【Feeding size】:

【Feeding moisture】: 4-25%

【Capacity】: 0.5-200t/h

【Applicable material】: Ore slag, sand stone, clay, bentonite Suitable for drying petroleum proppant, frac sand, silica sand, bauxite and ceramsite materials.

Taeda® petroleum proppant frac sand dryer can be used for the drying of petroleum proppant, frac sand, quartz sand, alumina-vanadium ceramsite and coated sand. It is suitable for drying fracturing sand materials which require high output and continuous efficiency. It has advantages of large output, low energy consumption, stable operation and strong pertinence. During designing process, Taeda fully consider characteristics of petroleum proppant frac sand . Based on these characteristics, we formulate special structure and module to ensure cleanliness. It can dock with various subsequent screening combinations to ensure satisfying drying aim for 20 to 200 mesh product and make sure that indexes of final product reaches to optimal state. Taeda frac sand dryer is featured in high degree of mechanization, large production capacity, continuous operation, convenient operation, less malfunction, low maintenance cost and lower investment cost.

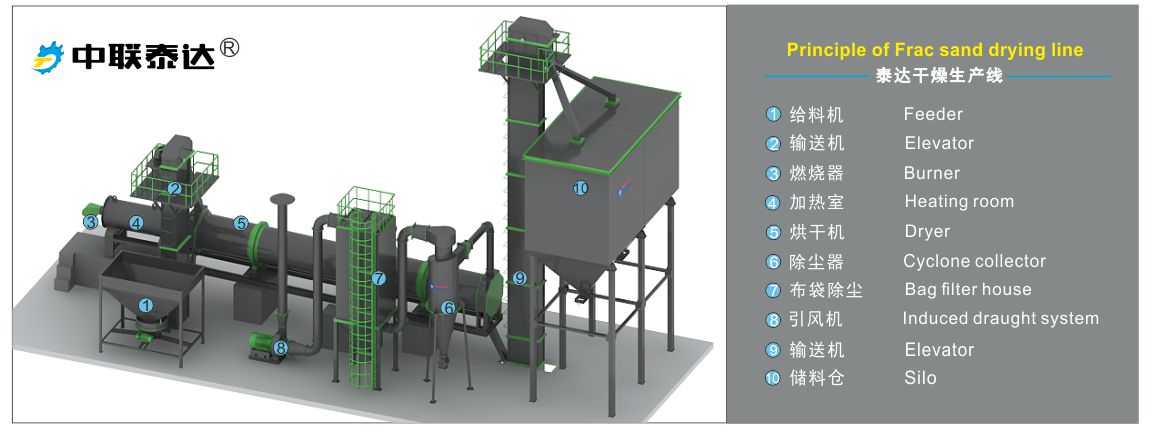

Taeda® frac sand dryer working principle:

Frac sand are sent to inner drum through silo and disc feeder so that to reach fair current drying process. Under the function of internal lifting plates, frac sand are lifted repeatedly and scatter in screw form for heat exchanging. During slow moving to discharging end, frac sand will absorb heat of hot air and rotary drum, which helps extend drying time. Therefore, Taeda frac sand dryer can reach optimal drying state. Dried frac sand will be discharged out of rotary drum dryer under hot air function.

Taeda frac sand dryer adopts automatic centralized control, which makes whole drying system run continuously. Materials will fully scatter in dryer and contact with hot air. Drying effect is superior than common drying system.

New frac sand drying machine is featured in reasonble design, quick drying speed and smooth drying process. By adopting superior texture, whole drying system holds longer service life and less malfunction rate.

Taeda new frac sand dryer can dock with coal gasifier, hot air, hot air furnace, pellet burner, diesel and gas. Total running cost is low and final products are with good quality. Thanks to low energy consumption, customer can recover cost in very short time.

Whole drying system holds flexible configuration. We can configure feeder, heat source, conveying, dust collecting, product conveying and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Item |

Gradient (%) |

Rotational speedr/min) | Inlet air temperature(℃) | Capacity (t/h) | Power(kw) |

| MGT600 | 3-5 | 3-8 | ≤850 | Different Materials Different Capacity. | 3 |

| MGT800 | 3-5 | 3-8 | ≤850 | 4 | |

| MGT1000 | 3-5 | 3-8 | ≤850 | 5.5 | |

| MGT1200 | 3-5 | 3-8 | ≤850 | 11 | |

| MGT1500 | 3-5 | 3-8 | ≤850 | 15 | |

| MGT1800 | 3-5 | 3-8 | ≤850 | 18.5 | |

| MGT2000 | 3-5 | 3-8 | ≤850 | 22 | |

| MGT2200 | 3-5 | 3-8 | ≤850 | 30 | |

| MGT2400 | 3-5 | 3-8 | ≤850 | 37 | |

| MGT2600 | 3-5 | 3-8 | ≤850 | 40 | |

| MGT2800 | 3-5 | 3-8 | ≤850 | 55 | |

| MGT3000 | 3-5 | 3-8 | ≤850 | 75 | |

| MGT3200 | 3-5 | 3-8 | ≤850 | 90 | |

| MGT3400 | 3-5 | 3-8 | ≤850 | 110 | |

| MGT3600 | 3-5 | 3-8 | ≤850 | 150 | |

| MGT4000 | 3-5 | 3-8 | ≤850 | 190 | |

| MGT4200 | 3-5 | 3-8 | ≤850 | 200 | |

| MGT4500 | 3-5 | 3-8 | ≤850 | 260 |