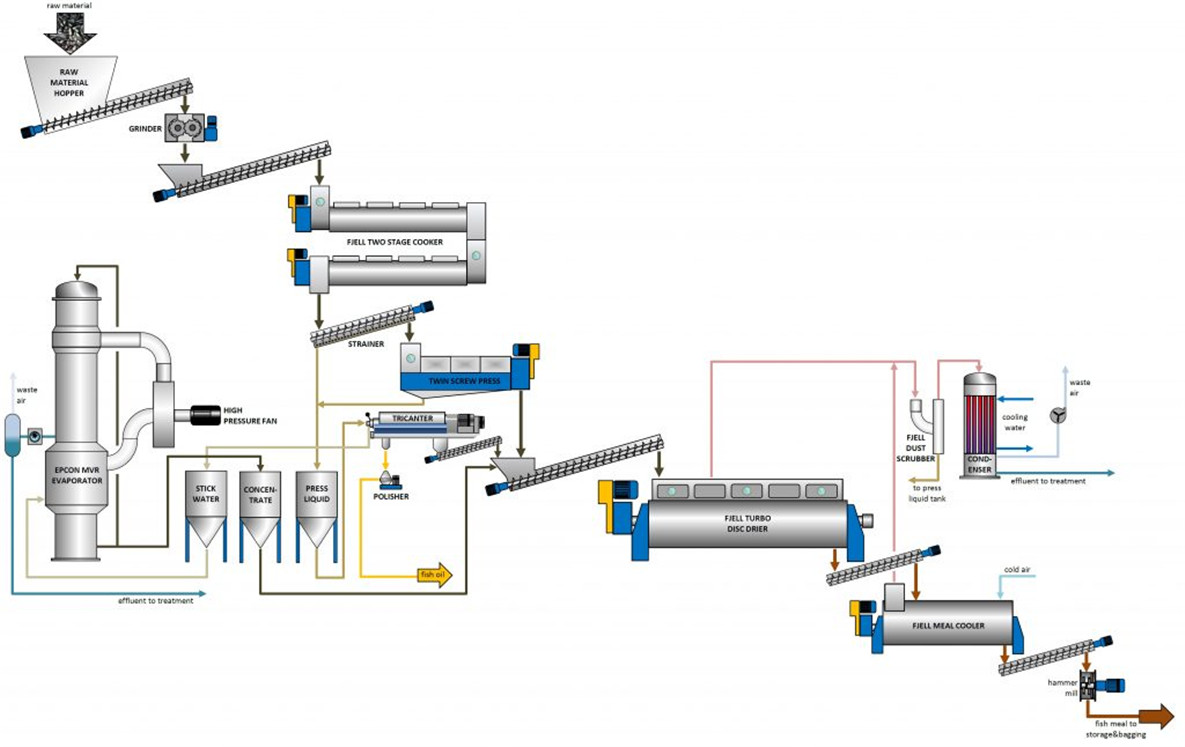

The wet-method whole fish meal production line is one advanced fish meal processing technology worldwide at present. Consisting of five major parts: fish meal production, oil refining system, double-effect falling film concentration system and deodorization device for environment protection, and electrical general control, it can make fish meal and fish oil of high quality out of leftovers of waste and odd substances (such as head, skin, bowel, etc.) and little rough fish which is not edible, especially out of whole fish which is very resourceful, and it shows great economic benefits and social benefits.

We are a professional manufacturer of complete fishmeal and oil plant in China. The processing capacity ranges from 50Ton, 80Ton, 100Ton, 150Ton, and 200Ton to 300Ton raw material per 24 hours which can be used for both land and floating. We also improve fish oil refinery plant with processing capacity 10T, 20T, 30T and 35T crude fish oil in 24 hours, which could be part of the fish meal plant. We are manufacturers for both fishmeal and fish oil plants in China.

When the temperature is too high, there will no oxide skin. This machine is characterized by good abrasive resistance. Therefore, it has a long service span.

There are various inlet temperatures. This machine can make the materials at outlet presented as small particles or powder which provides convenience for next process.

There is a whole set of equipment which holds 10 to 200t/h output capacity. We can also customize drying machine according to customer’s demands.

Reasonable design can avoid the leakage of materials.It adopts special seal structure made from tin steel piece between cover body and machine, which prevents leakage under micro negative pressure.

| Specifications | Capacity (t/24h) | weight (t) | Power(kW) | Size(m) |

| D-XH-50 | > 50 | 19.0 | 37.0 | 8.5× 1.9× 2.6 |

| D-XH-80 | > 80 | 22.5 | 45.0 | 10.0× 1.9× 2.6 |

| D-XH-100 | > 100 | 26.0 | 55.0 | 11.5× 1.9× 2.6 |

| D-XH-150 | > 150 | 37.0 | 75.0 | 12.0× 2.2× 3.2 |

| D-XH-200 | > 200 | 45.0 | 90.0 | 13.0× 2.2× 3.3 |

| D-XH-250 | > 250 | 50.0 | 110.0 | 13.5× 2.2× 3.3 |

| D-XH-300 | > 300 | 55.0 | 110.0 | 14.0× 2.2× 3.3 |