Introduction

Generally, water consumption in dyeing mill, textile mill and electroplate factory are very large. There are always set with waste water treatment units in these places, therefore large quantity of sludge will be produced every day. Based on scale and feature, different enterprises adopt different disposal methods, like frame plate filtering, screw dewatering, belt dewatering and centrifuge dewatering. Moisture of some filter cake from frame plate filter is lower than 60%. Moisture of filter cake from other dewatering process is always higher than 85%. It will cost much expense for enterprises to sludge solid wastes. Also, there always be secondary pollution caused to road. Correspondingly, it becomes new demand to realize harmless, drying and amount reduction aim. At present, major technical process are:

① reduce amount by drying; ②make ceramsite ball after calcining; ③incineration;④carbonize and burn as fuel;⑤fermentation and make compost. This article focuses on discussing amount reduction by drying process. Traditional technology and equipment is rotary drum dryer. Taking MED series dryer as example, it will need one φ0.8×8m or larger dryer to deal with 1t wet sludge per hour. Rotary drum dryer occupies large area, cause serious noise and consumes more energy. Along with more and stricter environmental protection regulation, low-temperature mesh belt dryer and heat pump dehumidification technology become hot topic in sludge drying industry. But, owing to high investment cost and low capacity, these two kinds dryer cannot meet market demands.

Most important is that if you choose manufacturer and dryer wrongly, you will have to face many problems like wall sticking, bad drying effect, pollution and high energy consumption.

OSC-AST Air Swept Dryer, display talents in Dewatered Sludge Drying

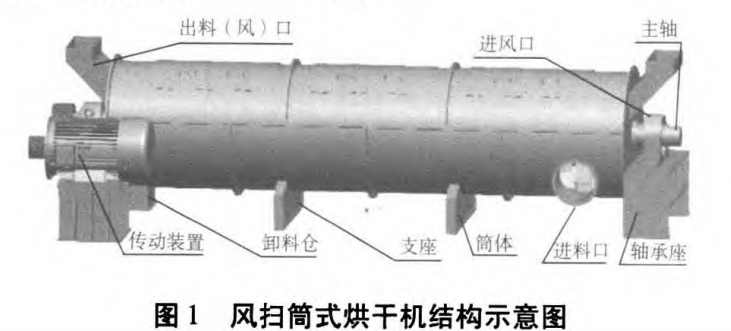

Under this premise, OSC-AST dryer holds very good technical advantages. OSC-AST Dryer is patent produced developed by Taeda and we also call it Air Swept Rotary Wing Dryer which is a new drying system with high efficiency and low energy consumption. It can be used to dry sticky materials which cannot be dried by common dryer. It integrates drying, crushing and dispersing function into a whole. It is characterized by fast drying speed, and good drying effect. What’s more, residence time of raw materials can be adjusted.

Working principle of OSC-AST dryer: drying medium enters dryer through air inlet. Sticky materials are fed into dryer inside through feeding device. After dispersing, stirring and heat exchanging, raw materials fully contact with heat medium and discharged out from air outlet with hot air.

In terms of working principle: after being sent to OSC-AST dryer by screw pump, shaftless screw or belt conveyor, sticky materials present floating state under function of dispersing, crushing and blade function. Materials can fully exchange heat. While reaching good drying effect, small body and small occupation area can also be guaranteed.

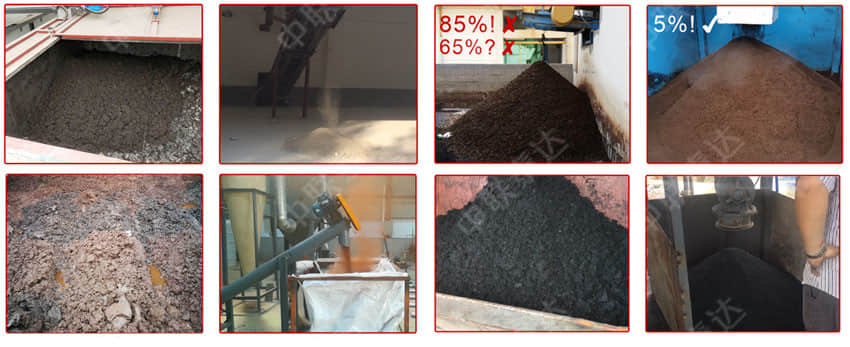

Material Comparison Before and After OSC-AST Drying

In terms of drying effect, OSC-AST air swept dryer can make it true to make compost by dried sludge. Final moisture after AST dryer can reach 5% or lower easily. Here attach some materials’ picture before and after drying.

If you or your dewatered sludge is in need of our new type drying equipment, your can contact us anytime for details.

Copy reserved, reprint is prohibited.

Relative news