Capacity: 1-3t/h

Working mode: 24hours per day

Products:carbon black powder, carbon black granules

Carbon black is a kind of fine and loose black powder without certain shape. Carbon black holds very large superficial area. Carbon black is produced by uncompleted combustion of materials containing carbon like coal, natural gas, heavy oil and fuel oil while air is not sufficient. Generally, carbon black produced from natural gas is called “gas carbon black; Carbon black produced from oil is called “light black”; carbon black produced from acetylene is called “acetylene black”. There are also other type’s carbon blacks like “trough black” and “furnace black”. According to property of carbon black property, carbon black can also be classified into reinforcing carbon black, electricity conduction carbon black and abrasion-resistant carbon black.

Main ingredients in carbon black is carbon. It holds strong rubber reinforcing, dyeing, electricity conducting, anti-static and ultraviolet absorption function. As a kind of functional material, carbon black can endow special characteristics to other products or items. Therefore, carbon black plays an unreplaceable role in many fields, such as plastics, chemical fiber, printing ink, painting, electrical components, leather, dry batteries and etc. Meanwhile, as a kind of high-purity carbon material, carbon black can also be applied for metallurgy and carbonaceous material industries.

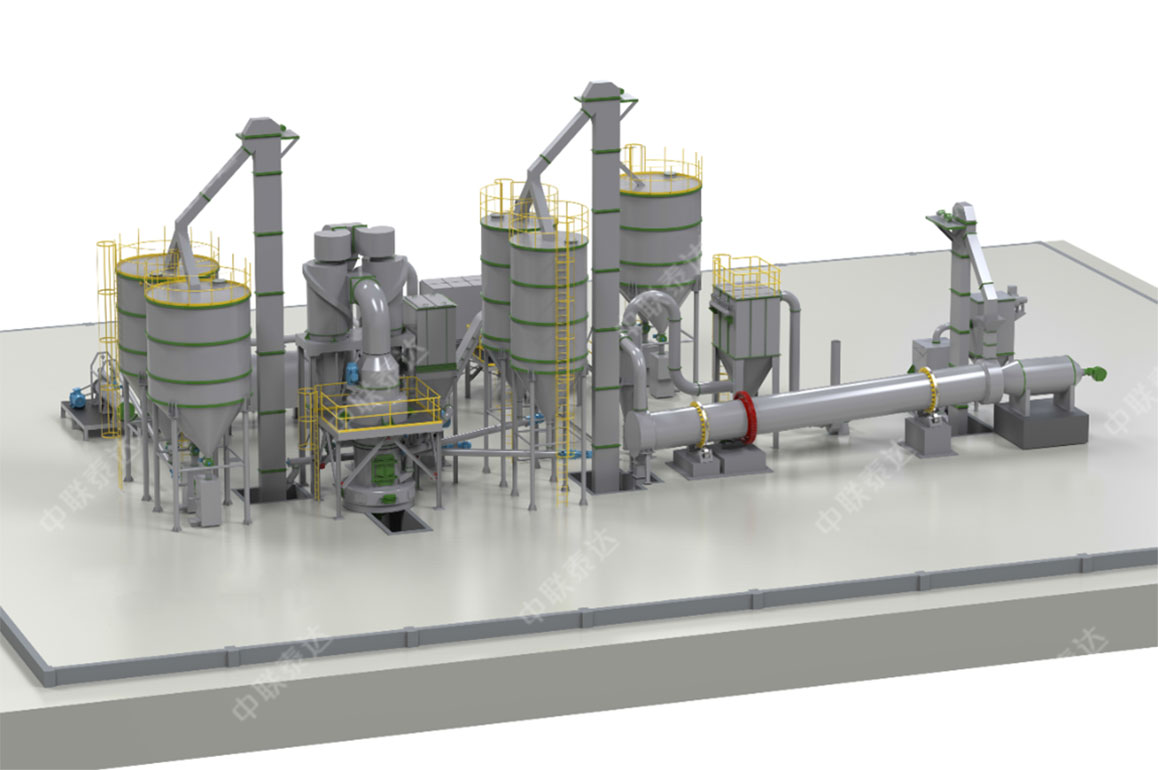

In carbon black industries, there are several products most popular like 325-mesh carbon black powder, 1250-mesh carbon black powder and 1-3mm globular carbon black pellets produced by set pelleting/granulating method. Owing to low bulk density and easily flying feature, it is not easy to transport for carbon black. Therefore, globular carbon black pellets produced by wet method granulating method enjoys more and more market. Based on mature micro powder grinding and wet pin-mix granulating/pelleting technology, ZONELION TAEDA makes special innovation for the carbon black production line. After years’ experience and market accumulation, ZONELION TAEDA Wet Method Carbon Black Production line is widely praised at home and abroad.

Taeda carbon black powder/granulating production line can be used to process various carbon black materials from different industries like tyre and gas.

Taeda carbon black powder/granulating production line Carbon Black Powder/Granulating Line can produce more output products with less energy consumption amount. Customer can choose suitable model ba

With reasonable structural design, all equipment in Taeda carbon black powder/granulating production line holds lowwer malfunction rate and longer serivce life. Operators can grasp operation skills in short time.

Final carbon black granules are with homogenous size, The intermediate product is an ultrafine black carbon powder. Customer can choose carbon black powder or carbon black granules as final product according to market needs.

This part mainly consists of feeding system, heat source system, drying system and dust collecting system and conveying system.

This part mainly consists of micro powder grinding mill, classifier, cyclone collector, sound-proof room and dust collector.

This part mainly consists of feeding system, heat source system, drying system and dust collecting system and conveying system.

| Carbon black production line consists of three main sections | ||||

| Project section | Raw Material Dryer | Grinding Mill | Granulating/Pelletizing Machine | Granules Dryer |

| Machine model | MGT 1000-1500 | TGM80-100 | 8D400-600 | TDICA1.0-1.8 |

| Auxiliary machine | In order to make sure smooth running of whole system, besides above major equipment, we can also configure you necessary auxiliary equipment, like bucket elevator, conveyor, silo, packing machine, screen machine and etc. | |||

| Notes: Please don’t hesitate to contact us for technical details and equipment configuration proposal. | ||||

General heat source

suitable for a variety of heat sources, not restricted by heat source

Low operating costs

Low energy consumption and low operating costs

Environmental protection

use various of dust collectors to meet local environmental standards

Quality control

High-precision process equipment, strict quality control

Support customization

customized equipment according to customer needs

Technical guidance

professional and technical personn-el on-site guidance operation

Automatic operation

automatic operation, simple operati-on and saving manpower