【Feeding moisture】: 5-70%

【Capacity】: 50-5000kg/h

【Applicable material】: Dehydrated vegetable, granule feedstuff, drug and medicine materials, Chinese wolfberry, red dates, medicinal herbs, melons, fruits, etc.

【Application field】: Applied for dry vegetable, flower, food, medicine, feedstuff, snack, material and environmental protection fields.

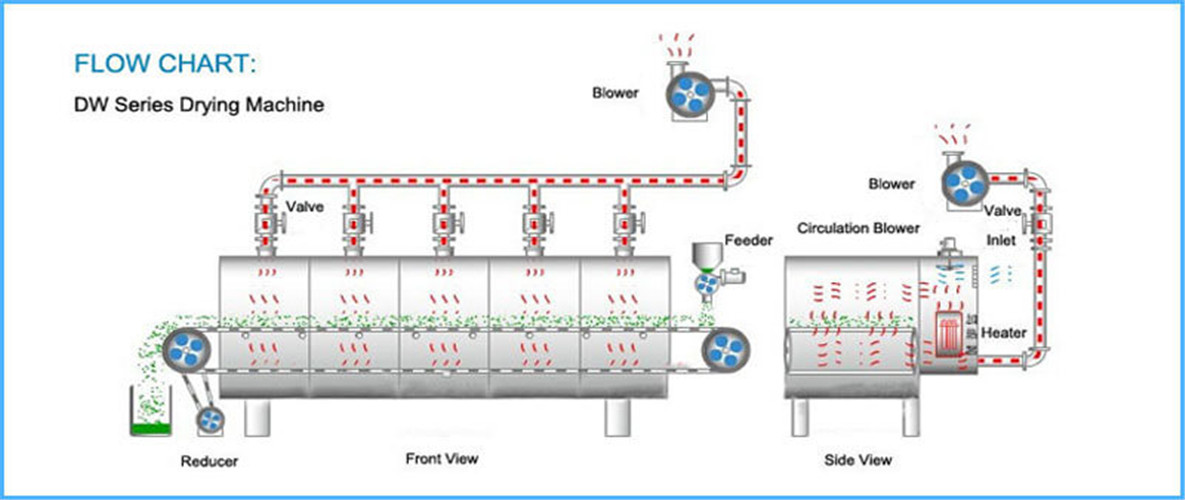

During working process, materials will be evenly distributed on belts of dehydrated vegetable mesh belt dryer. Under the driving of transmission device, drying belt will move back and forward in dryer. Hot air will pass through raw materials. Vapor is discharged out from moisture exhaust hole so that to reach drying aim. Mesh belts adopted are 12 to 60 mesh steel wire belt. Length of dryer chamber is composed of mutiple standard sections. In order to save space, mesh belt dryer can be made into multi-layer type. Common designs are 2-chamber/3-layer and 2-chamber/5-layer, Length ranges from 6 to 40 meters. Effective width ranges from 0.6 to 3m.

By adopting automatic electrical centralized control, whole drying system can run continuously. Materials are evenly scattered in dryer and fully contact with hot air. Drying effect is good.

Whole drying equipment is featured in reasonble design, stable running performance and smooth drying process. By adopting superior texture, Taeda belt dryer holds longer service life and less malfunction rate.

Taeda dehydrated vegetable mesh belt dryer is optimzed aimed on dehydrated vegetables. Dryer is designed with scientific air duct. Low temperature circulating wind will continuously pass through material layer and belt layer. Thickened insulation shell makes energy sealed in drying chamber and dried products with better quality.

Whole drying system holds flexible configuration. We can provide hopper, feeder, heat source, conveying, dust collecting, product conveying and packing unit ba

| Model | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-10 | DW-2-20 | |

| Unit no. | 4 | 5 | 4 | 5 | 4 | 5 | 10 | |

| Belt width m | 1.2 | 1.6 | 2 | |||||

| Drying stage length m | 8 | 10 | 8 | 10 | 8 | 10 | 20 | |

| Material thickiness mm | ≤60 | |||||||

| Operation temperature ℃ | 50-140 | |||||||

| Steam pressure Mpa | 0.2-0.8 | |||||||

| Steam consumption Kg/h | 120-130 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | 450-1200 | |

| Drying period h | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.2-1.5 | 0.5-3 | |

| Drying capacity Kg water/h | 60-160 | 80-220 | 75-220 | 95-250 | 100-260 | 120-300 | 240-600 | |

| Installed power kw | 11.4 | 13.6 | 11.4 | 13.6 | 14.7 | 15.8 | 36.8 | |

| Overall dimensions | Lm | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| Wm | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 | |

| Hm | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 | |

| Total weight Kg | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 | |