【Capacity】: 2.5-50t/h

【Power】: 6-170Kw

【Heat source】: Coal, oil, natural gas, timber.

【Applications】:

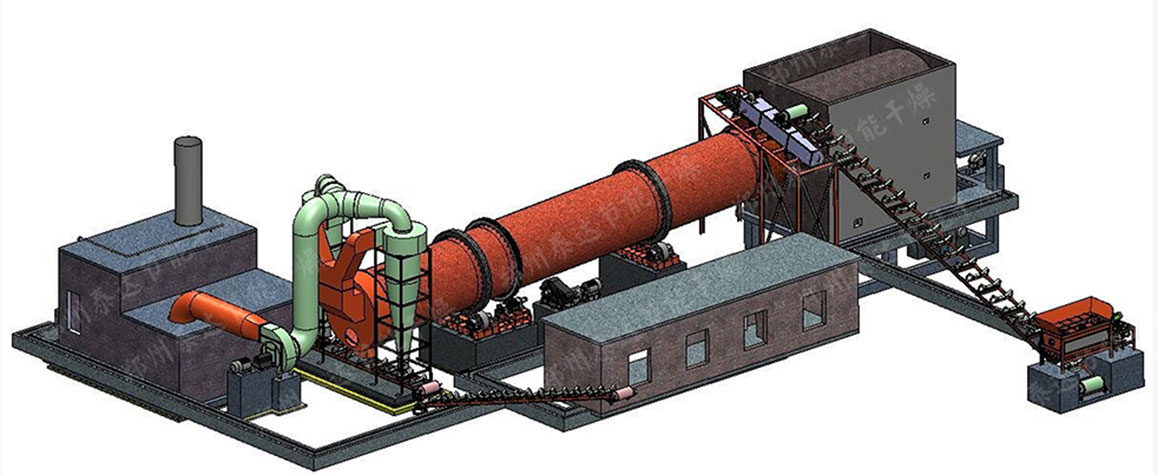

Lignite dryer or lignite coal dryer is a drying machine mainly used for drying lignite coal. Traditional drying method adopts centrifugal machine for dehydration, and the equipment is expensive and has low production capacity and small dehydration extend. Generally it can only reduce about 10% of the water and there is still 15%-20% of water content. Lignite rotary dryer adopts new technology on which coal materials will be crushed first and scattered evenly in drum. Raw materials will be dried by heating power. Reasonble design makes whole lignite drying disposal process continuous, efficient and automatic. The water content of the moist lignite coal processed by brown coal dryer can be reduced from 25%~30% to below 13%, and the moist lignite coal can be used as bunker coal, thus improving the coal washing and dressing technology and having excellent economic, social and environmental benefits.

Working principle: Wet coal slime/coal slurry/lignite are evenly sent to rotary drum coal slurry dryer by feeding conveying system. After entrance into rotary dryer, wet materials will be led to oblique lifting area. Under the function of internal lifting plate, raw materials will fully exchange heat with hot air and evaporate partial moisture. Meanwhile, temperature of hot flue gas will drop sharply. Preheated wet materials enter medium drying stage and majority moisture will be evaporated here. Materials and flue gas will repeatedly mix and exchange heat until reach to ideal final moisture. Then, qualified dried materials will be discharged out dryer drum and sent to appointed place for storage. Hot air produced by heat source will enter dryer drum. After finishing heat exchanging, tail gas which contains large amount of vapor and dust will pass through cyclone and discharged to atmosphere after secondary purification of bag filter or water type dust removal system.

Aimed at free moisture and bound moisture contained in Lignite Coal, Taeda Lignite Coal rotary drum dryer can reduce moisture of Lignite Coal materials to lower than 13% one time. Whole system holds large capacity, low energy consumption and less investment cost.

New internal structures strengthens cleaning and heat conduction function to scattered materials. Meanwhile, wall-sticking phenomenon of lignite dryer can be effectively removed. Taeda lignite dryer holds better adapability to material moisture and stickness.

Running parameters of Taeda lignite dryer can be property of different batch material. Correspondingly, there will be stable and thorough material curtain formed in dryer drum, which makes mass heat exchange more sufficient. Final product particle size and moisture can be controlled ba

New ignition control system strictly adopts reliable programmed ignition controller so that to prevent ignition explosion in dryer and realize linkage protection. It only costs one minute for ignition process and no smoldering process.

| Item |

Gradient (%) |

Rotational speedr/min) | Inlet air temperature(℃) | Capacity (t/h) | Power(kw) |

| MGT600 | 3-5 | 3-8 | ≤850 | Different Materials Different Capacity. | 3 |

| MGT800 | 3-5 | 3-8 | ≤850 | 4 | |

| MGT1000 | 3-5 | 3-8 | ≤850 | 5.5 | |

| MGT1200 | 3-5 | 3-8 | ≤850 | 11 | |

| MGT1500 | 3-5 | 3-8 | ≤850 | 15 | |

| MGT1800 | 3-5 | 3-8 | ≤850 | 18.5 | |

| MGT2000 | 3-5 | 3-8 | ≤850 | 22 | |

| MGT2200 | 3-5 | 3-8 | ≤850 | 30 | |

| MGT2400 | 3-5 | 3-8 | ≤850 | 37 | |

| MGT2600 | 3-5 | 3-8 | ≤850 | 40 | |

| MGT2800 | 3-5 | 3-8 | ≤850 | 55 | |

| MGT3000 | 3-5 | 3-8 | ≤850 | 75 | |

| MGT3200 | 3-5 | 3-8 | ≤850 | 90 | |

| MGT3400 | 3-5 | 3-8 | ≤850 | 110 | |

| MGT3600 | 3-5 | 3-8 | ≤850 | 150 | |

| MGT4000 | 3-5 | 3-8 | ≤850 | 190 | |

| MGT4200 | 3-5 | 3-8 | ≤850 | 200 | |

| MGT4500 | 3-5 | 3-8 | ≤850 | 260 |