【Feeding size】:

【Feeding moisture】: 5% to 25%

【Production capacity】:1 to 100t/h

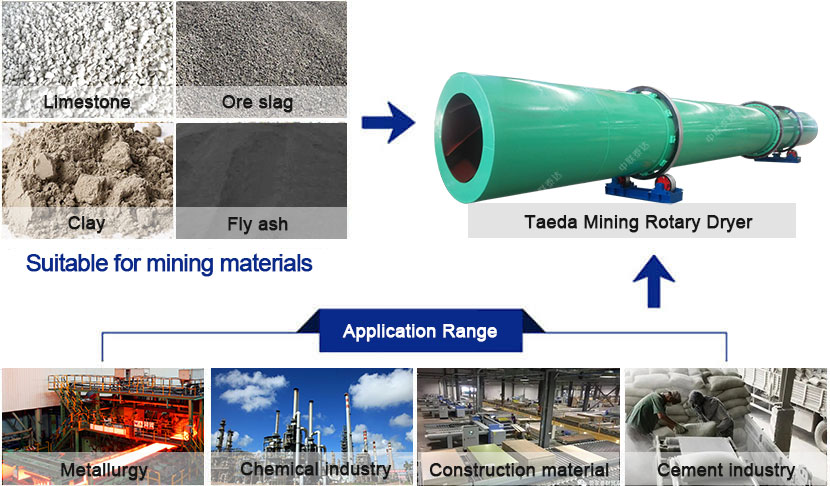

【Applicable material】:Suitable for drying limestone, stone material, sand, dolomite, bentonite and clay from beneficiation, construction material, me

Taeda® limestone dryer is a kind of rotary drum type dryer specially designed for limestone drying. It makes use of hot air to realize drying aim and optional fuels can be coal, gas, oil and biomass pellets. Through fuel burning, there will be hot air produced to dry limestone, calcium carbonate block and limestone powder with 4% to 25% moisture content. Taeda limestone dryer is suitable for continuous and efficient drying work for calcium stone. Taeda limestone dryer is featured in large capacity, small footprint, less energy consumption, stable running performance and specific design for limestone drying.

Major ingredient of limestone is calcium carbonate. It always appear in forms of calcite and aragonite. Limestone holds good resistance to chemical, acid and corrosion. Limestone has very wide application ranges like construction, cement, paper making, printing ink, chemical and rubber industry. We have rich limestone resources in China.

Before being applied in industrial fields, limestone always should be crushed, screened and dried. Drying is major procedure for limestone processing. Drying effect has great impact on quality of final limestone. Therefore, customer should choose proper limestone dryer supplier. There are multiple limetsone dryer manufacturers in market and quality of dryer is not same. As a drying manufacturer with long history, limestone dryer from Taeda holds better drying effect and whiteness of material is not affected. Taeda limestone dryer is featured in stable performance, high capacity and low running cost. It is a proper choice for customers to dry limestone materials.

Aimed at features of limestone, Taeda adopts new design suitable for drying limestones. Taeda limestone dryer can reduce moisture to lower than 5% one time from 25%. Whole system is featured in large capacity, low energy consumption and low running cost.

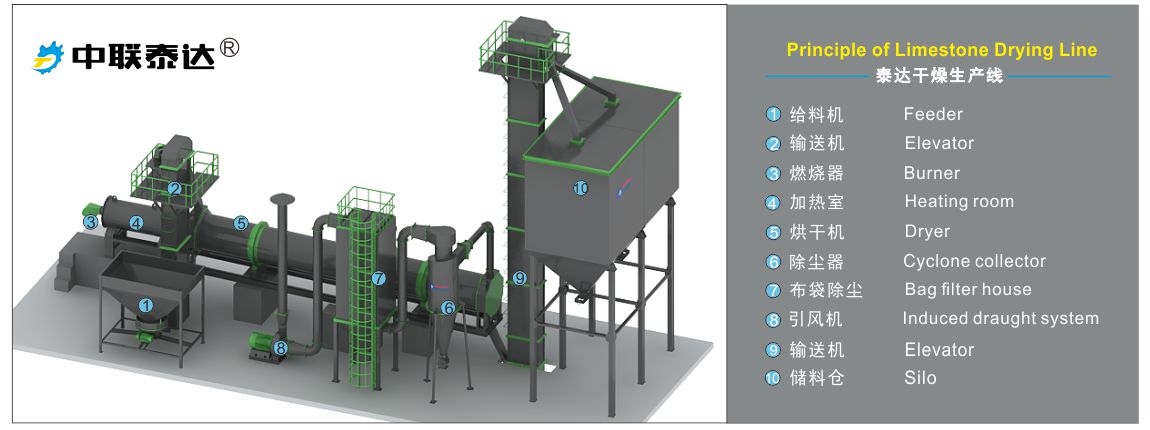

Taeda limestone rotary drum dryer adopts automatic centralized control, which makes dryer run continuously. Limestone materials are dispersed fully inside dryer and fully contact with hot air. Thus, both drying effect and drying ability are good. Materials can be dried fast and whole drying process is smooth. With superior construction texture, Taeda limestone dryer holds longer service life and low malfunction rate.

Taeda limestone dryer holds wide application range, high capacity, strong evaporation capacity, simple structure, small footprint, lower investment and maintenance cost. Heat source can be matched with coal gasifier, coal hot air furnace, pellet burner, diesel burner and gas burner to produce hot air needed for drying work.

Whole drying system holds flexible configuration. We can configure hopper, feeder, heat source, conveying, dust collecting, product conveying and water scrubbing device. Professional team provides one-step service amd customizes suitable equipment ba

| Item |

Gradient (%) |

Rotational speedr/min) | Inlet air temperature(℃) | Capacity (t/h) | Power(kw) |

| MGT600 | 3-5 | 3-8 | ≤850 | Different Materials Different Capacity. | 3 |

| MGT800 | 3-5 | 3-8 | ≤850 | 4 | |

| MGT1000 | 3-5 | 3-8 | ≤850 | 5.5 | |

| MGT1200 | 3-5 | 3-8 | ≤850 | 11 | |

| MGT1500 | 3-5 | 3-8 | ≤850 | 15 | |

| MGT1800 | 3-5 | 3-8 | ≤850 | 18.5 | |

| MGT2000 | 3-5 | 3-8 | ≤850 | 22 | |

| MGT2200 | 3-5 | 3-8 | ≤850 | 30 | |

| MGT2400 | 3-5 | 3-8 | ≤850 | 37 | |

| MGT2600 | 3-5 | 3-8 | ≤850 | 40 | |

| MGT2800 | 3-5 | 3-8 | ≤850 | 55 | |

| MGT3000 | 3-5 | 3-8 | ≤850 | 75 | |

| MGT3200 | 3-5 | 3-8 | ≤850 | 90 | |

| MGT3400 | 3-5 | 3-8 | ≤850 | 110 | |

| MGT3600 | 3-5 | 3-8 | ≤850 | 150 | |

| MGT4000 | 3-5 | 3-8 | ≤850 | 190 | |

| MGT4200 | 3-5 | 3-8 | ≤850 | 200 | |

| MGT4500 | 3-5 | 3-8 | ≤850 | 260 |