Zonelion Taeda® metal powder shaving/scrap dryer is a kind of drying system developed mainly for metal shaving/chip/scrap material drying. It is featured in wide application range, simple operation and low running cost. Taeda metal shaving dryer is very suitable for small/large-medium sized customers.

Wet metal shavings enter dryer through feeding end. In dryer drum, it will mix with hot air. During moving in the 8-30-m length dryer drum, moisture will be evaporated continuously. Final standard dry products will be discharged out of dryer. It can be applied in metal recycling, renewable resources, waste cable wire recycling, circuit board crushing reycling and can recycling industries. Taeda metal shaving dryer makes it come true to dispose metal shaving harmlessly and recycle renewabe metal shavings so that to carry out sustainable economy development and avoid secondary pollution.

Taeda me

Taeda me

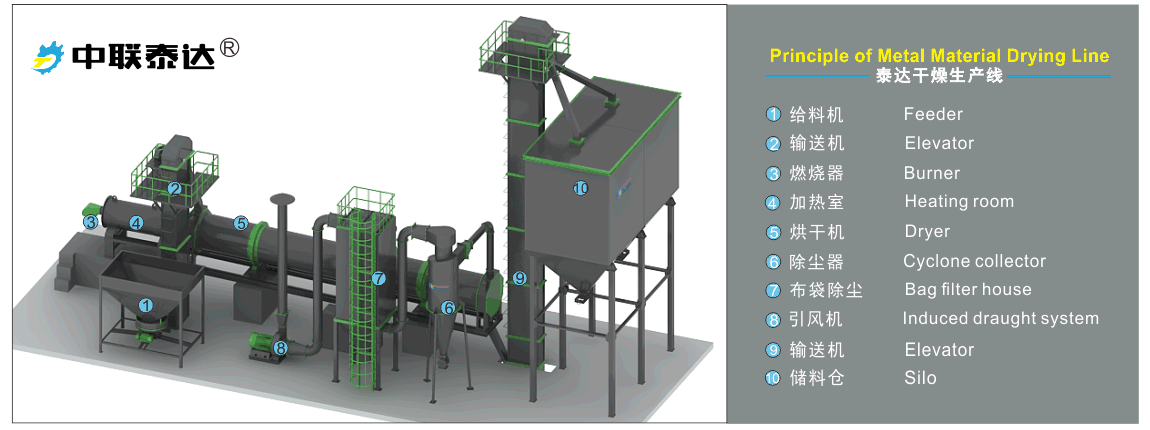

Whole system can match with various heat source and auxiliary equipment, which makes whole drying system can meet different drying demands of different customers.

Whole drying system holds flexible configuration. We can configure feeder, heat source, conveying, dust collecting, product conveying and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Item |

Gradient (%) |

Rotational speedr/min) | Inlet air temperature(℃) | Capacity (t/h) | Power(kw) |

| MGT600 | 3-5 | 3-8 | ≤850 | Different Materials Different Capacity. | 3 |

| MGT800 | 3-5 | 3-8 | ≤850 | 4 | |

| MGT1000 | 3-5 | 3-8 | ≤850 | 5.5 | |

| MGT1200 | 3-5 | 3-8 | ≤850 | 11 | |

| MGT1500 | 3-5 | 3-8 | ≤850 | 15 | |

| MGT1800 | 3-5 | 3-8 | ≤850 | 18.5 | |

| MGT2000 | 3-5 | 3-8 | ≤850 | 22 | |

| MGT2200 | 3-5 | 3-8 | ≤850 | 30 | |

| MGT2400 | 3-5 | 3-8 | ≤850 | 37 | |

| MGT2600 | 3-5 | 3-8 | ≤850 | 40 | |

| MGT2800 | 3-5 | 3-8 | ≤850 | 55 | |

| MGT3000 | 3-5 | 3-8 | ≤850 | 75 | |

| MGT3200 | 3-5 | 3-8 | ≤850 | 90 | |

| MGT3400 | 3-5 | 3-8 | ≤850 | 110 | |

| MGT3600 | 3-5 | 3-8 | ≤850 | 150 | |

| MGT4000 | 3-5 | 3-8 | ≤850 | 190 | |

| MGT4200 | 3-5 | 3-8 | ≤850 | 200 | |

| MGT4500 | 3-5 | 3-8 | ≤850 | 260 |