | 3KW | 6.5t | 1.5×4.5×1.7m |

| TDJZⅡ | 5.5 KW | 11 KW | 4KW | 9.5t | 1.6×5.5×2.0m |

| TDJZⅢ | 7.5 KW | 15 KW | 5.5KW | 12.5t | 1.8×6.5×2.0m |

| TDJZⅣ | 11 KW | 18.5 KW | 5.5KW | 18.5t | 2.4×8.5×2.5m |

| TDJZⅤ | 15 KW | 22 KW | 5.5KW | 24t | 2.6×8.5×2.5m |

| TDJZⅤI | 18.5 KW | 45 KW | 7.5KW | 32.2t | 3.0×10.5×3.0m |

| TDJZⅤII | 22 KW | 75 KW | 11KW | 40t | 3.0×11×3.0m |

| Cassava dregs moisture | Before drying: 35-85%; after drying: ≤13% | ||||

| Output capacity | 1t/h to 10t/h; depends on raw material and moisture; dried products can be used for fertilizer and feedstuff. | ||||