【Feeding size】:

【Feeding moisture】:

【Capacity】:>25 million carat/h

【Applicable material】:

Working principle:

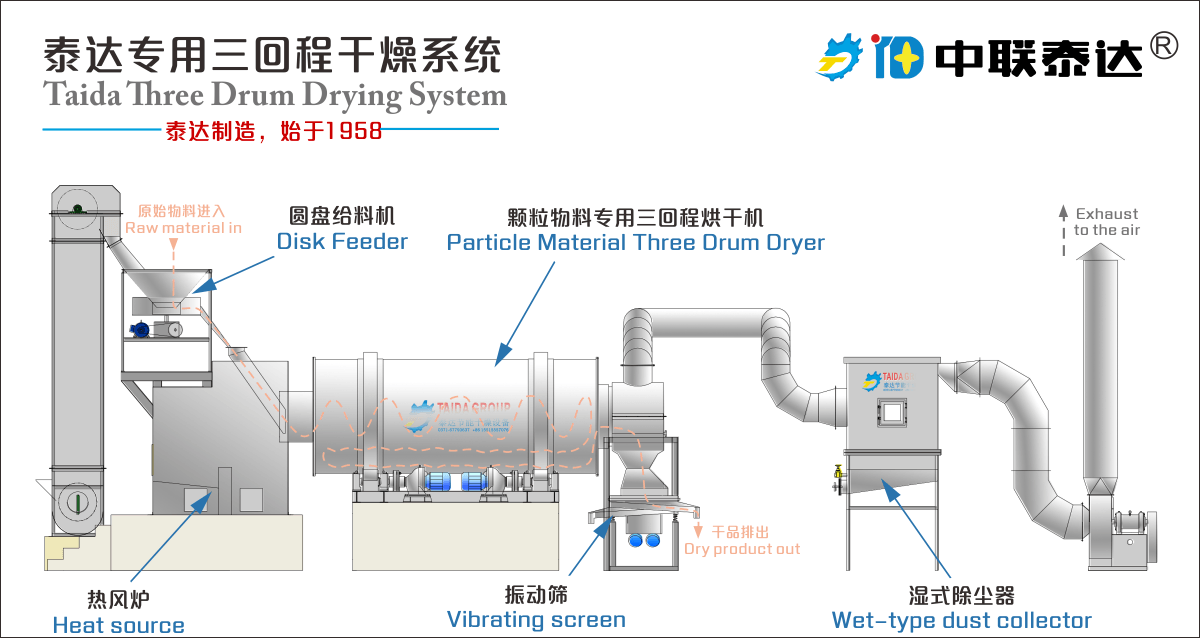

Diamond stone materials are sent to diamond stone dryer through vibrating feeder. Inner drum of dryer is a cone shape drum which incline slightly. Diamond stone and hot air enter through higher end. Fair current contact between diamond stone and hot air makes moisture evaporated. With the rotation of drum and under the function of gravity, diamond stone enters lower end. After three pass, dry products arrives at discharging port and are elevated to screening section. There are lifting plates made by special texture on inner wall of diamond dryer drum. These lifting plates will lift and scatter diamond stone which increase contact surface between material and hot airflow. In this way, drying ratio is improved and materials are driven forward. Before leaving dryer, wet exhaust gas will pass pulse bag filter first and remaining material in exhaust gas will be caught. Many customers order Taeda new diamond stone drying system to replace old drying production lines (microwave drying line, industrial drying oven and disc drying line) and Taeda receives many sound feedbacks from different customers.

Taeda diamond stone dryer is specially designed for diamond stone drying. Its capacity can reach more than 2.5 million carat. It can adopt electricity and gas heating mode. Taeda new diamond stone dryer can reduce moisture of diamond stone from 15% to below than 1% one time. It holds large capacity and good drying effect.

Taeda diamond stone dryer adopts automatic centralized control mode which makes it run continuously. Diamond stone materials fully contact with hot air which makes sure good drying effect and strong drying ability. Drying task can be finished in short time and whole drying process is done in a smooth procedure. Superior manufacturing texture of Taeda diamond stone dryer guarantees longer service life and low malfunction rate.

Taeda diamond stone dryer is characterized by wide application range, high production capacity, strong evapration ability, simple structure, small footprint and low investment/running/maintenance cost. Heat source system can match with coal gasifier, coal hot air furnace, pellet burner, diesel burner and natural gas burner to produce proper hot air.

Whole drying system holds flexible configuration. We can configure feeder, heat source, conveying, dust collecting, product discharging and packing unit based on customers' requirements. Taeda diamond stone dryer can be applied for various industries and various customers so that to make sure each customer can find suitable drying equipment from Taeda.

Item | Capacity (t/h) | Power (Kw) | |||

| Slag | Fly Ash | Clay | Sand | ||

| TDLT320.1 | 5~10 | 4 | 4~6 | 10~15 | 11 |

| TDLT320.2 | 10~15 | 6 | 6~8 | 15~20 | 11 |

| TDLT325.1 | 20~25 | 8 | 8~12 | 20~25 | 15 |

| TDLT325.2 | 25~30 | 10 | 12~15 | 25~30 | 15 |

| TDLT328 | 30~35 | 15 | 15~20 | 35~40 | 22 |

| TDLT330.1 | 35~40 | 20 | 20~25 | 40~45 | 30 |

| TDLT330.2 | 40~45 | 25 | 25~30 | 45~50 | 30 |

| TDLT332.1 | 45~50 | 30 | 30~35 | 50~60 | 44 |

| TDLT332.2 | 50~60 | 35~40 | 35~40 | 60~70 | 44 |

| TDLT336 | 60~70 | 40~45 | 40~45 | 70~80 | 60 |

| TDLT338 | 70~80 | 45~50 | 45~50 | 80~90 | 60 |

| TDLT340 | 80~90 | 50~60 | 50~60 | 90~100 | 74 |