【Feeding size】:

【Feeding moisture】: 4% to 25%

【Capacity】: 0.5 to 200tph

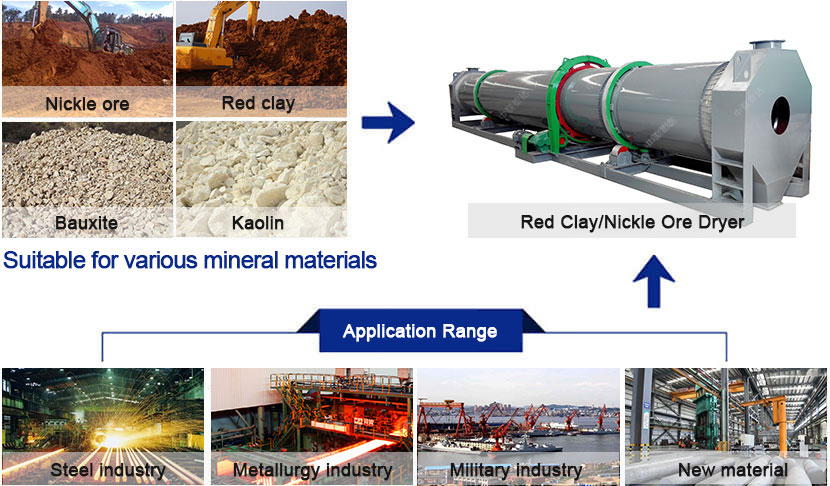

【Applicable material】: Laterite, red clay, nickle ore, bauxite ore, bentonite and other high moisture ore materials.

Taeda laterite nickle ore dryer can be used to dry ore materials with 25% internal and external moisture like laterite, red clay, nickle ore, and bauxite ore. It is suitable for large scale continuous drying work. Aimed at bound water and easy caking features, Taeda team makes special design for gauranteening good drying effect. At present, Taeda laterite nickle ore dryer has been put into application in nickle mine enterprises and created considerable economic profits. Taeda company can also provide nickle ore calcining roasting production line for further improving product quality. Please feel free to contact us for details.

Taeda laterite nickle ore dryer solves easy caking problem of red clay/laterite and changes material plate structure of common single drum dryer. It adopts compound self-cleaning device which greatly expands application range of single drum dryer and final product holds good quality. Free moisture can be reduced to lower than 1% and final product holds even particle size. Besides laterite, red clay, nickle ore and bauxite ore, Taeda laterite nickle dryer also enjoys great popularity among customers for drying similar soil, mineral and sand stone materials.

Aimed at free moisture and bound moisture contained in laterite nickle ore, Taeda does series of rational design need for similar material drying. Taeda rotary drum dryer can reduce moisture of red clay/laterite materials to lower than 1% from 25% one time. Whole system holds large capacity, low energy consumption and less investment cost.

Taeda laterite nickle ore dryer adopts automatic centralized control mode which makes it run continuously. Laterite/red clay fully contacts with hot air which makes sure good drying effect and strong drying ability. Drying task can be finished in short time and whole drying process is done in a smooth procedure. Superior manufacturing texture guarantees longer service life and low malfunction rate.

Taeda laterite nickle ore dryer is characterized by wide application range, high production capacity, strong evapration ability, simple structure, small footprint, low investment/running/maintenance cost. Heat source system can match with coal gasifier, coal hot air furnace, pellet burner, diesel burner and natural gas burner to produce proper hot air.

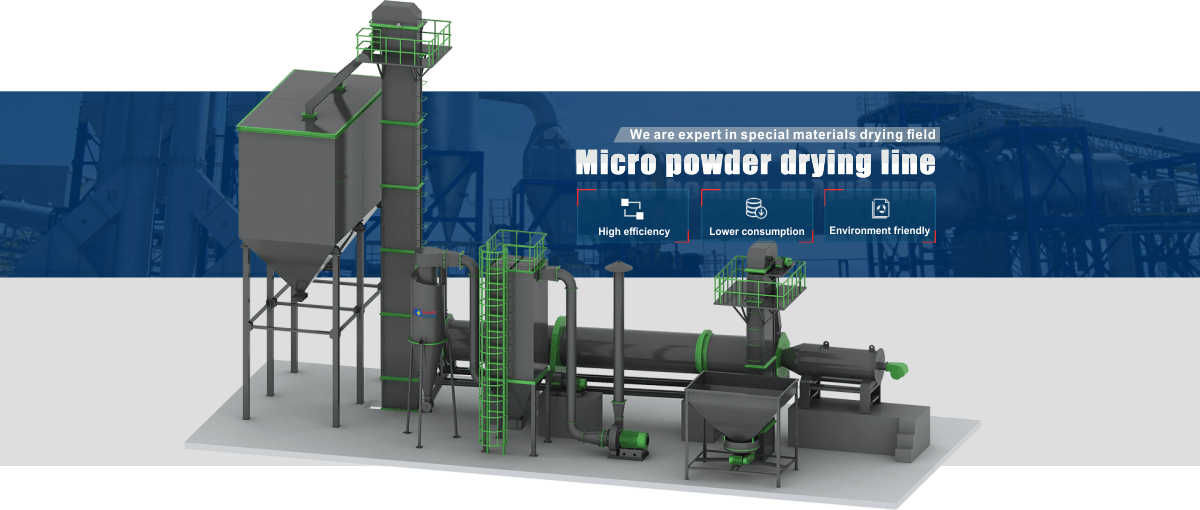

Whole drying system holds flexible configuration. We can configure dewatering equipment, feeder, crusher, heat source, conveying, dust collecting, elevation, cooler and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Item |

Gradient (%) |

Rotational speedr/min) | Inlet air temperature(℃) | Capacity (t/h) | Power(kw) |

| MGT600 | 3-5 | 3-8 | ≤850 | Different Materials Different Capacity. | 3 |

| MGT800 | 3-5 | 3-8 | ≤850 | 4 | |

| MGT1000 | 3-5 | 3-8 | ≤850 | 5.5 | |

| MGT1200 | 3-5 | 3-8 | ≤850 | 11 | |

| MGT1500 | 3-5 | 3-8 | ≤850 | 15 | |

| MGT1800 | 3-5 | 3-8 | ≤850 | 18.5 | |

| MGT2000 | 3-5 | 3-8 | ≤850 | 22 | |

| MGT2200 | 3-5 | 3-8 | ≤850 | 30 | |

| MGT2400 | 3-5 | 3-8 | ≤850 | 37 | |

| MGT2600 | 3-5 | 3-8 | ≤850 | 40 | |

| MGT2800 | 3-5 | 3-8 | ≤850 | 55 | |

| MGT3000 | 3-5 | 3-8 | ≤850 | 75 | |

| MGT3200 | 3-5 | 3-8 | ≤850 | 90 | |

| MGT3400 | 3-5 | 3-8 | ≤850 | 110 | |

| MGT3600 | 3-5 | 3-8 | ≤850 | 150 | |

| MGT4000 | 3-5 | 3-8 | ≤850 | 190 | |

| MGT4200 | 3-5 | 3-8 | ≤850 | 200 | |

| MGT4500 | 3-5 | 3-8 | ≤850 | 260 |