【Raw materials】: new carbon, coal-ba

【Particle size】: columnar, particle

【Working principle】: continuous, steam activation

【Working temperature】: 950-1000℃

TDAGK activation furnace kiln is a very important equipment for active carbon production process. It is widely applied to activation of charcoal carbon(produced from sawdust, coconut shell,bargasse, rice husk, straw, hezelnut shell,nut shell, fruit shell) and coal-based carbon. It adopts vapor as activation medium. Under high temperature environmen, steam can fully contact with charcoal to be activated. Final active carbon produced by TDAKG activation furnace holds superior activation property and can be widely applied to water purification and beneificiation industry.

Based on ignition loss amount and heat supply mode, it is divided into external heating supplying type and self heating type. Self-heating type furnace holds larger ignition loss, but no need extra heat source and operation is easier. Besides activation furnace, we can also provide relevant auxiliary equipment.

Taida activation furnace set wth common control cabinet or PLC control system, holds high automation level. Our professional team will do training for operators so that to help customer grasp operation skills fast.

Taeda Activation furnace is a kind of of continous equipment where new carbon is constantly activated. Final products will be discharged from cooling port. Index like Methylene blue adsorption value and iodine value are up to standard.

Taida Activation furnace adopts full steam activation atmosphere, which improves activation effect. Taeda activation furnace adopts superior fabrication texture featured in high-temperature resistance and anti-corrosion. As professional manufacturer, we can give guarantee to the regeneration kiln we provide.

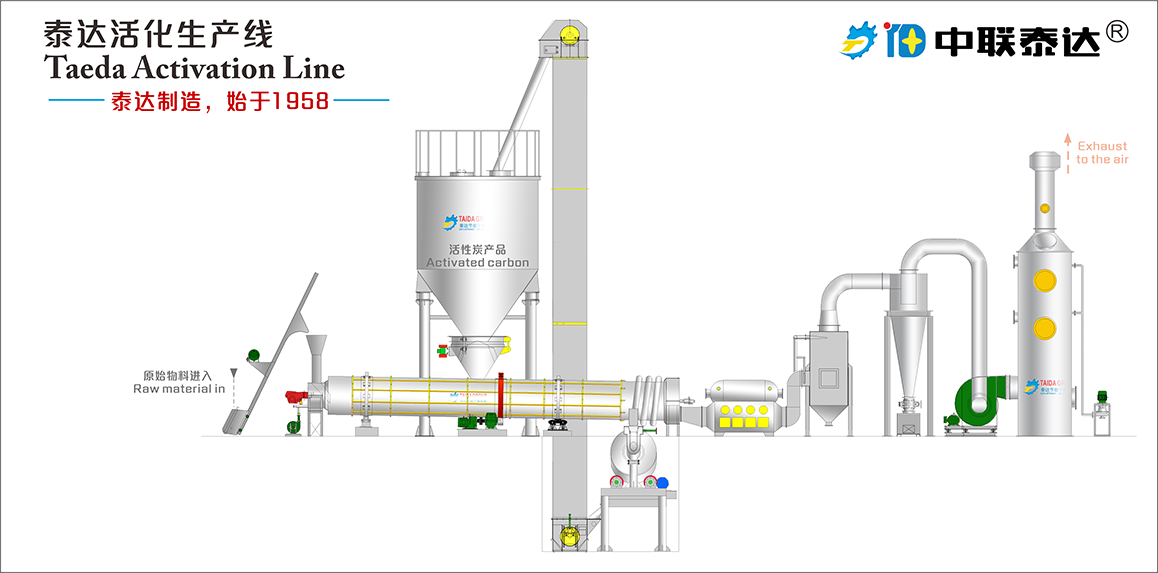

Scientific structural design makes longer service life. We can configure customers with feeding equipment, cooling equipment, exhaust heat utilization equipment, dust collecting equipment and purification equipment. Whole system holds reasonable design.

| Model |

Input Capacity (kg/h) |

Power | Driving motor | Overal Dimensions (L×W×H) |

| TDAGK0.6 | 300-500 | 5.5 | Frequency control | 10*1.1*1.2 |

| TDAGK0.8 | 400-600 | 7.5 | 12*1.3*1.5 | |

| TDAGK1.0 | 500-800 | 11 | 12*1.5*1.7 | |

| TDAGK1.2 | 700-1200 | 15 | 14*1.7*1.8 | |

| TDAGK1.5 | 1000-1500 | 18.5 | 14*2*2.2 | |

| TDAGK1.6 | 1500-1800 | 22 | 17*2.1*2.2 | |

| TDAGK1.8 | 1800-2500 | 30 | 20*2.3*2.5 | |

| TDAGK2.0 | 2700-3200 | 37 | 20*2.5*2.7 | |

| TDAGK2.2 | 3200-4000 | 45 | 20*2.7*2.8 | |

| TDAGK2.5 | 4000-5000 | 55 | 20*3*3.1 | |

| TDAGK3.0 | 5000-6000 | 75 | 20*3.5*3.8 |