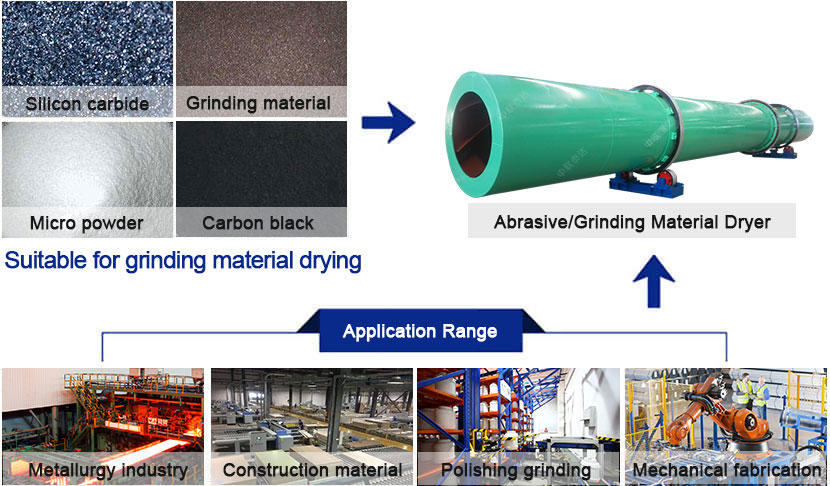

Taeda® grinding material/abrasives dryer can be used to dry various silicon-based and carbon-based grinding materials such as diamonds, refractories, silica, garnet sand, emery, waterjet sand, silicon carbide, corundum abrasives, polishing materials and etc. It is suitable for high-yield continuous efficient drying work for grinding materials with moisture content. It has the advantages of large output, low energy consumption, stable operation and strong pertinence. When designing, Taeda fully considers the characteristics of grinding materials. We formulate special structure and module to strengthen abrasion-resistant design of dryer. Cooperation with following various subsequent supporting modules ensures qualifed final moisture for ultra-fine powder grinding material and valuable abrasives (Carat measurement). Index for final products from Taeda grinding material dryer can reach a relatively better state. Taeda grinding material dryer has a high degree of mechanization, large production capacity, reliable operation, low energy consumption, high thermal efficiency, good material drying effect, easy automatic control and less labor force.

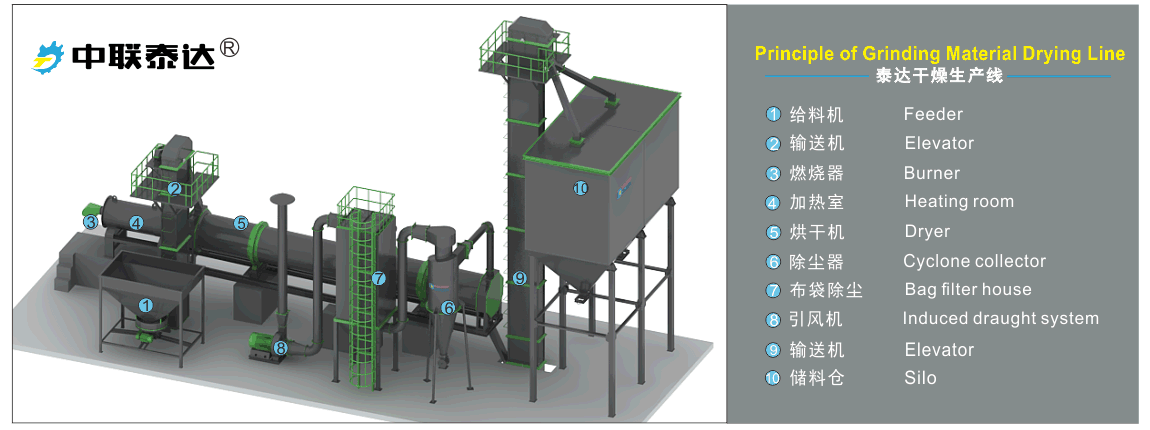

Taeda grinding material drum dryer adopts automatic centralized control, which makes dryer run continuously. Grinding materials are dispersed fully inside dryer and fully contact with hot air. Therefore, Taeda grinding material drum dryer can realize automatic control and consumes less labor force.

New Taeda grinding material drum drying adopts rational design and drying work can be finished in short time. Whole drying process is carried out in smooth procedure. It is featured in durable, long service life and low malfunction rate.

Taeda grinding material drying series can match with various heat sources like hot air furnace, pellet burner, gas burner and oil burner. Whole drying system costs less running cost and produces better quality final products. By adopting new insulation layer, whole system consumes less energy.

Whole drying system holds flexible configuration. We can configure hopper, feeder, heat source, conveying, dust collecting, product conveying and water scrubbing device. Professional team provides one-step service amd customizes suitable equipment ba

| Model | Diameter(M) | Length(M) | Slope(%) | Power(kw) |

Rpm (r/min) |

Occupation area(m²) |

| TDGT-12100 | 1.2 | 10 | 3-5% | 7.5 | 3-8 | 100 |

| TDGT-15120 | 1.5 | 12 | 3-5% | 10 | 3-8 | 150 |

| TDGT-15150 | 1.5 | 15 | 3-5% | 18.5 | 3-8 | 200 |

| TDGT-18120 | 1.8 | 12 | 3-5% | 11 | 3-8 | 260 |

| TDGT-22120 | 2.2 | 12 | 3-5% | 18.5 | 3-8 | 260 |

| TDGT-22140 | 2.2 | 14 | 3-5% | 18.5 | 3-5 | 300 |

| TDGT-22160 | 2.2 | 16 | 3-5% | 30 | 3-5 | 300 |

| TDGT-24140 | 2.4 | 14 | 3-5% | 30 | 3-5 | 350 |

| TDGT-24180 | 2.4 | 18 | 3-5% | 37 | 3-5 | 400 |

| TDGT-24220 | 2.4 | 20 | 3-5% | 37 | 3-5 | 450 |

| TDGT-30200 | 3.0 | 20 | 3-5% | 55 | 3-5 | 500 |

| TDGT-30220 | 3.0 | 22 | 3-5% | 75 | 3-5 | 500 |

| TDGT-40250 | 4.0 | 25 | 3-5% | 210 | 3-5 | 800 |