【Feeding size】:

【Feeding moisture】: 35-85%

【Application range】: Suitable for industries like feedstuff, agriculture, bean product factory, soybean milk factory, aquatic product, animal husbandry and environment protection.

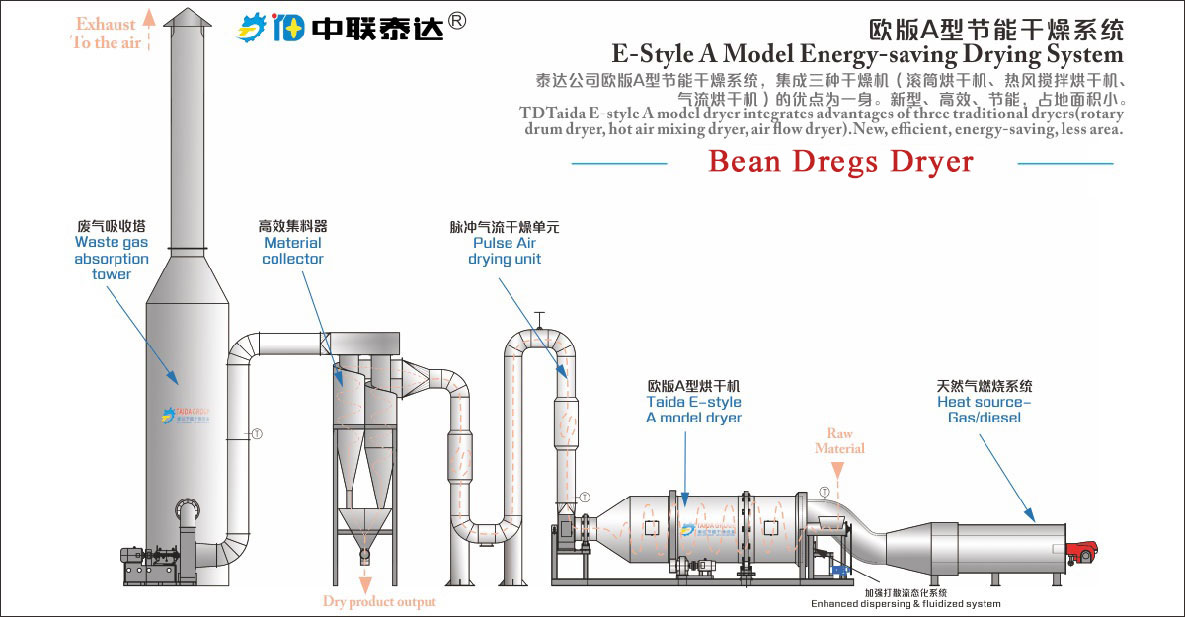

Taeda® bean dregs dryer can be used for drying bean dregs, fermented bean dregs, bean curd residue, soybean milk residue, soybean dregs, bean fiber and other similar feedstuff materials from soybean milk factory, bean product factory and soy milk factory. Meanwhile, Taeda bean dregs dryer can also be used as combined primary drying machine for cat litter production line. Energy consumption and energy consumption of Taeda bean dregs dryer is generally 10% to 15% lower than common drum dryer. Capacity of Taeda bean dregs dryer is 10% to 15% higher than common dryer. Therefore, running cost is saved. Under this condition, this kind of dryer is suitable for drying bean dregs material with low market sold price.

Taeda bean dregs dryer is divided into 7 models based on capacity range. Output capacity ranges from 0.5 to 5tph. Different from steam tube bundle dryer and small batch dryer, it is featured in large capacity, small footprint, low energy consumption and stable running performance. It is specially designed for processing difficulties of bean dregs(bean curd residues) like internal bound water, oil content and viscosity.

Working principle of new bean dregs dryer:

In order to save running cost, bean dregs will be dewatered by heavy pressure. Under the premise that protein will not be lost, remove moisture on surface. Then, dewatered bean dregs enter dryer. Under the function of material pushing plate and dry hot air, bean dregs will move back and forth along with the direction opposite to fresh hot air. The movement passage is long and temperature is low. Materials move slowly. It is a downstream drying process inner drum and temperature of output material is only 40℃. Thermal energy is fully used and bean dregs are heated uniformly during whole drying process. Therefore, final product from Taeda bean dregs dryer is featured in golden color, no over-burning and low energy consumption.

Taeda bean dregs dryer is especially designed for drying bean dregs, soybean meal, fermented bean dregs, bean curd residue, soybean pulp and bean fiber materials.It can reduce materials' moisture to 10% one step. Meanwhile, it can also work with dewatering machine so that to reach higher capacity and lower cost.

There is high speed dispersing system set on cross section of dryer. Matched with proper air accelerator and vortex device, boiling material curtain will form, which makes heat exchanging, evaporation and temperature decrease efficient. It is suitable for drying fermented soybean meal in particular.

Relying on scientific design, for same capacity, total length of OSA bean dregs dryer is only half of triple pass dryer and one third of common drum dryer. Therefore, OSA dryer holds small footprint and its heat radiating area is smaller than common dryer. With high energy utilization and low thermal loss, OSA dryer is more energy saving.

Whole drying system holds flexible configuration. We can configure dewatering equipment, feeder, crusher, heat source, conveying, dust collecting, elevation, cooler and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Model | Transmission motor power | Fan power | Dispersing power | Weight | Overall dimension(W*L*H) |

| TDJZⅠ | 4-4.5 KW | 7.5 KW | 3KW | 6.5t | 1.5×4.5×1.7m |

| TDJZⅡ | 5.5 KW | 11 KW | 4KW | 9.5t | 1.6×5.5×2.0m |

| TDJZⅢ | 7.5 KW | 15 KW | 5.5KW | 12.5t | 1.8×6.5×2.0m |

| TDJZⅣ | 11 KW | 18.5 KW | 5.5KW | 18.5t | 2.4×8.5×2.5m |

| TDJZⅤ | 15 KW | 22 KW | 5.5KW | 24t | 2.6×8.5×2.5m |

| TDJZⅤI | 18.5 KW | 45 KW | 7.5KW | 32.2t | 3.0×10.5×3.0m |

| TDJZⅤII | 22 KW | 75 KW | 11KW | 40t | 3.0×11×3.0m |

| Bean dregs/pulp moisture | Before drying: 25-85%, after drying:≤13 | ||||

| Output capacity | 0.5-5t/h, depends on raw material and moisture content. | ||||