【Capacity】:

【Initial moisture】: 50-60%

【Final moisture】: 10-15%

Cassava is a kind of plant with cylindrical tuber and is native to Brazil. Now it is widely cultivated in tropical regions around the world. The tuber of cassava is rich in starch, therefore cassava is one of the raw materials for industrial starch production.

Cassava Chips tablets Dryer is suitable for drying fresh chipped cassava to cassava dry tablets used for starch raw material. It is widely used for material storage in starch factories and solve material supply conflict slack seasons. It is a kind of good equipment for improving equipment utilization efficiency and enterprises competitiveness. If cassava starch production enterprieses only rely on fresh cassava for starch production. Production time is short and equipment utilization efficiency is low. Fixed cost of product is high. Places like China (Fujian, Taiwan, Guangdong, Hainan, Guangxi, Guizhou and Yunnan), Southeast Asian countries (such as Vietnam, Thailand, Indonesia, etc.), and African countries are rich in cassava. Taeda Cassava Chips tablets Dryer is used to make harvested fresh cassava into dry Tablets, which can effectively use advantages of regions and raw materials so that to ensure that they can be supplied to starch production plants as raw materials any time. In addition, because of its special properties (such as low viscosity, transparent paste, etc.), cassava dry tablets starch has its targeted users and application fields in the market.

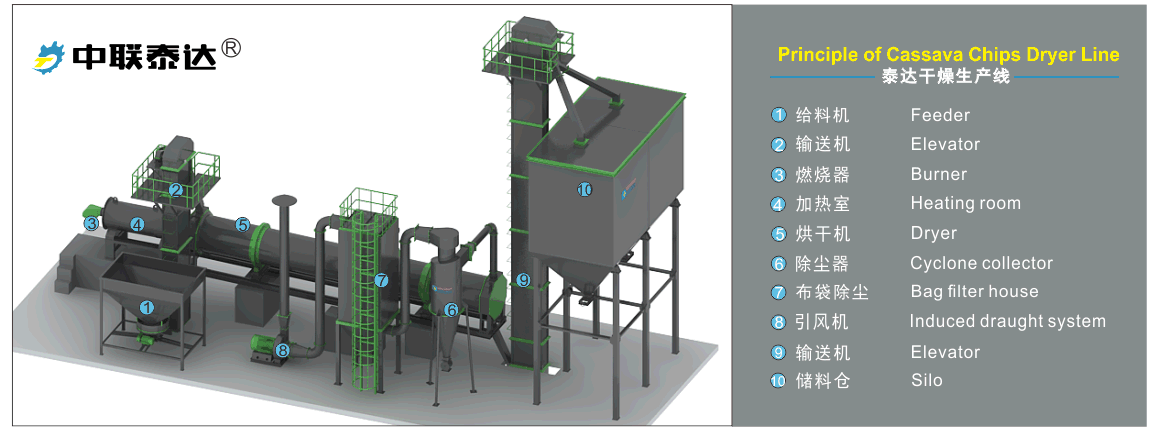

Taeda Cassava Chips tablets Dryer is a kind of continuous dryer which regards hot air as media. Both capacity and efficiency are higher than natural sun drying and drying room. Meanwhile, investment cost of Taeda cassava chips tablets dryer is lower than mesh belt dryer. Therefore, it is a kind of ideal industrial drying equipment worth investment.

Friendly reminder: This set of Taeda® cassava chips tablets drying equipment is not suitable for production of cassava chips used for food and it is not suitable for production of snacks.

Modular dust collecting and purifying heat recycling configuration, safe and protect environmental. Relatively, running cost of Taeda cassava chips dryer is lower.

There are various inlet temperatures. This machine can make moisture of final product reach to standard for long-term storage which provides convenience for next process.

There is a whole set of equipment which holds 10 to 200t/h output capacity. We can also customize drying machine according to customer’s demands.

After times' upgrading and improvement, no matter in terms of energy consumption or capacity, Taeda Cassava Chips tablets Dryer holds better performance than common rotary drum dryer.

| Item |

Gradient (%) |

Rotational speedr/min) | Inlet air temperature(℃) | Capacity (t/h) | Power(kw) |

| MGT600 | 3-5 | 3-8 | ≤850 | Different Materials Different Capacity. | 3 |

| MGT800 | 3-5 | 3-8 | ≤850 | 4 | |

| MGT1000 | 3-5 | 3-8 | ≤850 | 5.5 | |

| MGT1200 | 3-5 | 3-8 | ≤850 | 11 | |

| MGT1500 | 3-5 | 3-8 | ≤850 | 15 | |

| MGT1800 | 3-5 | 3-8 | ≤850 | 18.5 | |

| MGT2000 | 3-5 | 3-8 | ≤850 | 22 | |

| MGT2200 | 3-5 | 3-8 | ≤850 | 30 | |

| MGT2400 | 3-5 | 3-8 | ≤850 | 37 | |

| MGT2600 | 3-5 | 3-8 | ≤850 | 40 | |

| MGT2800 | 3-5 | 3-8 | ≤850 | 55 | |

| MGT3000 | 3-5 | 3-8 | ≤850 | 75 | |

| MGT3200 | 3-5 | 3-8 | ≤850 | 90 | |

| MGT3400 | 3-5 | 3-8 | ≤850 | 110 | |

| MGT3600 | 3-5 | 3-8 | ≤850 | 150 | |

| MGT4000 | 3-5 | 3-8 | ≤850 | 190 | |

| MGT4200 | 3-5 | 3-8 | ≤850 | 200 | |

| MGT4500 | 3-5 | 3-8 | ≤850 | 260 |